38

4.2 Chuck preparation

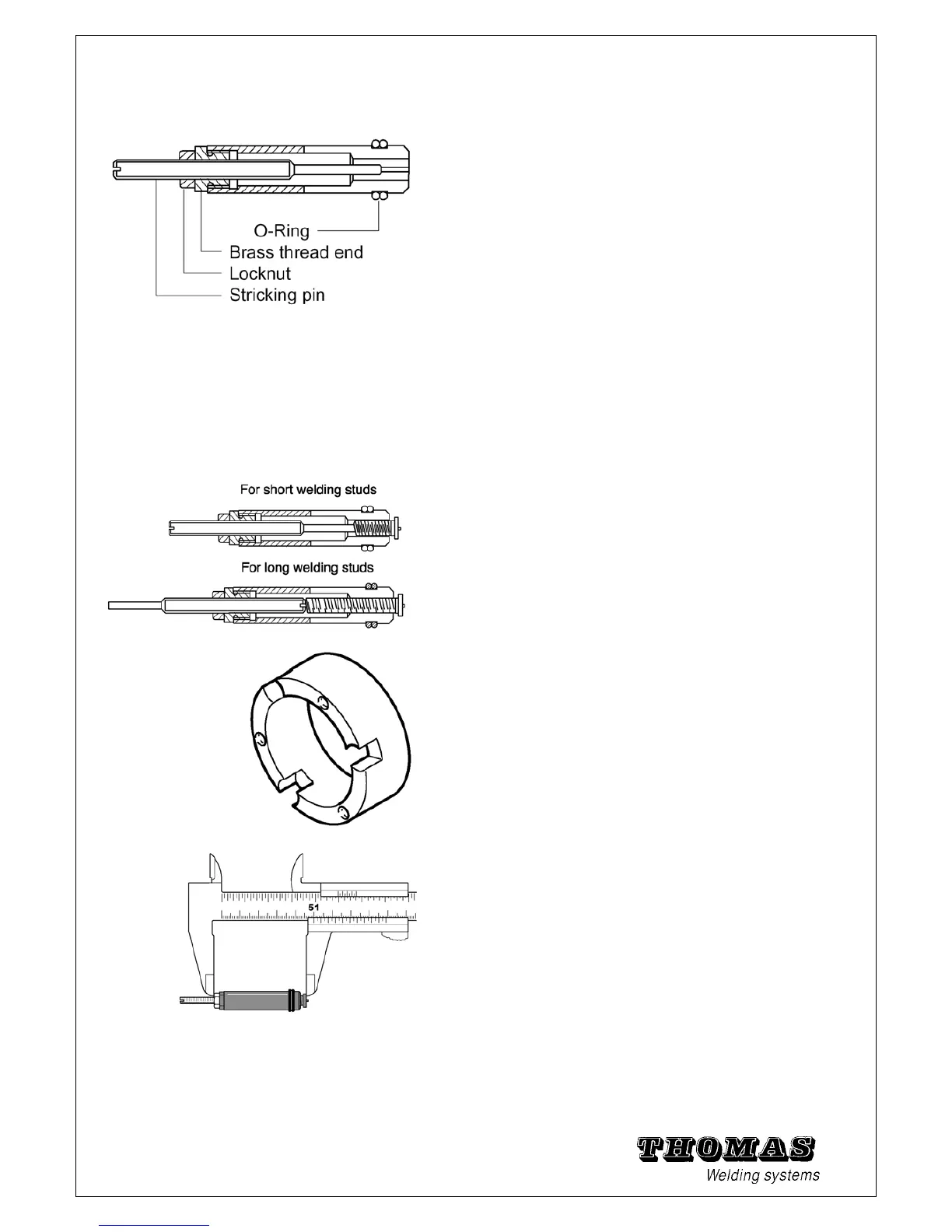

The Chuck is selected in dependence on the welding

element

(welding stud). The extent of delivery of the stud welding

system

contains chucks from M3 to M8.

The suitable Chuck must then be adjusted to the length of

the

welding element

.

Note: Chucksare wearing parts and should therefore

always be

kept in stock and ordered in time (see chapter 5.10).

Procedure

1. Select a Chuck fitting the diameter and form of the

welding element.

2. Depending on the length of the welding element, fit the

striking

pin in the Chuck as follows:

a) Welding elements up to 20 mm in length:

The unthreaded part of the striking pin is located

inside the chuck.

b) Welding elements from 20 to 40 mm in length:

The unthreaded part of the striking pin is located

outside the chuck.

c) Welding elements over 40 mm in length:

An intermediate ring (accessory part) is additionally

required (see

chapter 1.19 and chapter 5.4).

3. Equip the Chuck with the welding element.

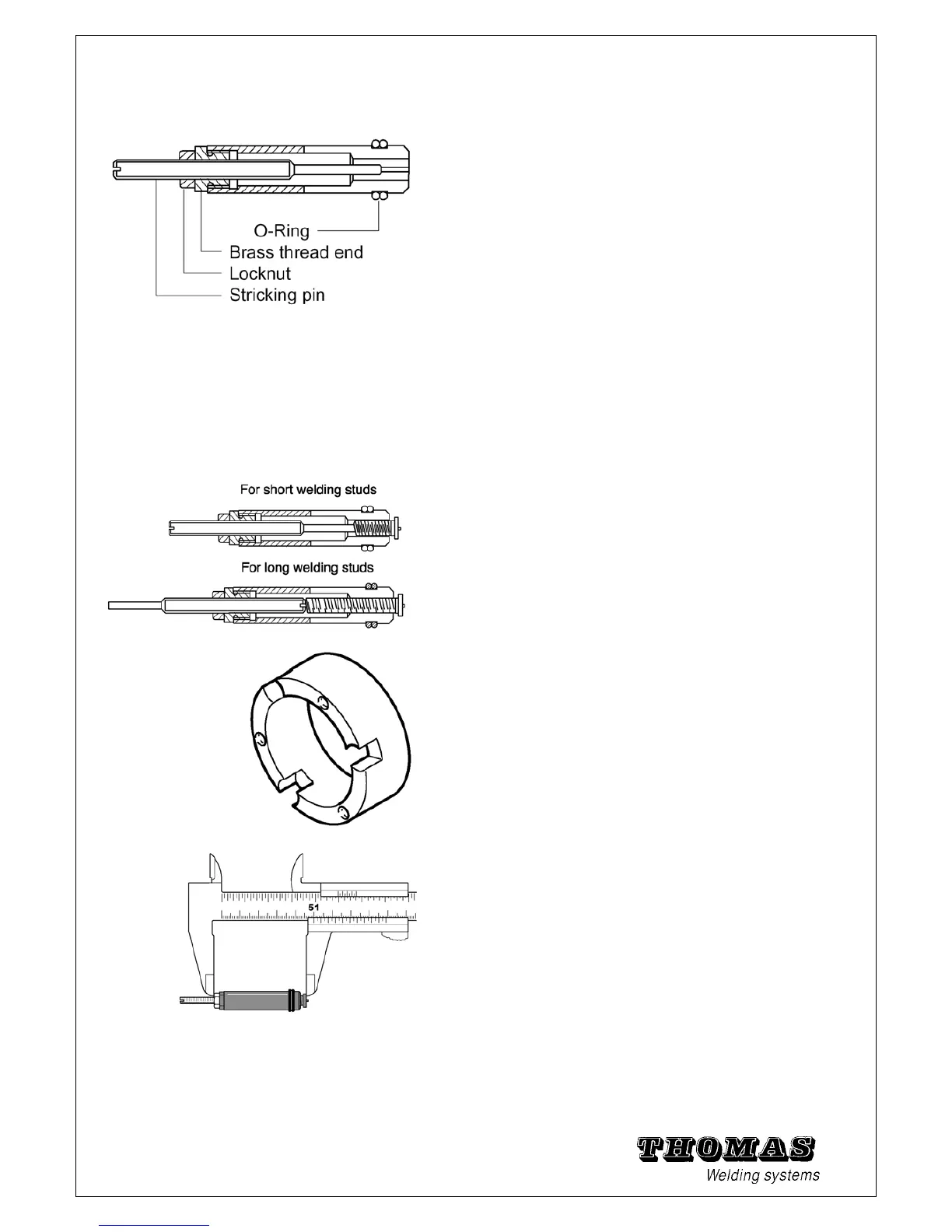

4. Turn the striking pin until the distance between locknut

and stud face is:

when using the C0: 51 mm (to max. 53 mm)

.

Note: Add 12.5 mm when using a Chuck extension!

5. Warning: Switch off the power unit before inserting the

Chuck (to rule out any eventualities).

Loading...

Loading...