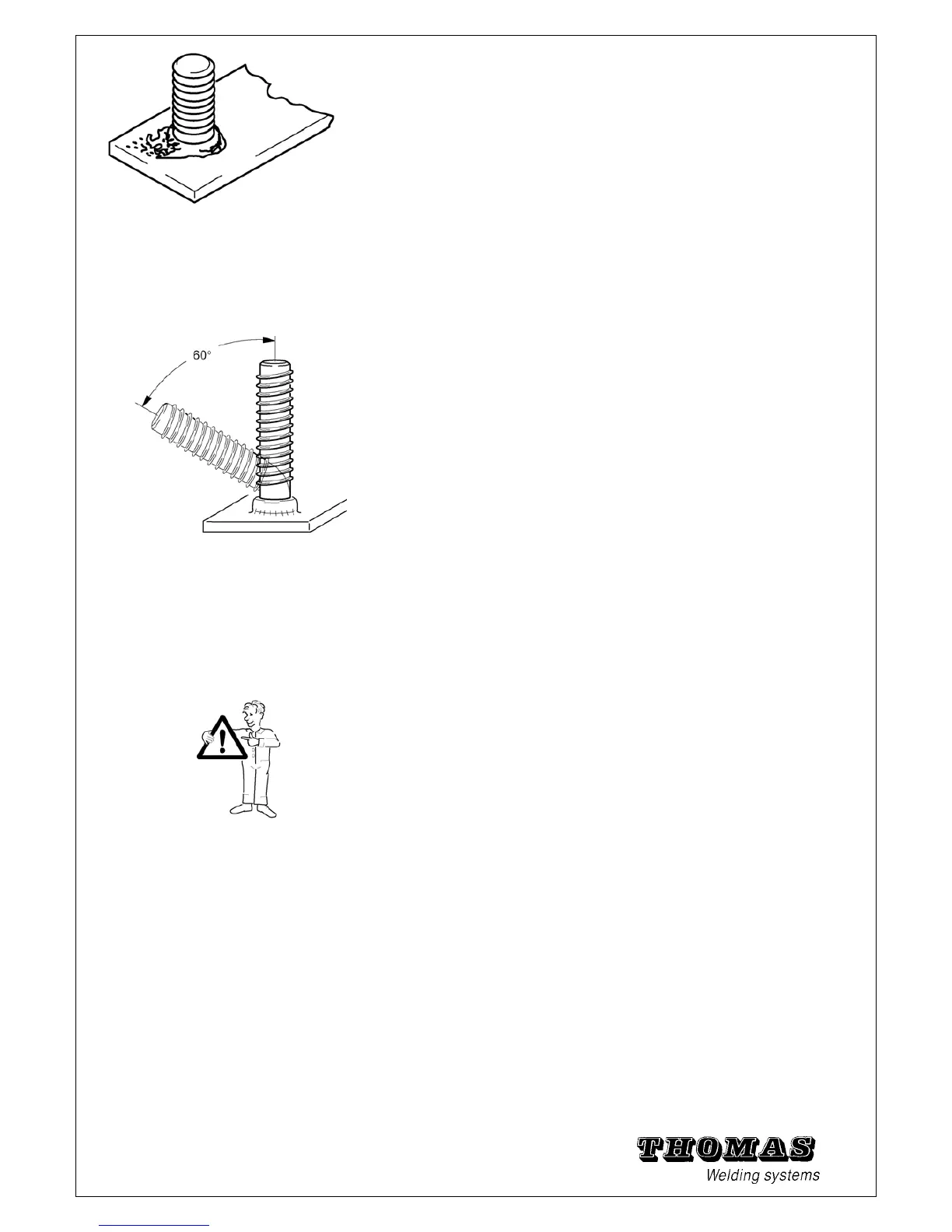

4. Welding too irregular:

The weld bead is asymmetrical (as a result of magnetic arc

blowing

action) and the stud edge is undercut on one side. (Possibly

change earth clip positions.)

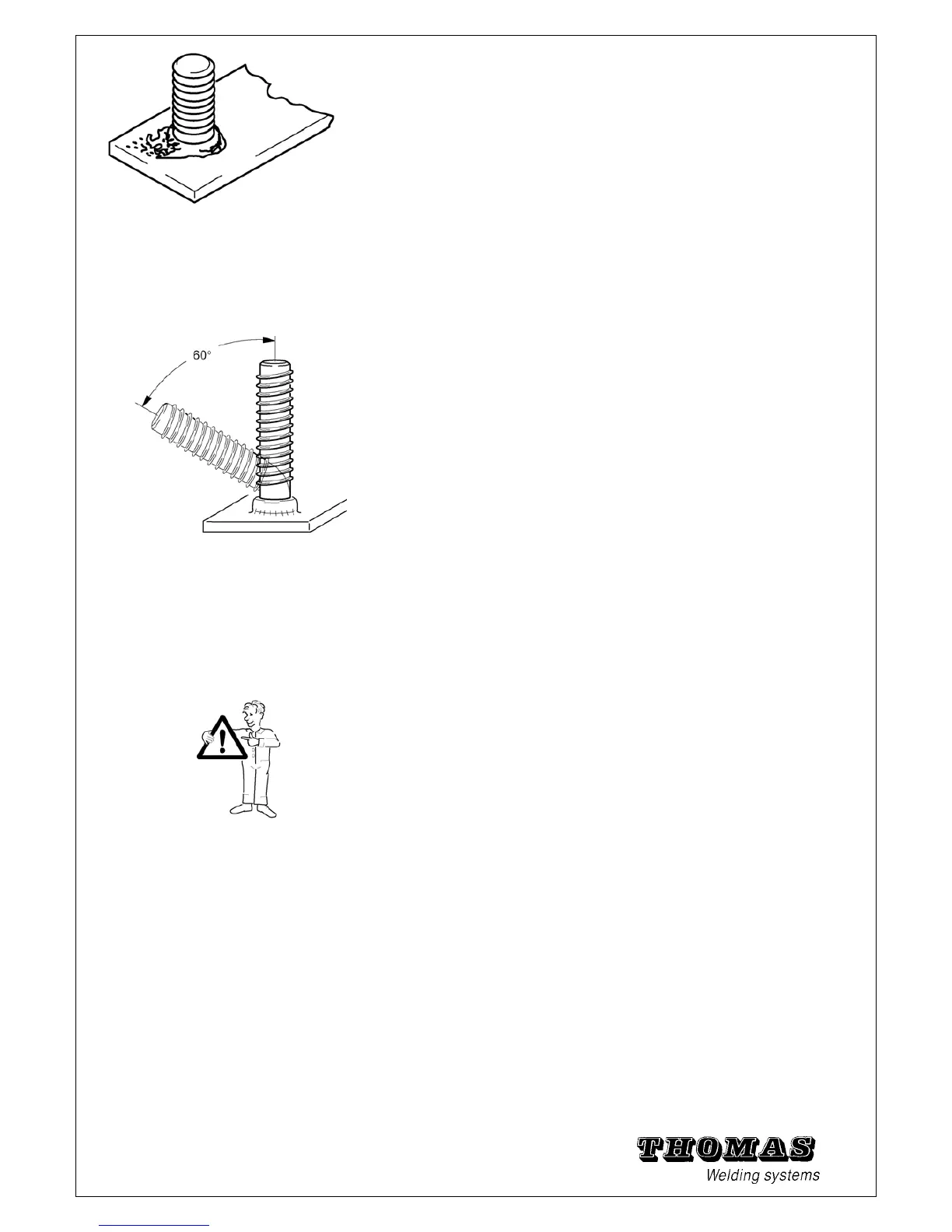

4.7.2 Impact bending test

The impact bending test is one of the most common test methods

to check welding parameters and to identify defective welds.

If a weld joint is thought to be defective or the fusion length of the

stud is too short, the impact bending test must be carried out as follows:

Bend the welding element by 60° with a hammer or bending device.

This stresses the weld joint in tension, pressure and bending

by an undefined amount.

• The impact bending test is deemed as passed if there are no

cracks to be seen in the welding zone.

• If the welding element is torn out of the base metal (a recess is

formed in the workpiece), the weldability of the materials is

deemed proven.

• If the welding element breaks off in the welding zone, you must

check whether:

- both materials are weldable,

- the material combinations are weldable,

- the ignition tip is in order,

- the settings on the welding gun and power unit are correct and

the welding gun or power unit is defective.

-

If these requirements are not met, an impact bending test must

also be carried out on the three previous and three next welds.

Warning:

Welding work may only be continued when satisfactory

test results are obtained.

46

Loading...

Loading...