THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

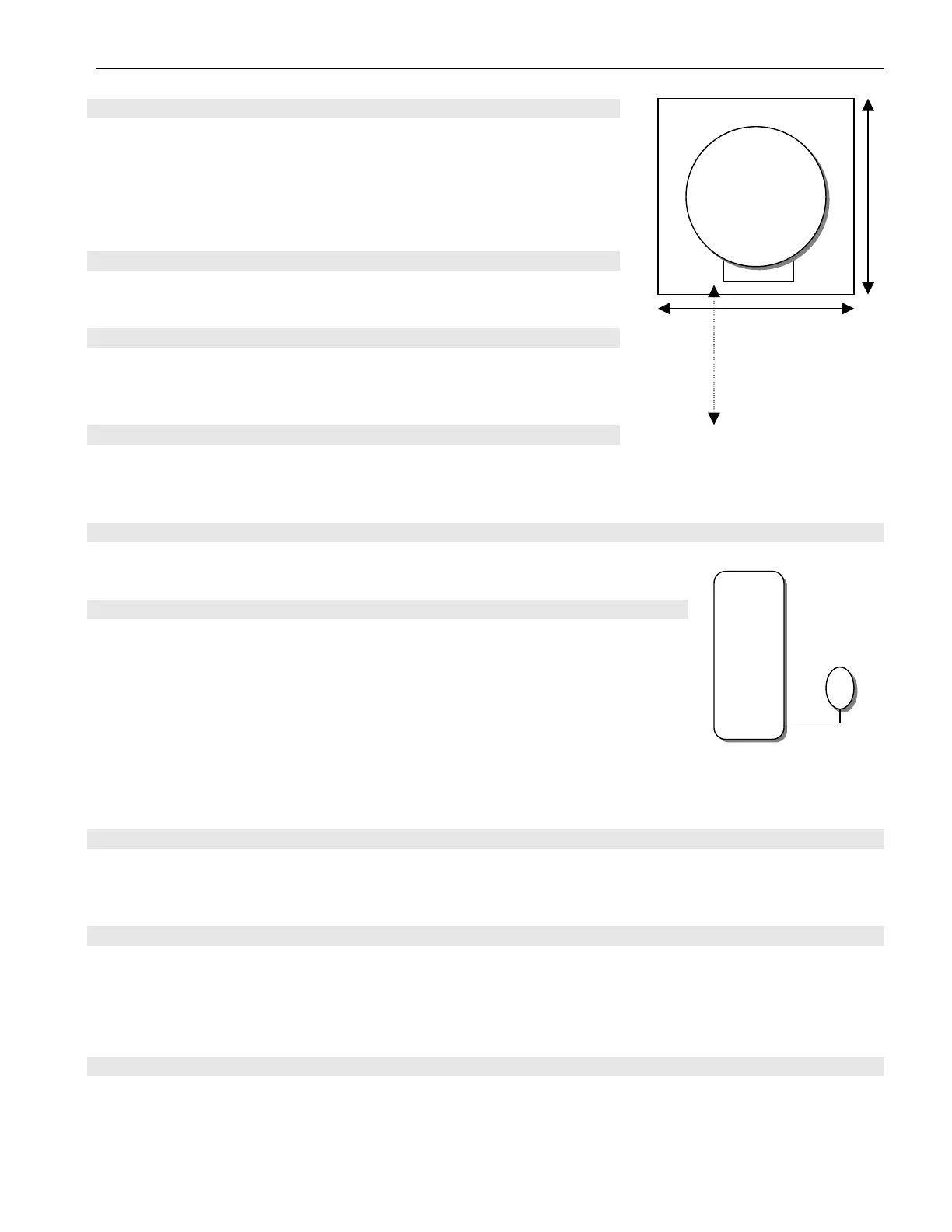

Diagram 2.2.3 - Clearances

2.2.3 Clearances

front

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see diagram

2.2.3 additional clearances may be required around the boiler for

installation. A clearance of 600mm is required at the front of the

boiler for maintenance and installation.

820mm

Thermaflow

Unit

2.3.1 General notes

The boiler is intended for use in a sealed system only.

750mm

2.3.2 Safety valve

600mm

The safety relief valve is an integral part of the boiler. It cannot

be adjusted but has a manual test device.

2.3.3 Pressure Gauge

A pressure gauge is incorporated into the boiler to indicate the system pressure.

The gauge has a cold fill set pointer.

2.3.4 Pump

14

The circulation pump is integral with the boiler.

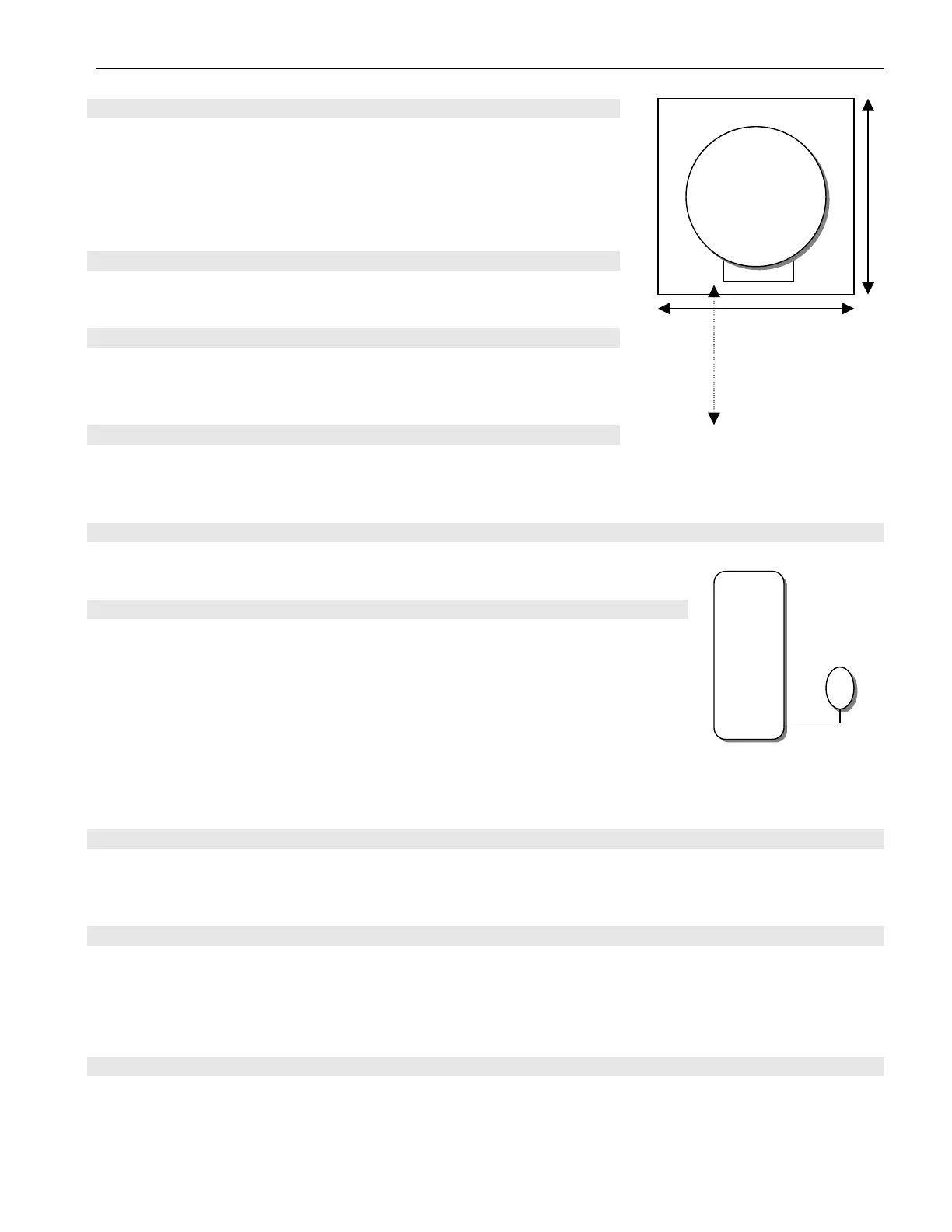

Diagram 2.3.5

2.3.5 Expansion vessel

Expansion

Vessel

The TH9/210U & TH12/210U and TH9/250 & TH12/250U are both supplied

with an expansion vessel with a capacity of 25 litres and the TH9/330U &

TH12/330U is supplied with a 35 litre expansion vessel. If the system water

content exceeds the maximum quoted in

table 1, [Data] an additional vessel

should be connected into the system as close as possible to the central

heating return connection of the boiler. Ref. Di

agram 2.3.5

Thermaflow ®

The charge pressure shall not be less than the static head at the point of connection, which is the

height of the top point of the system above the expansion vessel.

2.3.6 By- pass

An automatic by- pass valve should be incorporated in the system for maximum system

efficiency. (A By-Pass MUST be fitted on all models).

2.3.7 Filling sealed systems

The boiler has a filling loop incorporated within it, and pressure gauge to register the fill pressure.

There must be no permanent connection to the mains water supply; even though a non return valve is

supplied.

Disconnect filling loop and seal both valves with suitable caps.

2.3.8 Corrosion inhibitor

The maintenance of sufficient concentration of corrosion inhibitor in your Thermaflow system is vital to

prevent corrosion. We would recommend sentinel X100, or equivalent. Dose appropriately according to

the size of the Thermaflow and central heating system volume combined.

Loading...

Loading...