3

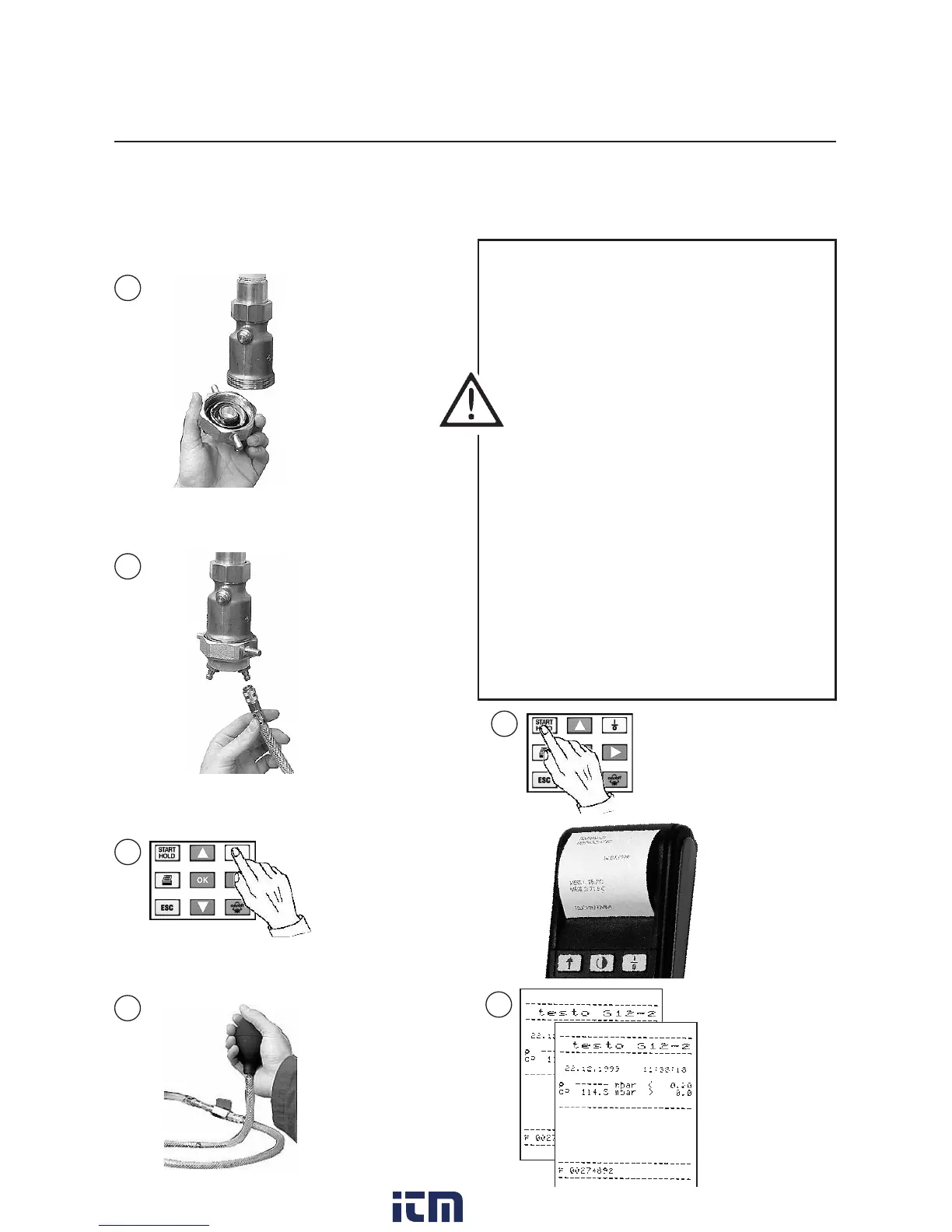

2

1

4

5

Insert single-

pipe counter

cap and

tighten.

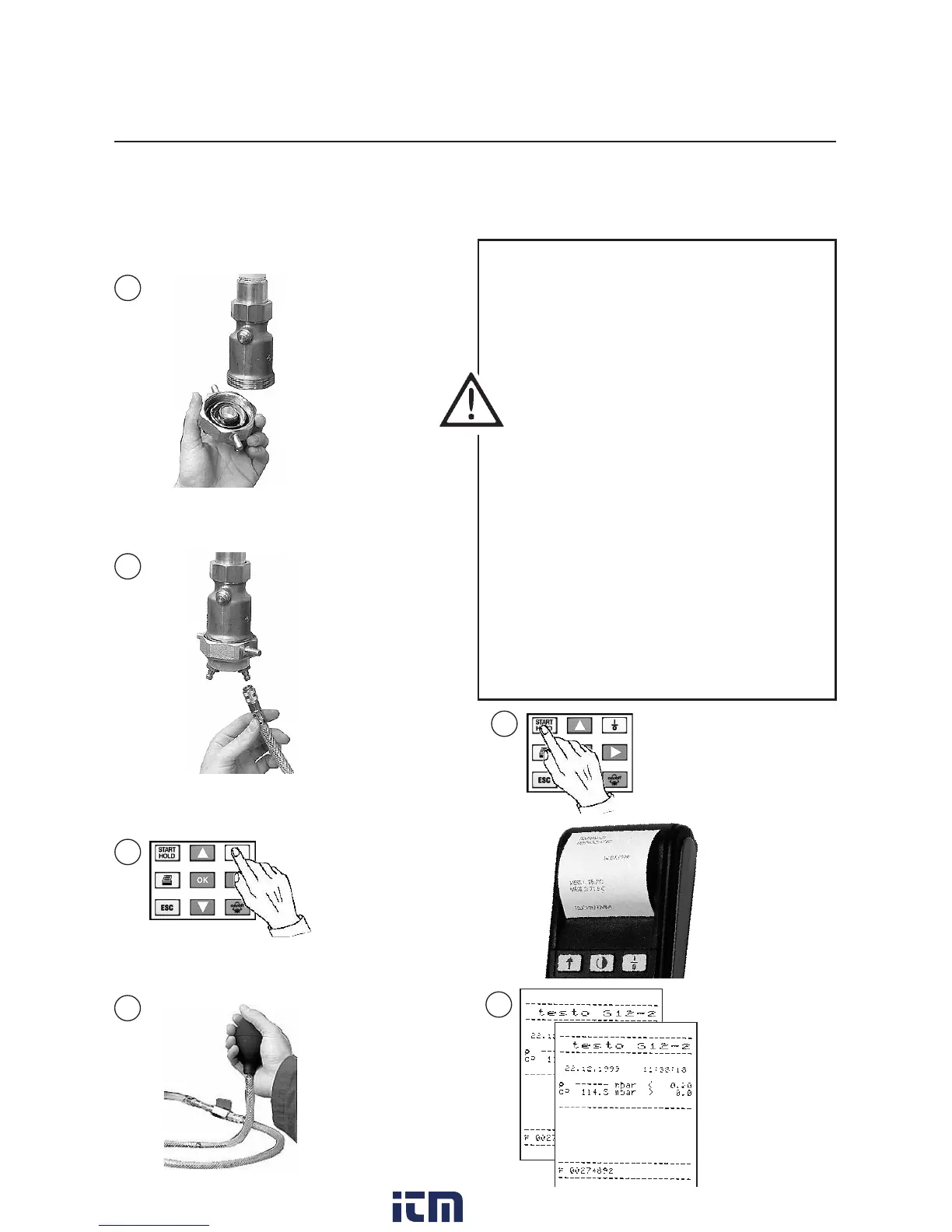

Example

Manual printout

triggers an

automatic

printout after 10

minutes.

6

Pre-test / Main test

Measurement example: testo 312-2/-3

10

Switch on

instrument.

Start measurement

with START/HOLD

button.

Ensure

connection is

correct.

Connect

pressure drop

set and

testo 312.

Compare

printouts

OK/not OK

Build up test

pressure

Carry out function test! Gas should not

get into the instrument when carrying

out measurements on gas pipes.

Pressure drop

The complete measuring system

(instrument, probe, hoses and connec-

tions) should be checked for a drop in

pressure e.g. using pressure drop test

set by attaching the single-valve stop.

Preliminary test

Pipes are checked, without fittings, with a

test pressure of 1 bar. This pressure should

not fall during the 10-minute duration of

the test.

Main test

Pipes are checked, with fittings, with a

test pressure of 110 mbar. This pressure

should not fall during the 10-minute

duration of the test. The measuring

instrument should be able to recognise

a drop in pressure of 0.1 mbar.

w ww . . co m

information@itm.com1.800.561.8187

Loading...

Loading...