- 4 -

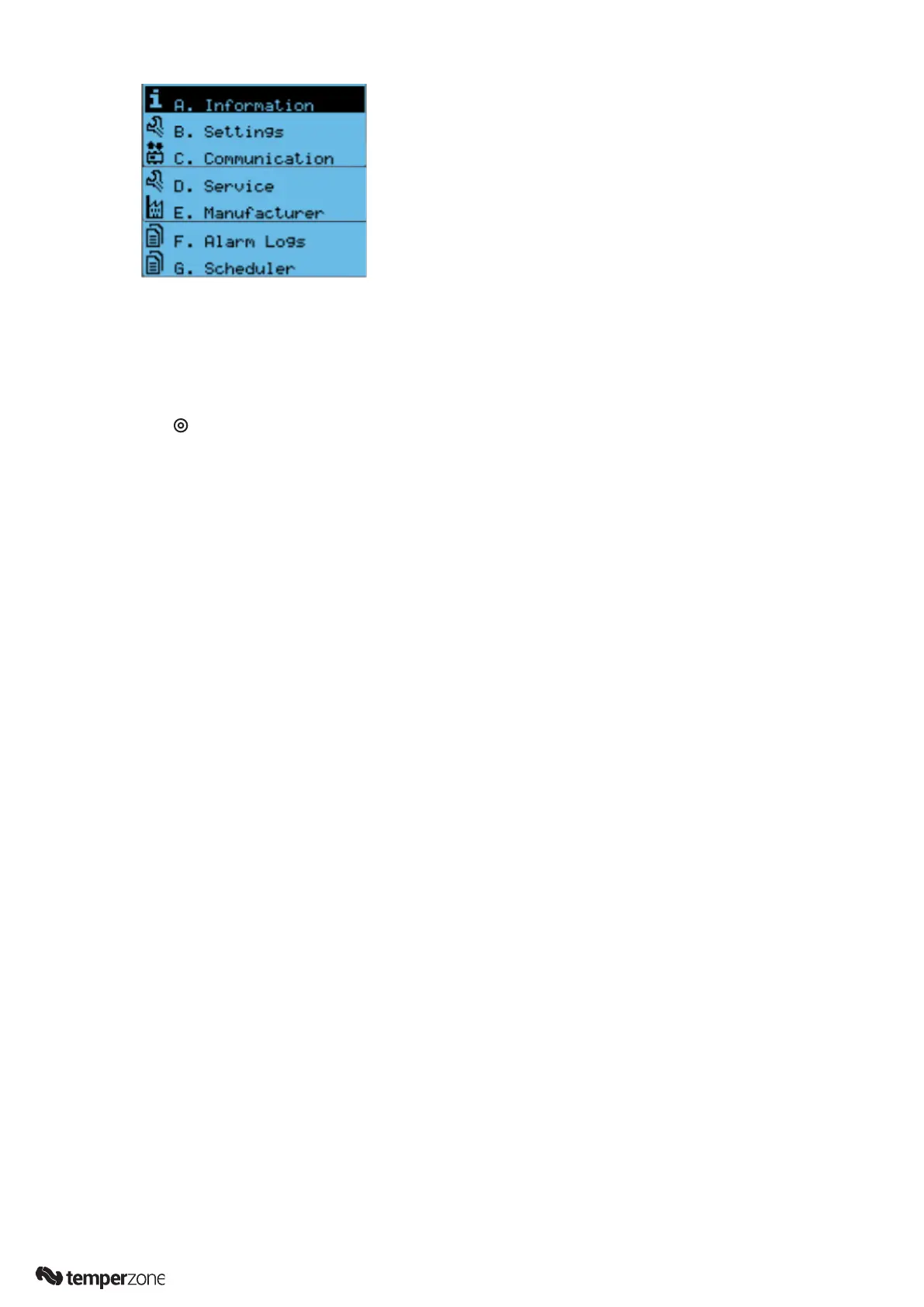

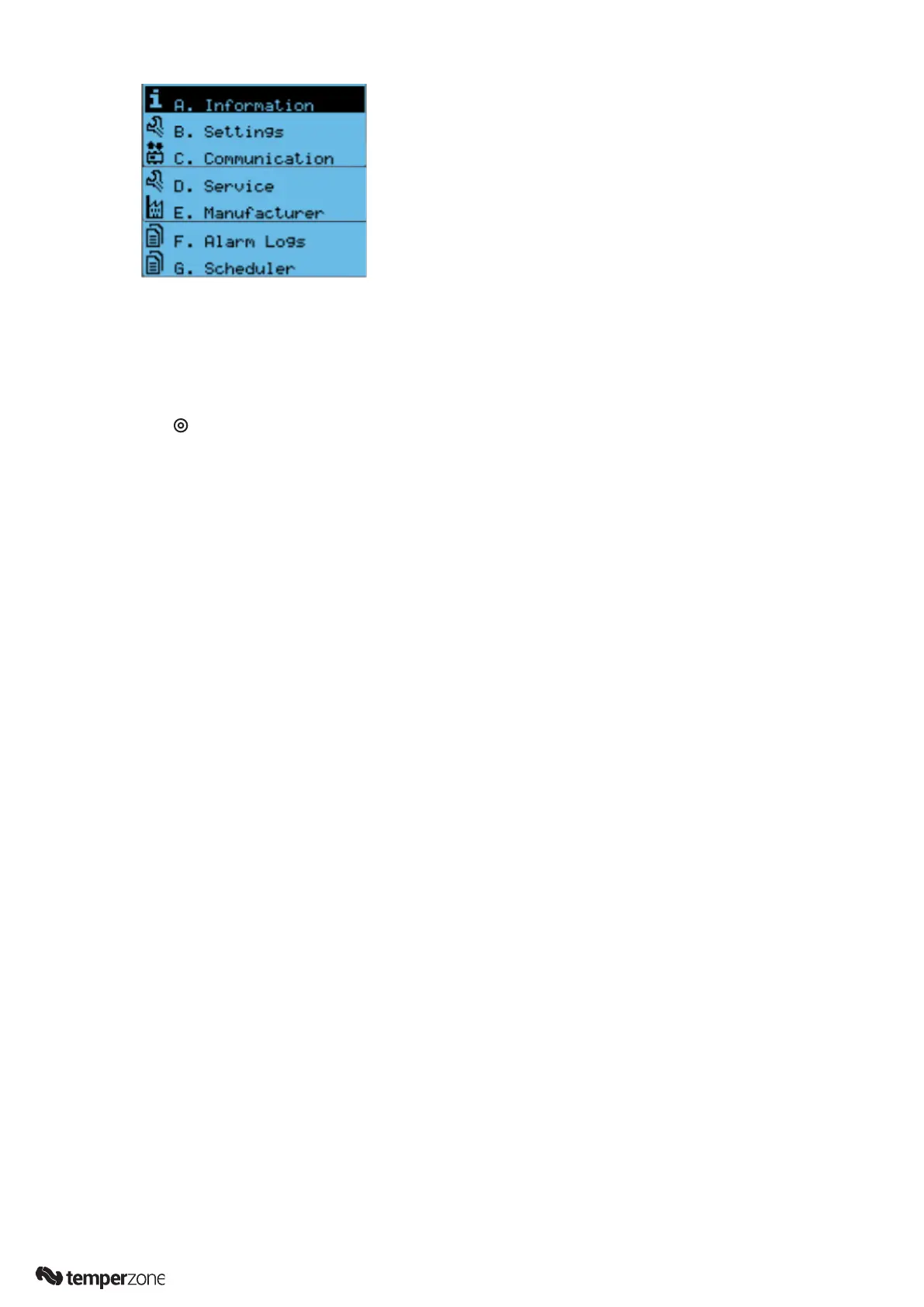

Main Menu:

6.3 Commissioning

After the four hour delay period has expired (see step 11 in

section 6.1) complete the following procedure. You can use

the Commissioning Sheet (supplied with the unit) to help

you.

1. From the initial screen of the Master Controller press

Menu button to bring up the Main menu.

2. Scroll down and select ‘D. Service’.

Enter password ‘2100’.

3. Scroll down and select ‘Manual Control’.

4. Scroll to ‘Manual Airow’. First enter airow requirement

in litres/second then select ‘Yes’ under enable to start

indoor fan operation. (refer Note below)

5. Measure air ows from duct work to verify air ows,

record current draw on each fan and then disable

‘Manual Airow’.

6. Scroll to sub menu ‘B. Settings’ and sselect ‘Fan

Cong’. Change fan mode to either ‘Airow’, ‘Fixed

Speed’ or ‘0-10VDC’.

7. Change airow setpoint on following pages to match

veried airows. If using xed speed, set speed

in % and cross check current draw against airow

measurements. Otherwise set airow in litres/second as

per measured values.

8. Scroll back to ‘D. Service’ menu and manual ‘control

menu’.

9. Navigate to ‘Manual Unit Capacity’ and select capacity

requirement. 100% = all compressor stages on. NOTE:

i. This does not correspond to compressor speed.

ii. Unit will need to be turned on by keypad to allow the

capacity control to function.

10. Allow compressors to run for a short duration while

checking for any unusual noises or vibrations.

11. Measure the current draw on each phase to the

compressor motor and to each fan motor. Check the

readings against the specied values in the wiring

diagram or Specication sheet.

12. Check each refrigeration system’s information, from

the Main menu select ‘Information’, then ‘UC8’ (refer

Appendix I for more detail). Also check Information/

Power usage.

13. Once testing is complete disable ‘Manual Unit

Capacity’.

14. Remove any swarf found inside the unit and touch up

any external paintwork damage incurred in transit to

prevent corrosion.

Note:

Setting the indoor fan speed too low can bring risk of frost

forming on the indoor coil with potential nuisance frost

protection trips on cooling, possibly even unit lock-out, and/

or HP trips on heating.

Setting the indoor fan speed too high can bring a risk of

blowing moisture off the ns of the indoor coil and into the

supply air duct. Water could then start leaking from the

supply air grilles and corrosion of ducting may occur.

Setting the indoor fan speed too high can also bring a risk

of ‘over-condensing’ (when the unit is heating) which in turn

could cause the unit to perform more outdoor coil de-ice

cycles than necessary.

Outdoor fans do not necessarily start rotating immediately

after the compressor is started. The fans may run-on for a

short period after the compressor stops.

The indoor fan will reduce speed if in heating mode and the

condensing temperature is too low to automatically allow

the condenser coil to warm up. The fan speed may also

slightly reduce when in Latent Cooling mode, if this option is

enabled.

Loading...

Loading...