SERVICE 5-2 Manual 0-2724

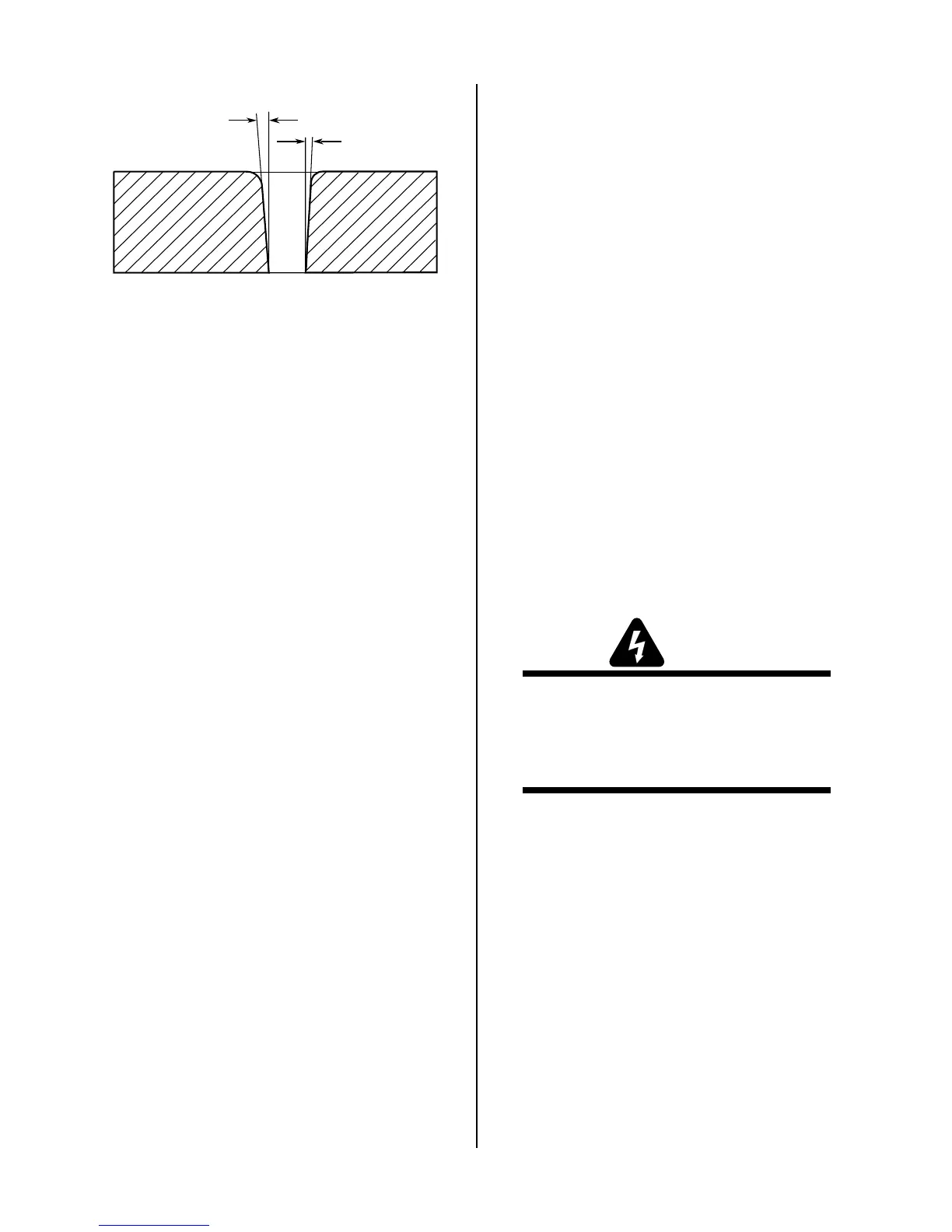

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Figure 5-1 Side Characteristics Of Cut

E. Dross

Generally when dross is present on carbon steel, it is called

either "high speed or slow speed dross".

"High speed dross" usually forms a narrow bead along

the bottom of the cut edge and is very difficult to remove.

"Slow speed dross" will be in larger quantities but does

not adhere tightly to the cut edge and can be removed

easily.

When cutting a troublesome steel, it is suggested that the

torch travel speed be reduced to produce "slow speed

dross". Any required cleanup can then be done by scrap-

ping, not grinding.

Dross present on top of the plate (top spatter), is normally

caused by a slow torch travel speed or too high of a torch

standoff distance.

F. Common Cutting Faults

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non-genuine Thermal Dynamics parts used.

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non-genuine Thermal Dynamics parts used.

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

3. Non-genuine Thermal Dynamics parts used.

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect pressure)

e. Improperly assembled torch

f. Non-genuine Thermal Dynamics parts used.

5.04 Troubleshooting Guide

A. General

Troubleshooting and repairing this unit should be un-

dertaken only by those familiar with high voltage high

power electronic equipment.

WARNING

There are extremely dangerous voltage and power

levels present inside this unit. Do not attempt to

diagnose or repair unless you have had training in

power electronics measurement and troubleshoot-

ing techniques.

B. Basic Troubleshooting

This manual covers a basic level of troubleshooting that

requires limited disassembly and measurements. It is

helpful for solving many of the common problems that

can arise with this system.

If major complex subassemblies are faulty, the unit must

be returned to an authorized service center for repair.

Follow all instructions as listed and complete each sec-

tion in the order presented.

For major troubleshooting and parts replacement pro-

cedures refer to CutMaster 80XL Power Supply (CE)

Service Manual 0-2725.

Loading...

Loading...