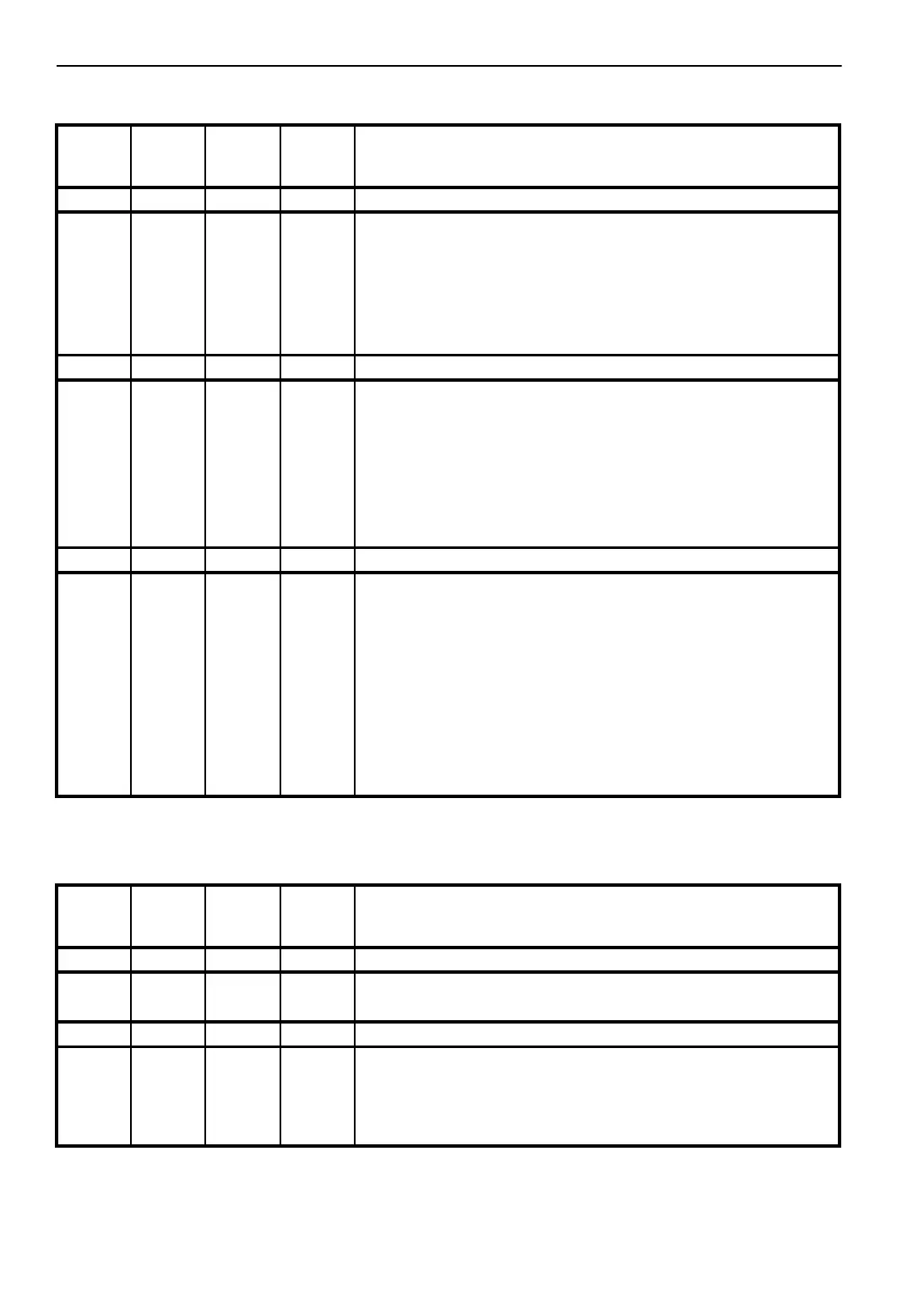

Maintenance Inspection Schedule

18

Electrical

•••Inspect battery terminals and electrolyte level.

•••Inspect wire harness for damaged wires or connections.

••••Check operation of damper door (closes on defrost initiation and

opens on defrost termination).

• Inspect alternator wire connections for tightness.

— Inspect electric motor, replace bearings yearly or every 6,000 hours.

Refrigeration

••••Check refrigerant level.

•••Check for proper suction pressure.

•••Check throttling valve regulating pressure.

• Check compressor oil level and condition.

• Check compressor efficiency and pump down refrigeration system.

— Replace dehydrator and check discharge and suction pressure every

two (2) years.

Structural

••••Visually inspect unit for fluid leaks.

••••Visually inspect unit for damaged, loose or broken parts (includes air

ducts and bulkheads).

•••Inspect tapered roller bearing fanshaft and idlers for leakage and

bearing wear (noise).

•••Clean entire unit including condenser and evaporator coils and

defrost drains.

•••Check all unit and fuel tank mounting bolts, brackets, lines, hoses,

etc.

•••Check evaporator damper door adjustment and operation.

Host Unit (Continued)

Pretrip

Every

1,500

Hours

Every

3,000

Hours*

Annual/

4,500

Hours

Inspect/Service These Items

* 3,000 hours or two years, whichever occurs first.

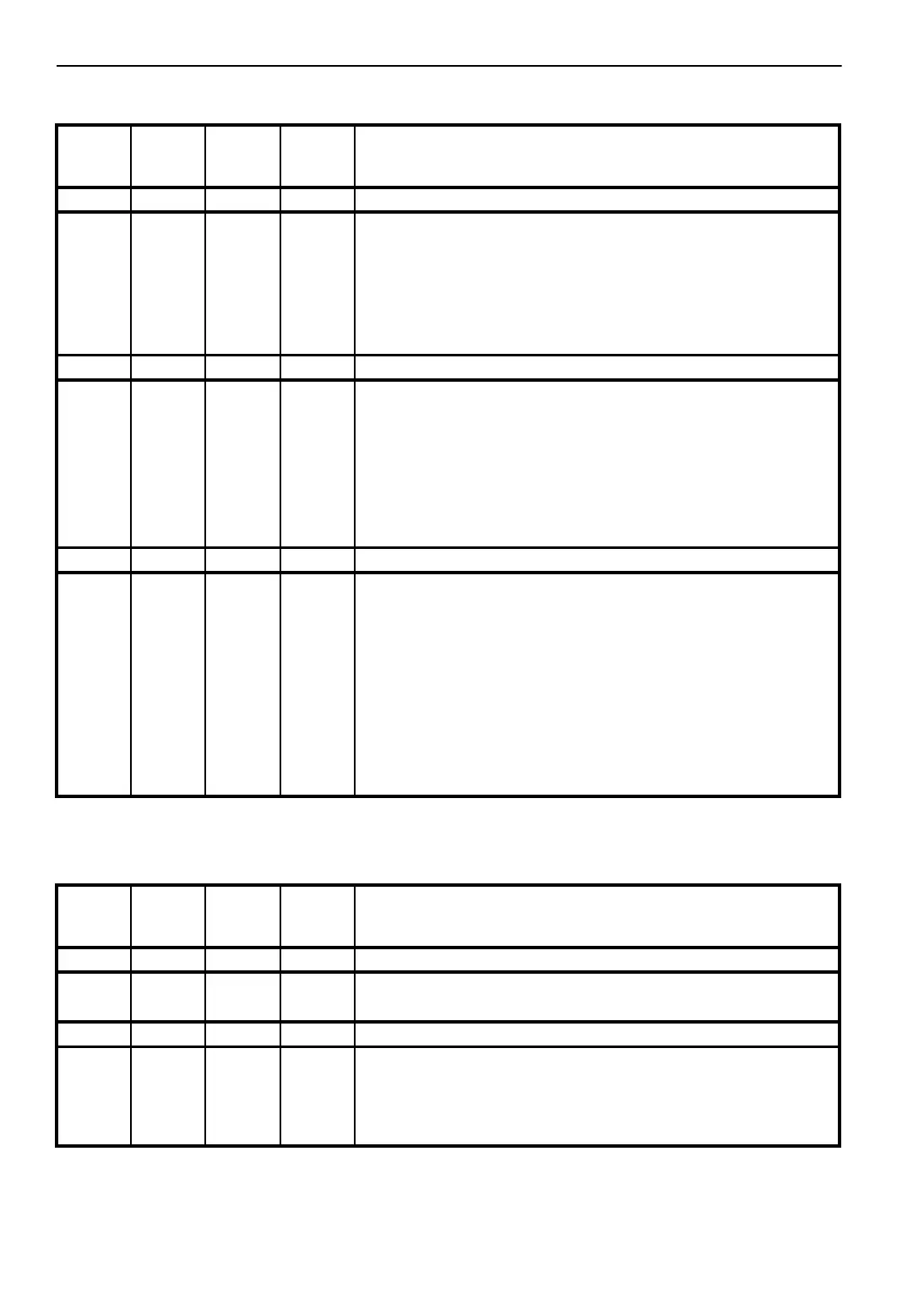

Remote Evaporator(s)

Pretrip

Every

1,500

Hours

Every

3,000

Hours*

Annual/

4,500

Hours

Inspect/Service These Items

Electrical

•••Inspect wire harness for damaged wires or connections.

•••Inspect/replace DC fan motors.

Structural

••••Visually inspect unit for fluid leaks.

••••Visually inspect unit for damaged, loose, or broken parts.

•••Clean entire unit including evaporator coils and defrost drains.

• Check all unit mounting bolts, brackets, lines, hoses, etc.

Loading...

Loading...