- 3 -

BMS

RS GND

RSA

RSB

18

ENG

c.pCO sistema +0300057EN rel. 1.1 - 13.04.2015

J3 Disp

+Vterm

LH

J4 FBus J5 CAN

J3 Disp

J4 FBus

J6 BMS

+Vterm

J3 Disp

J4 FBus

J6 BMS

+Vterm

G

G0

G

G0

G

G0

24 Vac

L

N

230 Vac

24 Vac

L

N

J25 BMS2 J26 FBus2

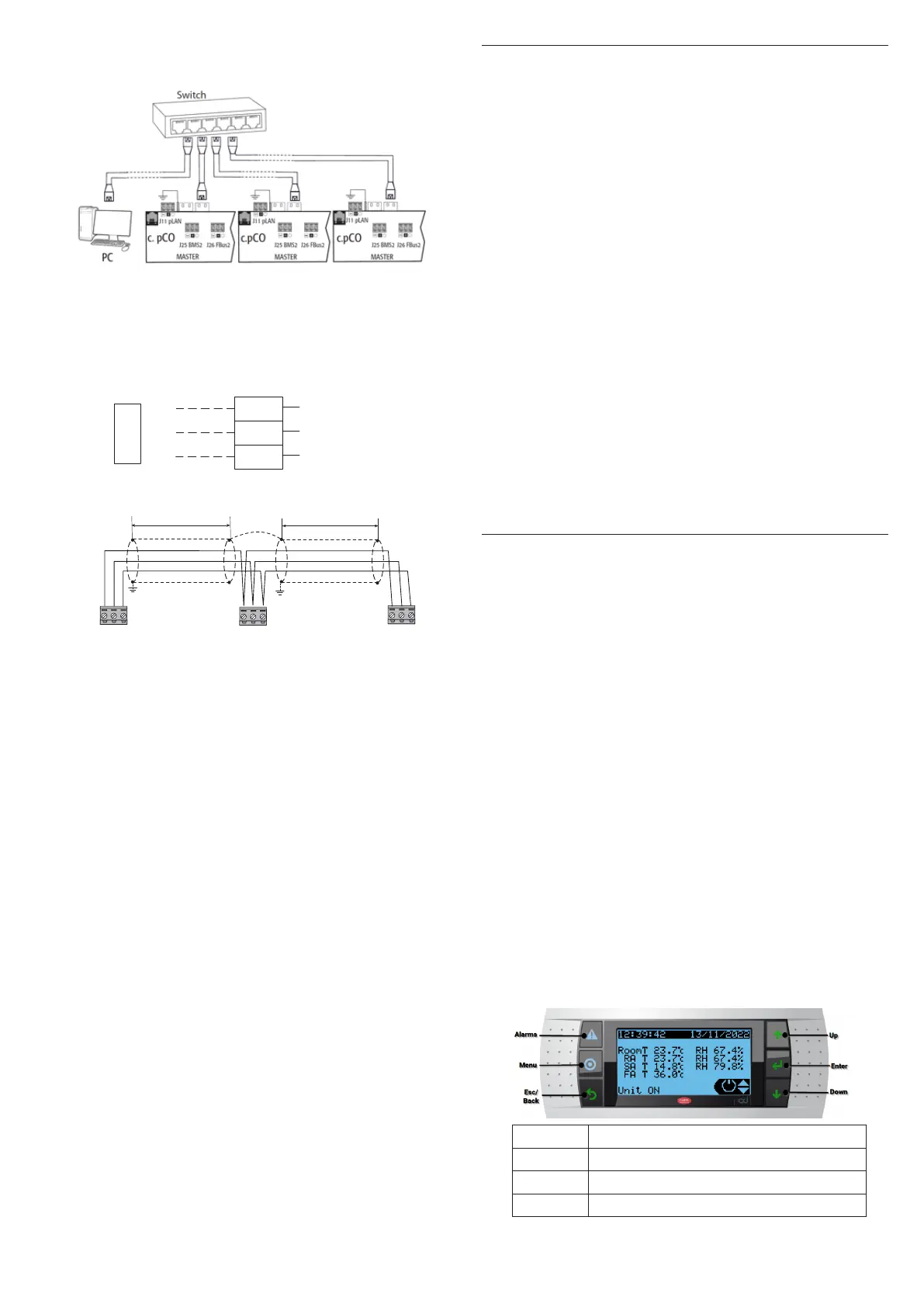

J11 pLAN

c.pCO

G

G0

J25 BMS2

J26 FBus2

J11 pLAN

c.pCO

G

G0

J25 BMS2J26 FBus2

J11 pLAN

c.pCO

G

G0

Fig. 4.e

The procedure for earthing the shield is described in the corresponding

paragraph.

Case 2: multiple boards connected to a Master/Slave network powered

by diff erent transformers (with G0 not earthed); this is a typical application

of multiple boards inside diff erent electrical panels. If the network is more

than 100 m long, the 120 Ω, ¼ W terminating resistor is required.

J3 Disp

+Vterm

LH

J4 FBus J5 CAN

J3 Disp

J4 FBus

J6 BMS

+Vterm

J3 Disp

J4 FBus

J6 BMS

+Vterm

G

G0

G

G0

G

G0

230 Vac

24 Vac

L

N

230 Vac

24 Vac

L

N

230 Vac

24 Vac

L

N

R = 120 Ω

R = 120 Ω

J25 BMS2 J26 FBus2

J11 pLAN

c.pCO

G

G0

J25 BMS2

J26 FBus2

J11 pLAN

c.pCO

G

G0

J25 BMS2 J26 FBus2

J11 pLAN

c.pCO

G

G0

230 Vac

24 Vac

L

N

230 Vac

24 Vac

L

N

230 Vac

24 Vac

L

N

R = 120 Ω

R = 120 Ω

Fig. 4.f

Important: the earth connection (if any) should be made only on

one point of the earth line (same earthing terminal for all controllers).

The procedure for earthing the shield is described in the corresponding

paragraph.

Optically-isolated serial port

This is the case of serial ONE - BMS1, serial TWO - Fieldbus 1 and the built-

in ports serials THREE and FOUR on optically-isolated models. Regardless

of the type of power supply or earthing, use a 3-wire shielded cable

connected as shown in the fi gure. If the network is more than 100 m

long, the terminating resistor is required.

J25 BMS2 J26 FBus2

J11 pLAN

c.pCO

G

G0

J25 BMS2

J26 FBus2

J11 pLAN

c.pCO

G

G0

J25 BMS2 J26 FBus2

J11 pLAN

c.pCO

G

G0

R = 120 Ω

R = 120 Ω

Power

supply

Fig. 4.g

The procedure for earthing the shield is described in the corresponding

paragraph.

Procedure for earthing the shield

The shield of the serial cable is earthed diff erently according to the

length, as shown in the fi gure (where A=FBus terminal, B=BMS terminal).

Case 1: distance between controllers less than 0.3 m: earth only one end

of the cable.

L < 300 mm

L < 300 mm

AB B

Fig. 4.h

Case 2: distance between controllers greater than 0.3 m: two possibilities.

- earth one end with a bridge between the shields

L >300 mm

L > 300 mm

AB B

Fig. 4.i

- earth both ends of the cable (no bridge between shields).

L >300 mm

L > 300 mm

AB B

Fig. 4.j

Multipleunitsusinganetworkswitch:

4.5 BMS – Modbus Connection

Connect to supplied terminals in electrical box; refer

Specications document for wiring detail, sheet 2 grid

reference D0, reproduced below.

Figure 1: RS485 terminal block in electrical box

Figure 2: Carel recommendations for shield grounding

4.6 Stand Alone

Option 1:

1. Install optional Carel pGD1 remote display (Item no.

201-000-379) inside building, connection to Carel

c.pCO master controller J10 port. Cable RJ11.

2. Connect Room temperature and humidity sensor

directly to Carel c.pCO master controller. See

Specication sheet for wiring schematic/sheet 2 for

wiring details of Room temperature input) and Room

RH%.

Option 2:

In absence of a Carel remote pGD1 the unit can be

controlled using the on-board Carelc.pCO master controller

with its included digital display.

4.7 Remote on/off

The unit’s UC8 Controller has an input for a remote on/

off function on terminal ‘On’, signal return is terminal ‘0V’.

When used the remote on/off terminals should connect to a

voltage-free relay contact. When not used the remote on/off

terminals should be shorted (‘looped’).

4.8 Economiser Wiring

See Specications document for wiring schematic/

sheet 1, lower left corner.

UC8 Master-Slave Connection

5. ECONOMISER OPTION

The Economiser package that is factory tted consists of

two opposed blade dampers, one for the fresh air and the

other for the return air. They come complete with individual

damper motors controlled using a 0–10V dc signal. The

package also includes a weatherhood assembly that is

usually supplied as a separate item for tting on site. It is

important that the installation instructions for the tting of

the weatherhood are followed otherwise it is possible some

water ingress from rain could occur.

If the outdoor temperature as well as the enthalpy is below

that of the return air, the fresh air damper can be opened

and the return air damper closed to provide the rst stage of

cooling.

The air damper’s minimum and maximum openings can

be adjusted using the Master Controller (c.PCO) Menu/

Settings/Damper Cong. Each of the dampers can have

settings for use in both the occupied and unoccupied

modes. The settings for opening based on an optional CO

2

air quality sensor can also be adjusted. Many installations

may require a minimum fresh air introduction of 10–15%

(refer local Building Code regulations) and the stop may be

set on site to facilitate this. Ensure the air ow entering the

unit is equal between full return air and full Economiser by

adjusting the damper stops on both Return and Fresh

air dampers.

6. START-UP PROCEDURE

6.1 Before starting the compressors

1. Before working on the unit isolate mains power.

2. Remove the shipping wedges from beneath each

compressor. Check that each compressor is securely

mounted.

3. Check oil level as per label attached to each

compressor.

4. Check the mains power and controls wiring are correct.

5. Check tightness of all electrical connections.

6. Check the air lters have been correctly installed.

7. Check that all indoor fan motors can freely rotate.

8. Check the supply voltage between each phase and

neutral.

9. Check air diffusers and ductwork are open.

10. Apply mains power to the unit by closing the mains

isolating switch.

11. Before starting the compressors a four hour delay

period is required to allow the crankcase heaters to

drive any liquid refrigerant out of the compressor oil.

Mains power must be switched on during this four hour

delay period.

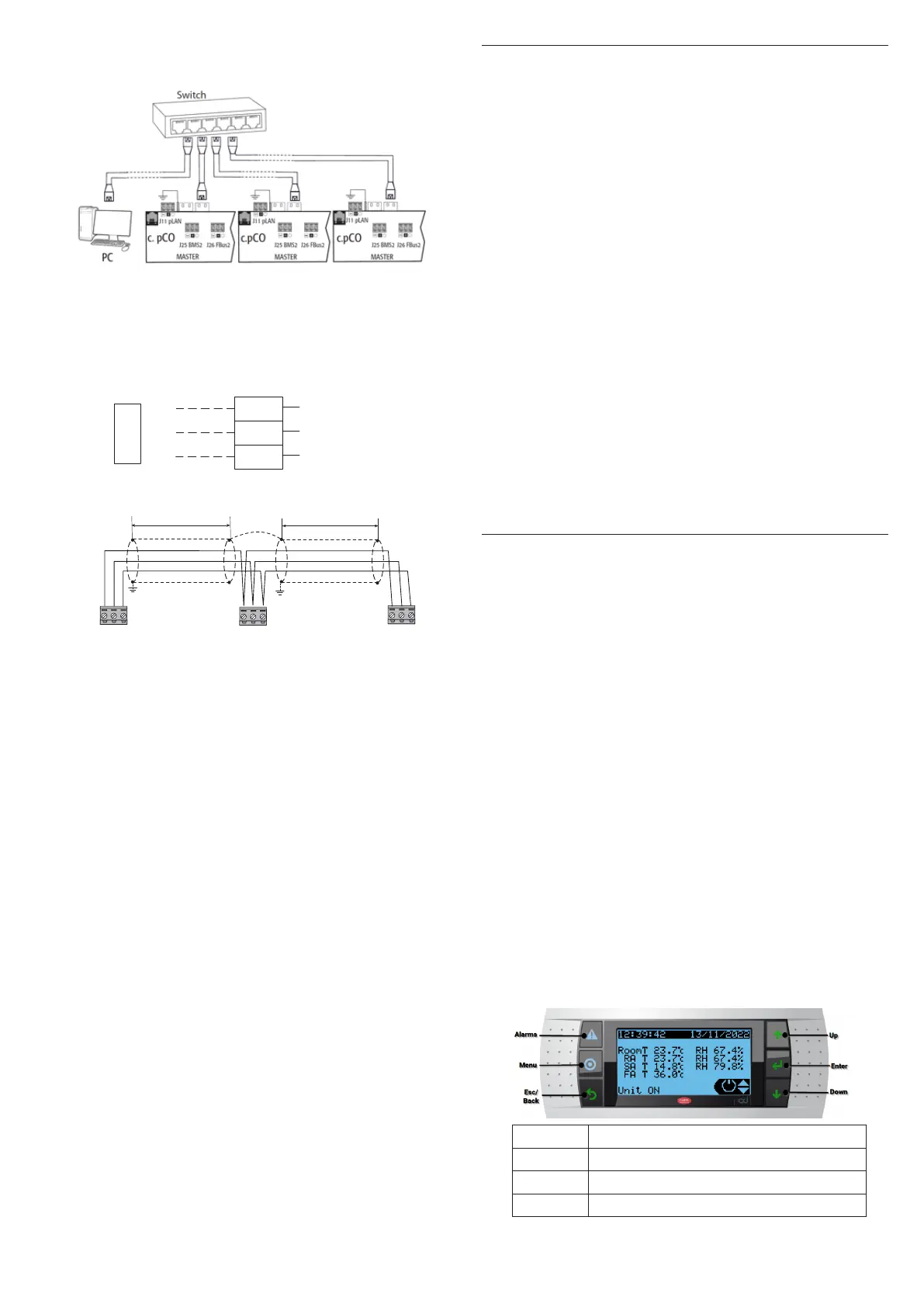

6.2 Master Controller Display (Carelc.pCO)

Button Function

Alarm System Alarm indication and Reset

Menu Go to Main menu

Esc Return to previous page or Exit menu

Loading...

Loading...