40 EN

EN

4. Maintenance and cleaning

37878

05-2017

4.6

Trouble shooting

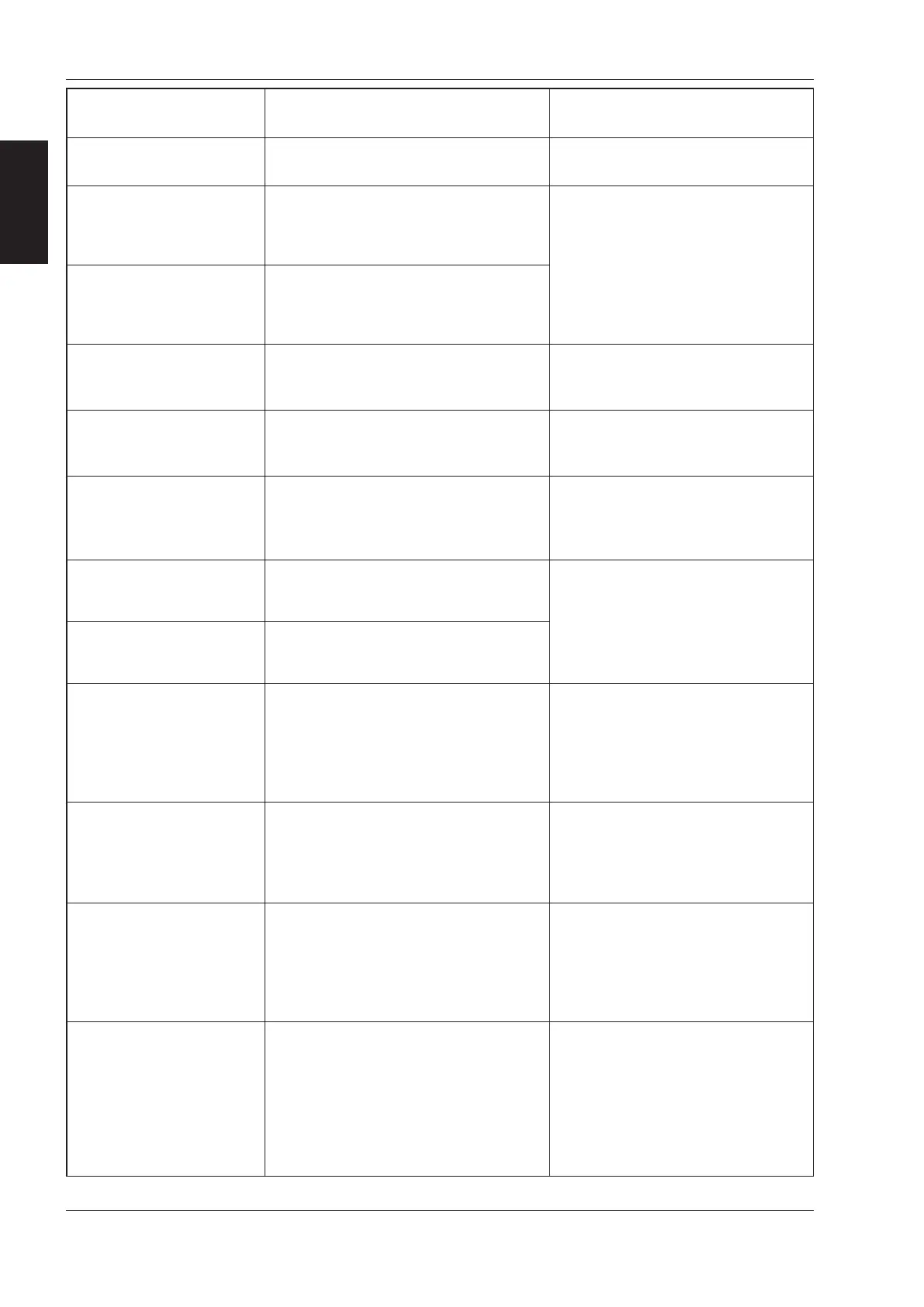

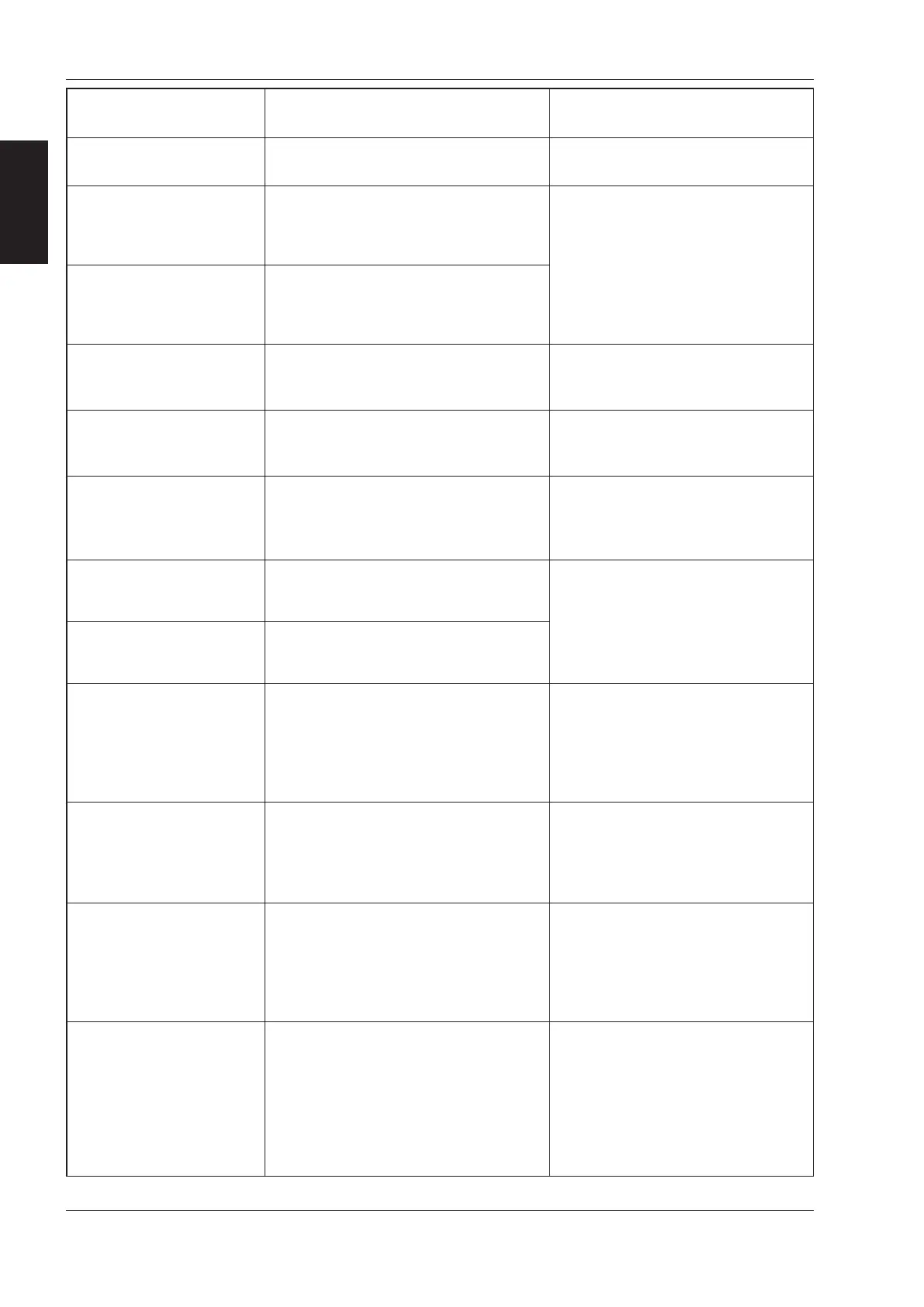

Alarm message 01 to 13

ã Terberg Machines B.V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any way,

electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

01: EMERGENCY

STOP

Emergency stop signal is active.

Check emergency stop buttons on the bin lift and

refuse body.

02: TRUCK IN

REVERSE

Reverse gear signal is active. A reverse gear signal is

produced on the refuse body / truck chassis.

If you want to use the bin lift please put the

gearbox into neutral gear.

03: REVERSE L/H

RAISE ERROR

The L/H lifting chair has not lifted up to the safe

lifting height for travel in the time it usually takes to

lift it up. The error is reset when reverse gear is

switched off or when chair is on travel position.

Reverse errors usually occur when the bin lift

receives no oil from the refuse body in reverse

situations. Or the PTO / pump is not active during

reverse. So make sure the bin lift can receive

hydraulic energy during reverse situations.

04: REVERSE R/H

RAISE ERROR

The R/H lifting chair has not lifted up to the safe

lifting height for travel in the time it usually takes to

lift it up. The error is reset when reverse gear is

switched off or when chair is on travel position.

05: CHAIR LOCKING

PIN ERROR

Unexpected movement of R/H chair.

R/H chair moves without the controller energises

any R/H valves to make it move.

This is probably caused by the L/H chair lifting up

the other side by the trade lock pin or any other

mechanical link during 2-wheel mode.

06: CHAIR LOCKING

PIN ERROR

Unexpected movement of L/H chair.

L/H chair moves without the controller energises

any L/H valves to make it move.

This is probably caused by the R/H chair lifting up

the other side by the trade lock pin or any other

mechanical link during 2-wheel mode.

07: ADJUST ZERO

WEIGHING SYSTEM

Static zeroing request for weighing systems

TMDW9004 / TMDW9009 / TMDW8010.

Normal message during start up in the morning.

Please perform a zero adjust sequence by holding

down the R/H up and down button simultaneous-

ly in domestic mode for a few seconds until the bin

lift moves up automatically.

08: LOW SPEED CHECK

OIL SUPPLY L/H

L/H chair is moving up too slow in automatic mode,

it takes too much time before half height position is

reached.

Check oil supply from the truck, check valves

and / or pumps.

09: LOW SPEED CHECK

OIL SUPPLY R/H

R/H chair is moving up too slow in automatic

mode, it takes too much time before half height

position is reached.

10: ERROR LOCK PIN

The bin lift is in trade (4-wheel) mode and there is

a mechanical / hydraulic lock pin mounted on this

bin lift, still there is too much position difference

noticed between the L/H and R/H chair position.

Check if the bin lift runs level without the chair

locking pin.

Check for mechanical axial and radial play from

the position sensors or adjoined bearings.

Check / calibrate the position sensors.

Check / calibrate the proportional valves.

11: HOPPER PLATE

SWITCH

The hopper plate door is open, the bin lift is ready

for hand loading of bags only.

Hopper plate line 1 or hopper plate line 2 is low,

this error is generated as sign the hopper plate

door is not closed.

Close the hopper plate door.

If this message is displayed even with the hopper

plate door closed, please check the functionality

and alignment from the hopper plate door sensor.

12: ERROR CYC. START

SENSOR N1 L/H

An object is detected by the L/H start sensor (N1)

much longer than normal.

This can occur if a bin is not taken away from the

bin lift once it has been put down after a normal

emptying cycle.

If this message occurs with no bin or object in front

of the sensor or pedal arm please check the

sensor and cable.

13: ERROR POSITION

SENSOR L/H

This error can be generated by more than one

error and is a generally generated position sensor

error for the L/H lifting chair. When the bin is

removed the error will be reset.

Check for mechanical axial and radial play from

the position sensors or adjoined bearings.

Check the position sensor(s).

Check the cables from the position sensors.

Check the analogue values from the position

sensors (analogue input 00.0 and 00.1 always

higher than 100, lower than 900).

Recalibrate the position sensors.

Loading...

Loading...