Form RZ-NA-I-TR, Page 6

9. Prepare and Install Burner/Control Box and Combustion Chamber

Tube

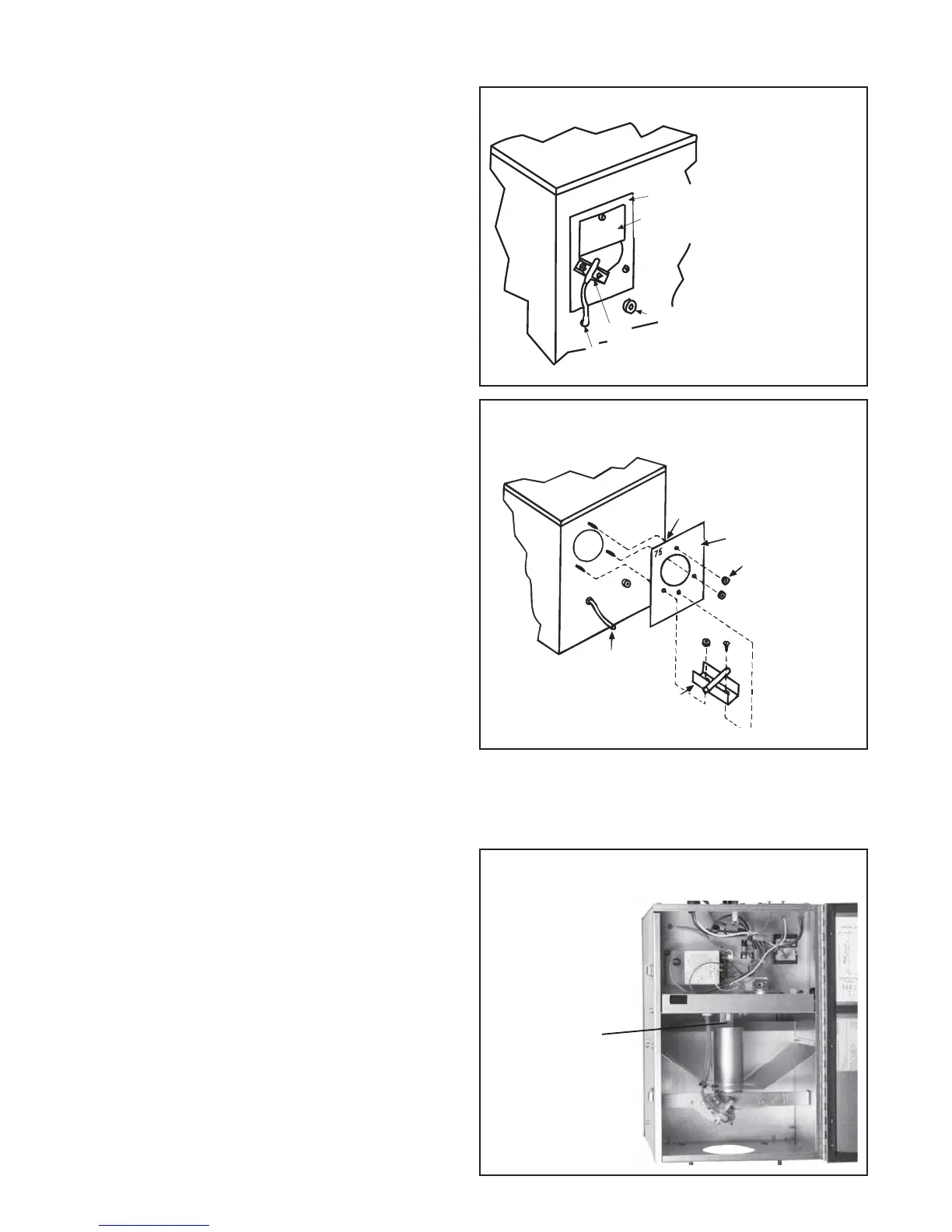

Figure 3A - Combustion Air Inlet Side of

Burner/Control Box

Figure 3B - Remove factory-installed air restrictor plate

and replace with the restrictor plate in the parts bag

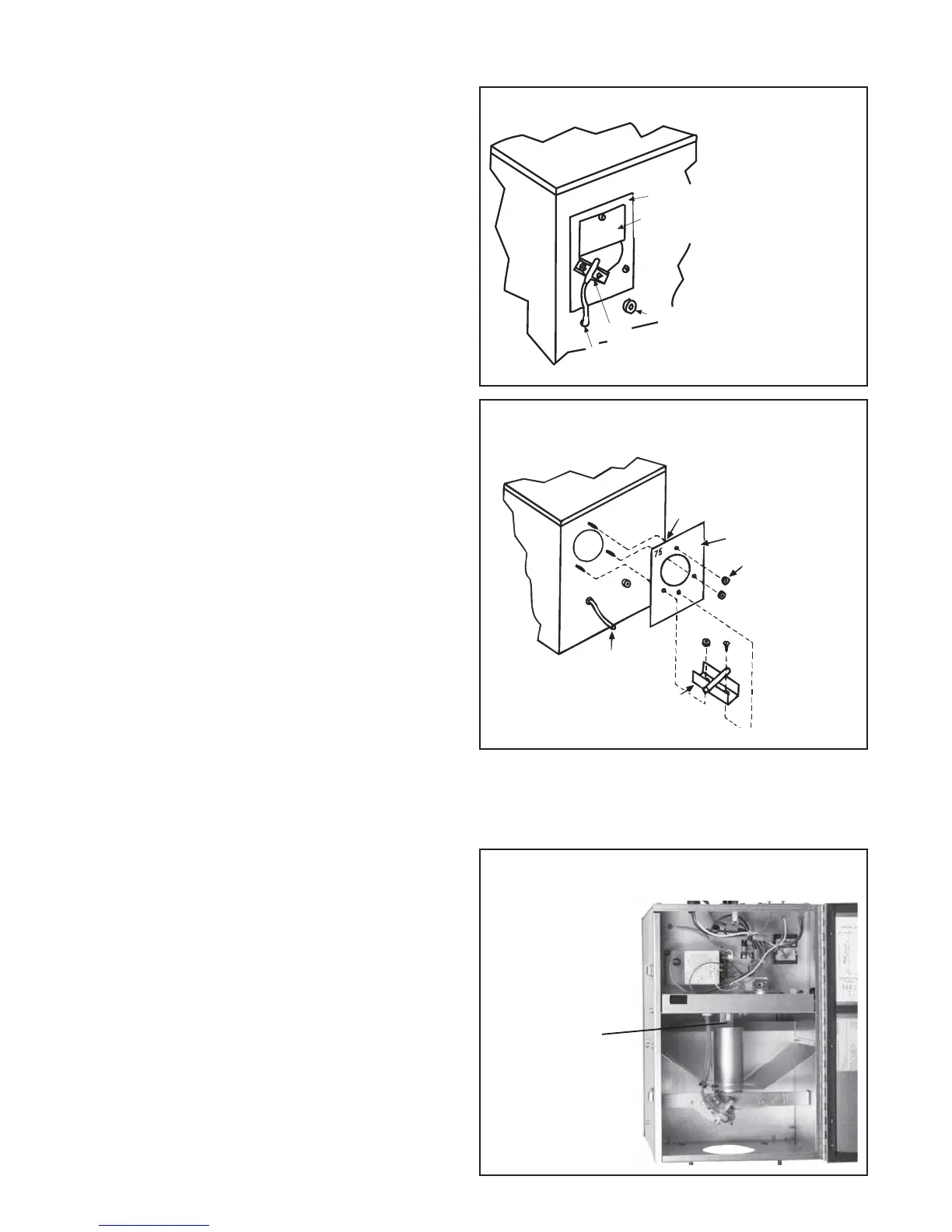

Figure 4 - Burner/Control Box Showing Location of

the Burner Orifice

Burner Orifice

-- Remove with

9/16" open end

wrench

Model Size is stamped

in the upper left hand corner

Combustion Air

Restrictor Plate

10-32 Nuts

Rubber tubing (attaches to

combustion airflow sensor)

Combustion Airflow Sensor

There are very important steps that must be followed to prepare, sus-

pend, and assemble these tubular radiant heaters. Preparing the heater,

suspension, and field assembly are the responsibility of the installer.

Follow all instructions carefully.

STEP 1) Prepare Burner/Control Box

All burner/control boxes require some field preparation. The type of

preparation depends on how the unit was ordered and where it will be

installed. Determine which of these six situations matches your applica-

tion and follow the appropriate instructions. The first three are for units

ordered by specific size; the last three are for burner/control box pack-

ages that cover two sizes. (Refer to Paragraph 6 for further explanation

on packaging.)

• The unit was ordered as a specific size to be installed at a specific

elevation (sea level or high altitude) and is being installed at

that elevation. Proceed to STEP 2 of these Preparation instructions.

• The unit was ordered as a specific size to be installed at sea level

to 2000 ft and is being installed above 2000 ft (NOTE: Does not

apply to Sizes 125 and 150). Install the high altitude kit selected in

Paragraph 7. Follow the instructions provided with the kit. When the

kit is installed, proceed to STEP 2 of these Preparation Instructions.

• The unit was ordered as a specific size to be installed at an

elevation above 2000 ft and is being installed at a different eleva-

tion above 2000 ft. Install the high altitude kit selected in Paragraph

7. Follow the instructions provided with the kit. When the kit is

installed, proceed to STEP 2 of these Preparation Instructions.

• The burner/control box was ordered as a TR75/100, TR125/

150, or TR175/200 and will be installed at sea level to 2000 ft as

a Size 75, 125, or 175. Proceed to STEP 2 of these Preparation

instructions. (The Size Conversion Kit shipped with the burner/con-

trol box will not be used.)

• The burner/control box was ordered as a TR75/100 or TR175/

200 and will be installed above 2000 ft elevation as a Size 75, 100,

175, or 200. Install the high altitude kit selected in Paragraph 7.

Follow the instructions provided with the kit. When the kit is in-

stalled, proceed to STEP 2 of these Preparation Instructions. (The

Size Conversion Kit shipped with the burner/control box will not be

used.)

• The burner/control box was ordered as a TR75/100, TR125/

150, or TR 175/200 and will be installed at sea level to 2000 ft

elevation as a Size 100, 150, or 200. Follow the instructions below

to install the size conversion kit shipped with the burner/control box.

Instructions to Change the Combustion Air Restrictor Plate and

Burner Orifice to Field Convert a Burner/Control Box from Size

75,000 to 100,000; or from Size 125,000 to 150,000; or from Size

175,000 to 200,000.

Parts Required: Conversion package in the burner/control box includ-

ing a burner orifice, a combustion air restrictor plate, and conversion

labels.

1. Conversion Size Labels (one on the restrictor plate, one or two

loose) -- Fill-in all labels stating that the burner/control box has been

converted to either a Size 100,000, 150,000 or 200,000.

2. Change Air Restrictor Plate -- Refer to Figure 3A and identify the

combustion air inlet on the side of the burner box. Locate the paper

warning label on the factory-installed combustion air restrictor plate.

Attached to the restrictor plate is a combustion air sensor tube and

bracket. See Figure 3B.

Remove the hardware (screws and/or nuts) holding the combustion

air sensor bracket and the restrictor plate. Remove and discard the

factory-installed combustion air restrictor plate. Using the same hard-

ware, attach the combustion air restrictor plate shipped in the parts

bag. Re-attach the combustion air flow sensor bracket.

3. Change Burner Orifice - Open the hinged access panel on the

bottom of the burner/control box. Locate the burner orifice. See Fig-

ure 4. Using a 9/16" open-end wrench, remove and discard the fac-

tory-installed burner orifice. Install the burner orifice shipped in the

parts bag. Close the bottom panel.

Combustion Air Restrictor Plate

Warning label which

must be removed

Static Pressure Port

Combustion Airflow Sensor

Tubing to Pressure Switch

IMPORTANT

Loading...

Loading...