22 EN

EN

3. Bin lift operation

37878

05-2017

3.11

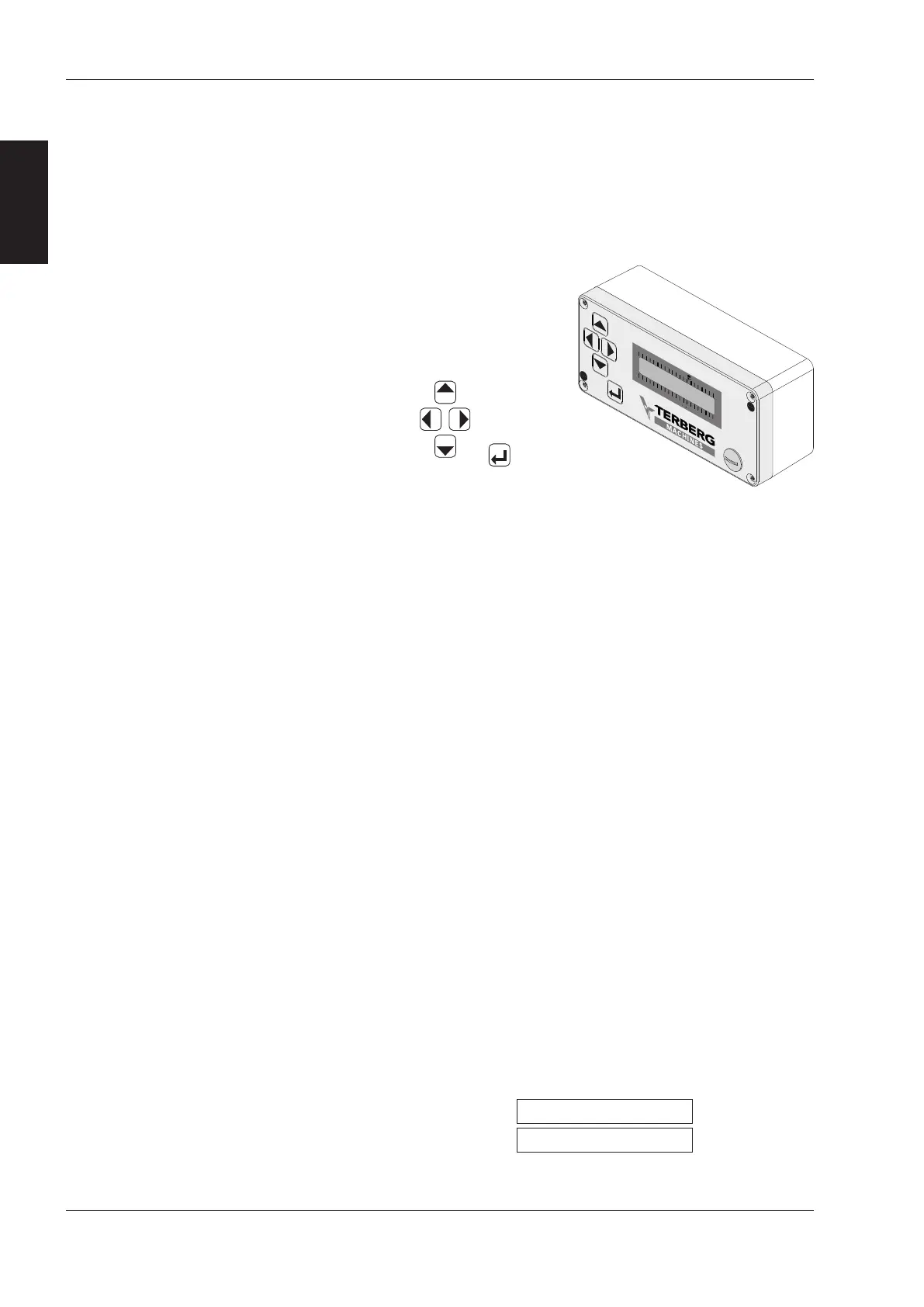

Diagnostic System

ã Terberg Machines B.V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any way,

electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

The Diagnostic System is mounted on the left or right hand side of the bin lift, depending on the country.

A

ll actions made by the bin lift are monitored by the SBC-10 processor. A number of actions as well as faults are

stored in the ‘historical alarm list’ that can store up to 200 messages.

The alarm list can be consulted during maintenance and when rectifying faults, see also chapter 4.6 ‘Trouble

shooting’ - section ‘Alarm messages’.

As an option the program can be extended with a ‘bin counter program’, with which it is possible to count the

number of 2-wheel bins and 4-wheel containers emptied.

The program comprises 5 levels:

3.11.1 Home screen / messages

3.11.2 Monitor

- Position of L/H and R/H chairs

- Digital inputs

- Analogue inputs

- Digital outputs

- Analogue outputs

- Voltage of electrical system

- Pressure of hydraulic system

3.11.3 Bin counter (optional)

3.11.4 Configuration*

- Machine number (code 1001); This is a unique number, for ordering parts and/or for questions

about the bin lift you must always give this number as reference.

- Fitting date (code 1002); This is the date on which the bin lift was fitted on the refuse

collection vehicle.

- End of warranty date (code 1003); This is the end date of the warranty period.

- Historical alarms (code 1004); A number of actions as well as faults are stored in the

‘historical alarm list’, this can store up to 200 messages. This list

can be consulted during maintenance and when rectifying faults,

see also chapter 4.6 ‘Trouble shooting’ - section ‘Alarm messages’.

- Time and date (code 1005); Here you will find the system date and GMT time (no summer- or

wintertime is specified).

3.11.5 Settings

- Compaction start options; 2-wheel bins / 4-wheel containers / number of bins/containers before

packer start.

- Bin dump timer / Wait after dump.

- Single Man Trade (SMT); Standby position / lift height.

- Raise lifting chairs during reverse (Travel height).

- Automatically change over from 2- to 4-wheel and/or from 4- to 2-wheel bins/containers.

- Shaking; Maximum number of shakes via manual operation.

Shake frequency.

Activate or deactivate the variable shake mode.

Setting the 5 shake timers.

Restoring the Terberg default shake timer settings.

Shake switch positions and number of shakes.

- N6 comb sensor; setting time delay.

- 2-Wheel bins; Up- and down speed.

* When you key in an unknown code in the configuration

program, the following text will be shown:

Access to the program has now been blocked for 2 minutes.

After these 2 minutes the program returns to the data entry screen and you can continue.

3

3

44

5

5

66

77

88

99

1

0

10

1

1

11

1

2

12

1

3

13

1

4

14

1

5

15

2

2

00

11

1

9

19

2

0

20

2

1

21

2

2

22

2

3

23

2

4

24

2

5

25

2

6

26

2

7

27

2

8

28

2

9

29

3

0

30

3

1

31

1

8

18

1

6

16

1

7

17

D

I

A

G

N

O

S

TI

C

S

Y

S

TE

M

*

T

E

R

B

E

R

G

O

M

N

I

D

E

K

A

*

D

a

t

u

m

:

0

1

-

0

4

-

1

6

NO ACCESS !

Basisscherm / meldingen

*TERBERG OMNIMAX*

TIJD UU:MM:SS

*

TERBERG OMNIMAX*

DATUM DD/MM/JJ

Niveau 1

Niveau 2

Up

Down

Confirm (ENTER)

NextBack

Loading...

Loading...