5. Setting up Control Unit and analyser box measurement system

33

5.5 Assigning function keys

5.5.1 Function bar

·

Measurement menu is activated.

As required:

Use or to change display view so that the function button which is to be

assigned is visible.

1

Press , release and immediately press the function button to be assigned:

-

A selection list of the possible functions appears.

2

Select function and confirm with .

Reversing the assignment:

1

Press menu key , release menu key and then immediately press the defined

function key.

2

Select empty field with and confirm with .

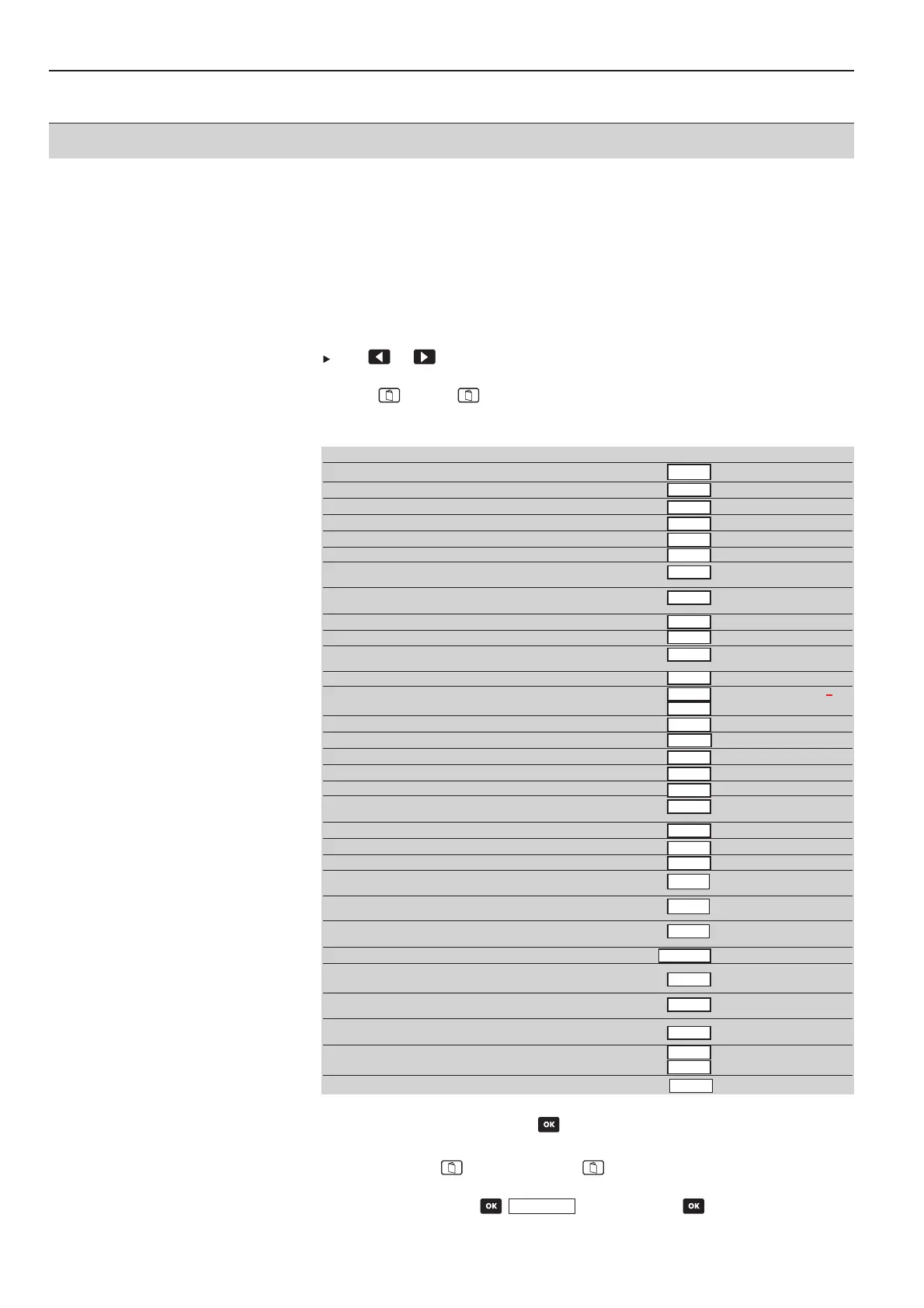

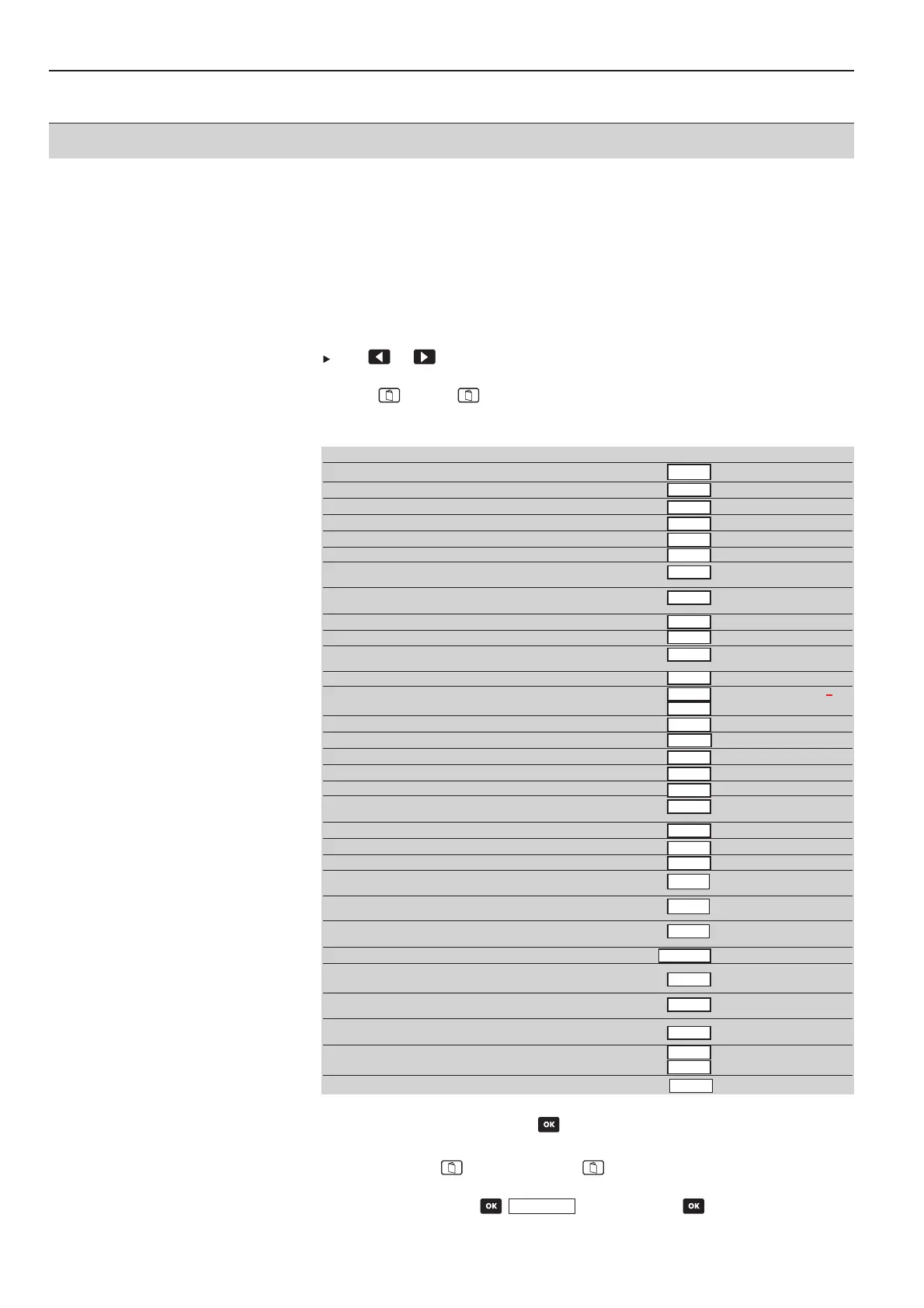

Function bar Control Unit analyser box

Free, non-assigned function button X

Zoom readings XX

Hold current reading X

Display max. values, since switch-on X

Display min. values, since switch-on X

Mean calculation X

Activate volume flow meas. (with a velocity or external X

differential pressure probe or internal pressure probe)

Activate/deactivate velocity measurement (with an external differential X

pressure probe or the internal pressure probe)

Measurement range 40 hPa for internal pressure sensor X

Measurement range 200 hPa for internal pressure sensor X

Zero pressure probe at user-defined probe socket (at least one X

differential pressure probe)

Zero the CO probe X

Start/stop measurement program X X

Determine system configuration X

Save readings XX

Print readings XX

Printer line feed XX

Turbulence calculation (with connected turbulence probe) X

Starts the measuring gas pump and indicates the readings on the display. When X

the function key P Start is clicked on, the function key changes to P Stop

The measuring gas pump stops, the readings are frozen at Hold X

Switches on and zeros velocity rate measurement with Pitot tube and pressure probe X

Manual storing of the current values under the displayed location names. X

Use of the two temperature inputs of the analyser box as separate X

2-channel temperature measurement with differential temperature display.

Activates the separate differential pressure measurement in the analyser box X

(draught measurement).The pump is stopped automatically once “d P” is activated.

Initiates the purging and zeroing phase (1 minute). The device draws fresh air X

through the measurement gas inlet or the fresh air valve (if fitted).

Manual change from measured gas to atmospheric air X

Manual deactivation of an activated CO sensor X

and purging with fresh air.

Manual activation of a deactivated CO sensor X

in the gas path.

Switching the dilution stage (digit in front of x corresponds to the set X

dilution factor)

Switching the HC module on/off X

X

Direct display of all error messages X

V OOn

Save

Delta TT

d PP

Null

COoff

COein

Gas ((air)

1 xx

HC OON

HC OOFF

DIAG

Max

Min

Mean

Vol

m/s

dP2

Pext=0

ppm=0

Start

Stop

Search

Save

Print

LF DDr

dP1

Turb

Zoom

Hold

P SStart

P SStop

Loading...

Loading...