EN 37

EN

37878

05-2017

4. Maintenance and cleaning

4.5

Maintenance

(schedule)

ã Terberg Machines B.V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any way,

electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

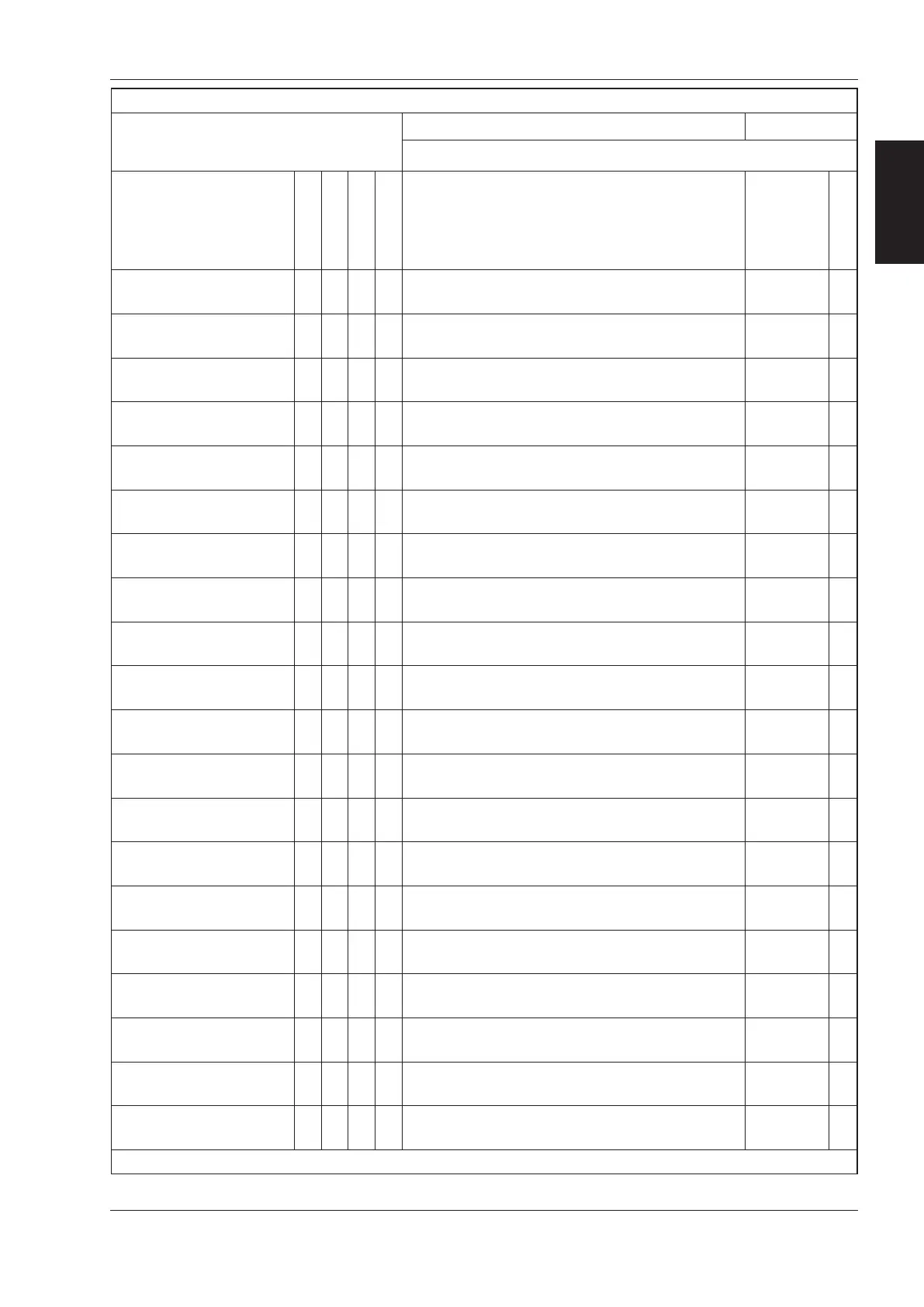

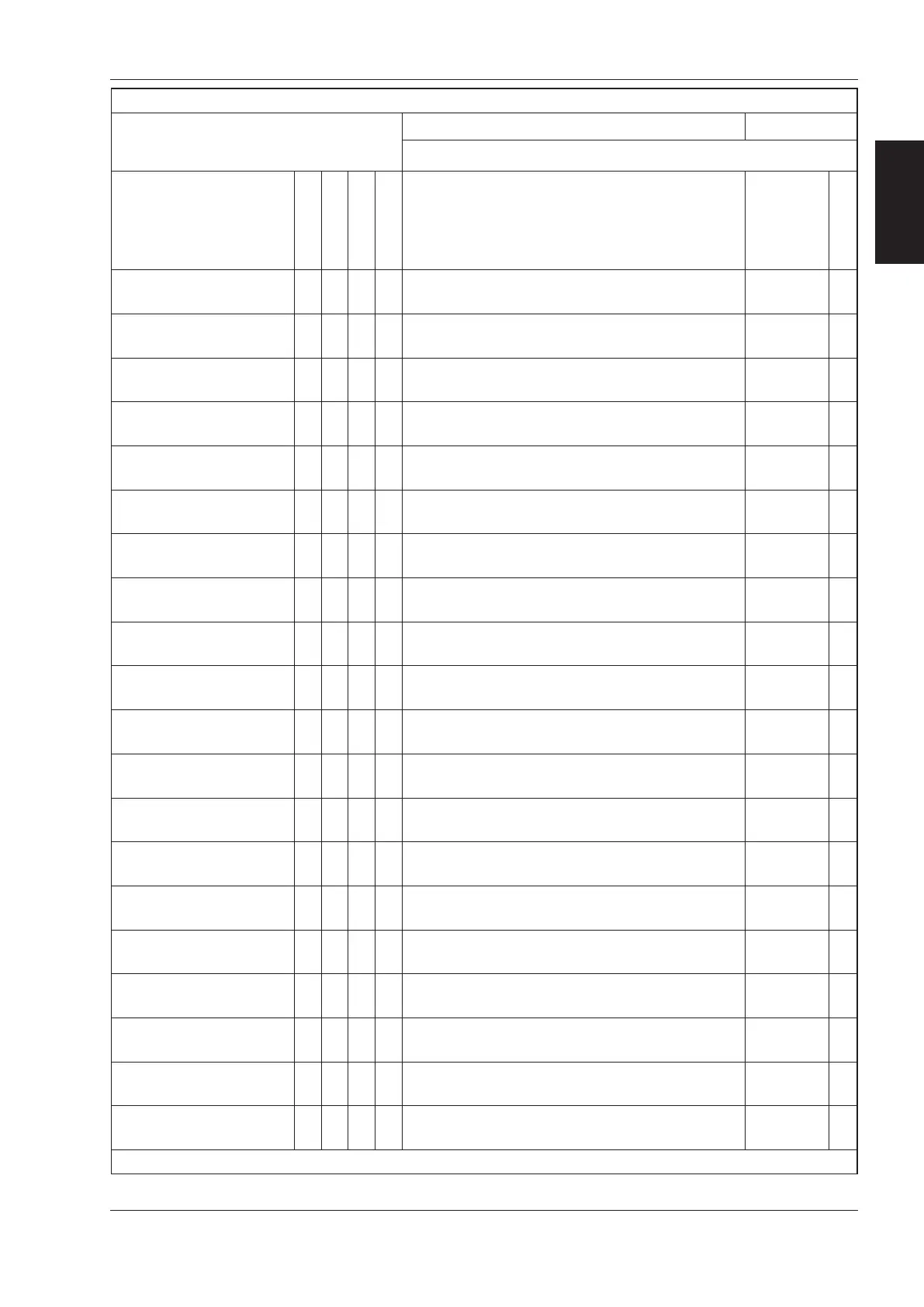

Maintenance schedule

Machine type: OmniDEKA

Date:

Page 1 of 2

Machine number:

Daily

Weekly

6-weekly

Annual

Description

Additional

information:

see

paragraph

Carried out

Spray cleaning

XXXX

Use a high pressure cleaner to clean the bin lift.

Do not direct the jet at electrical components or decals.

4.1

Footboards and

handle bars (if present)

XXXX

Check the footboards and handle bars of the bin lift for

damage, correct working and fixation.

--

Controls

-XXX

Check the working by carrying out all possible functions using

empty bins/containers.

--

Bin security switch and

pedal arm (cycle start)

-XXX

Check the action springs.

4.2

Rear Protection Device

(RPD)

-XXX

Check the operation of the underwalk protection (RPD),

remove any accumulated dirt at the sensors.

2.5

Start and 4-wheel

recognition sensors

- X X X

Check the working of these sonar sensors.

--

DIN pick-up arms and

chair lock (mechanical)

-XXX

Check the chair lock when opening the L/H DIN pick-up arm.

Check that the fall down locks close in the tilted position.

4.2

Instruction and

safety decals

-XXX

Damaged instruction and safety decals must be replaced

immediately.

--

Lubrication

-XXX

Individual greasing points; apply grease (≥ 1 cc).

Greasing system; administer 5 pumps of grease (≥10 cc).

4.2

Teeth pick-up combs

-XXX

Check that the teeth of the pick-up comb are aligned.

--

Bump stops, screens and

protective windows

-XXX

Check the fixation and condition of the bump stops, screens

and protective windows.

--

Dust curtains (tarpaulin)

-XXX

Check the dust suppression curtains for tears.

--

Faults

-XXX

Check the bin lift for any faulty or damaged parts.

--

Oil leak

-XXX

Check that there are no oil leaks.

--

Wiring

-XXX

Check the wiring for any damage.

--

Bin/container locking

--XX

Check the clamp gap as per drawing between pick-up comb

and locking plate.

4.3

Proximity switches

--XX

Check the setting.

4.3

DIN pick-up arms

(if present)

--XX

Check the springs.

Check the distance between the pick-up arms.

4.3

Footboards

(if present)

--XX

Check the springs and sensors when fitted.

4.3

Fixing points and

bolt / nut connections

---X

Check security of all fixing points of the bin lift and

check all bolt / nut connections.

4.4

Faults identified must be rectified before the bin lift is put into service!

Loading...

Loading...