45

4.7 Testing the weld

Testing of the weld in continuous production monitoring is

restricted to a visual inspection of the welded stud. Further

testing is possible, but complex. Consult your TWS specialist

advisor or study DVS Guideline*) 0905 Part 2 in this regard.

If a weld is thought to be defective, an impact bending test

must be carried out on the welding studs concerned according

to section 4.7.2.

*) DVS Guideline 0905 Part 2: Ensuring the quality of stud welds "Stud

welding with tip ignition"

**) DIN 8563 Part 10: Ensuring the quality of stud welds (edition:

December 1984)

4.7.1 Visual inspection

Every welded welding element must be checked visually.

Besides

assessing the weld bead for form, size and appearance, you

should also check the nominal length of the welded stud.

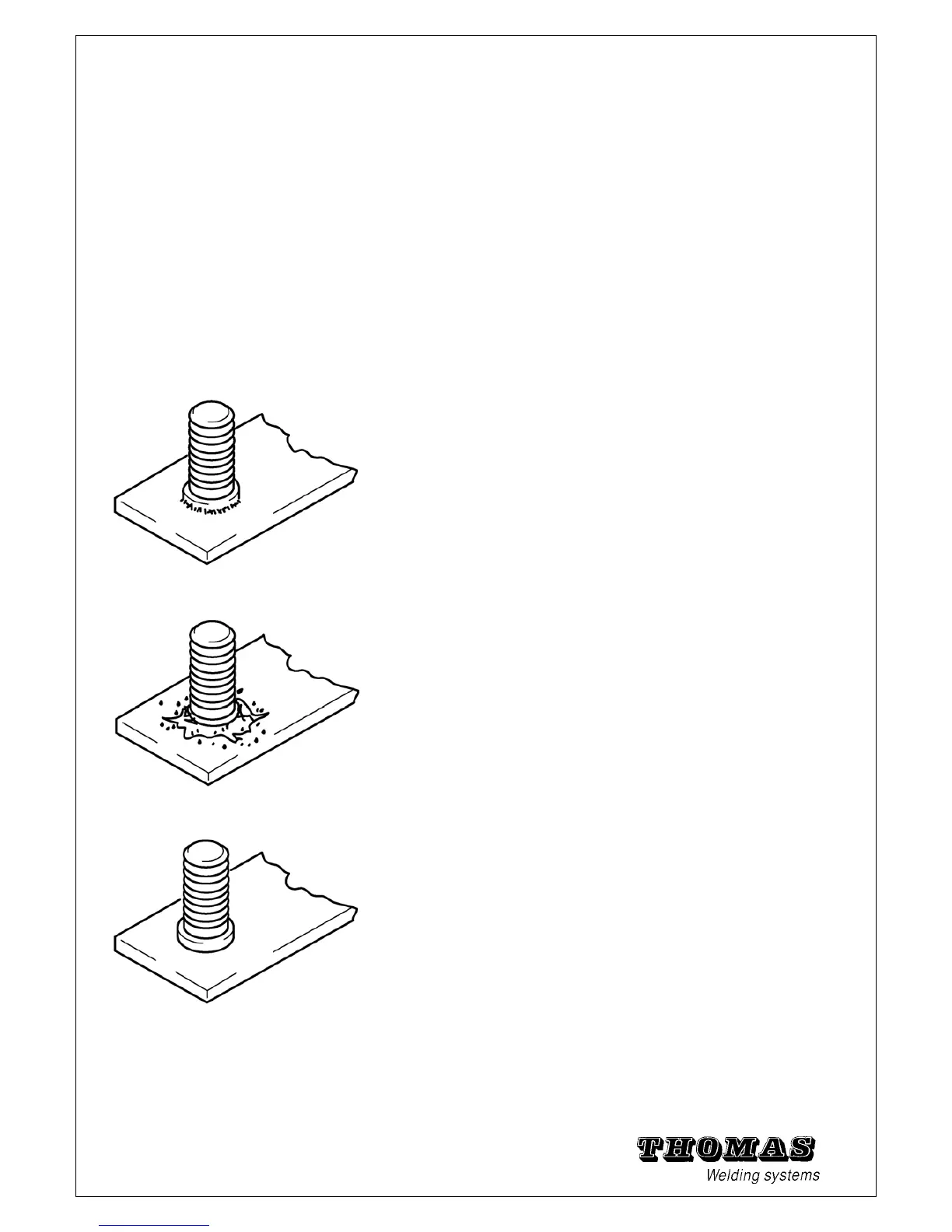

1. Good welding:

The bead is closed and has a shiny surface. There is no visible

undercutting at the bottom of the welding element. Small

notches

between weld bead and stud shaft are unavoidable and can be

ignored.

2. Welding too hot:

Deep notches can be seen between weld bead and stud shaft.

Due to the strong melting, the melt zone at the stud middle is

recessed.

The excess weld metal was flung out of the welding zone.

(Spring force or lift too low.)

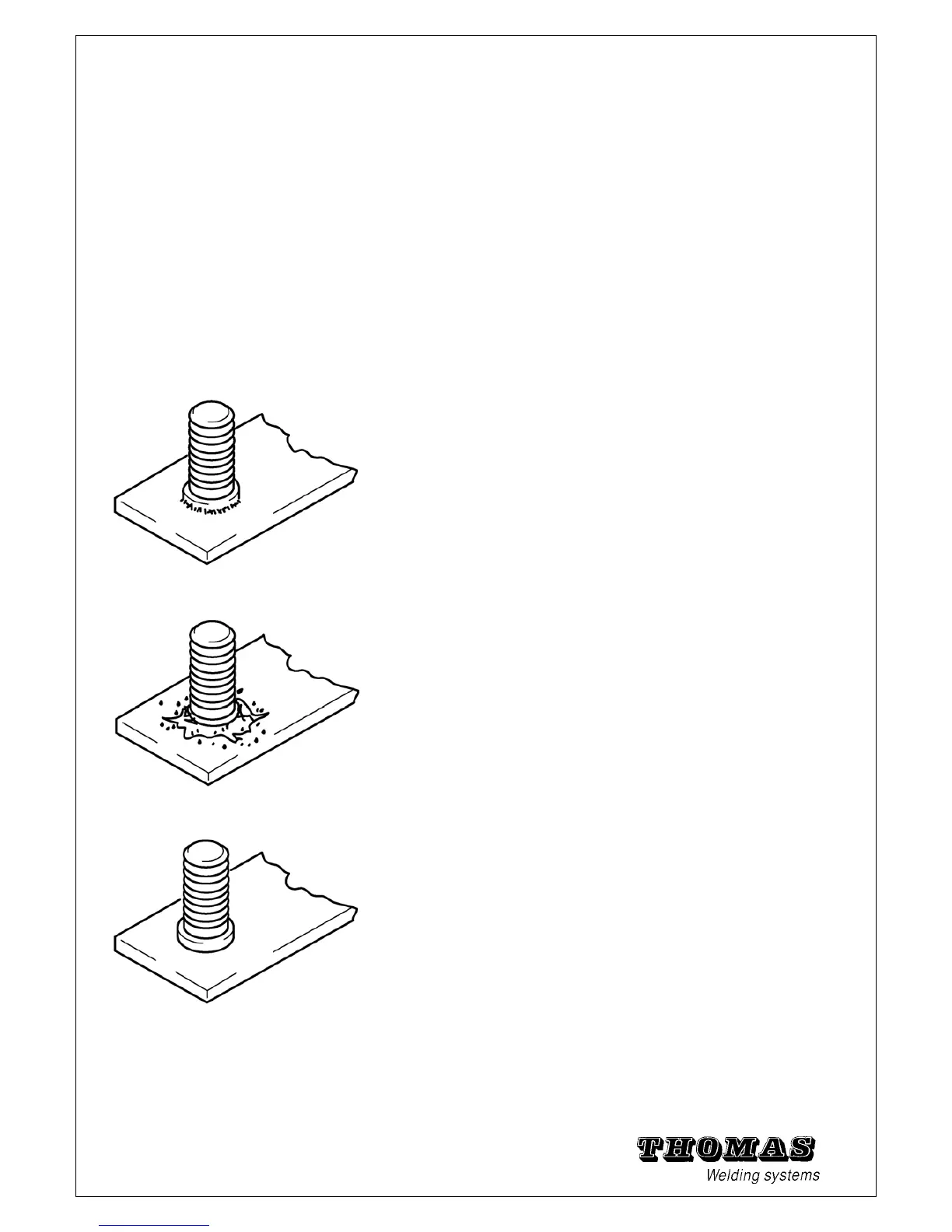

3. Welding too cold:

The form and height of the weld bead are irregular. Distinct

undercutting

can be seen at the stud edge. Due to the low energy, the

melt zone under the complete stud cross-section is very flat.

(Spring force or lift too high.)

Loading...

Loading...