OPERATING MANUAL 6. SERVICING

ThyssenKrupp Aufzugswerke GmbH 42 Issue 06.2004

6.1 Servicing of DAF270

Servicing interval: servicing of the machine should be carried out at least

once a year, preferably in the course of the general elevator servicing.

Note: installation and servicing works shall only be carried out by trained and

qualified personnel.

These persons must know and observe the respective regulations and

requirements for elevator installations as well as the accident prevention

regulations.

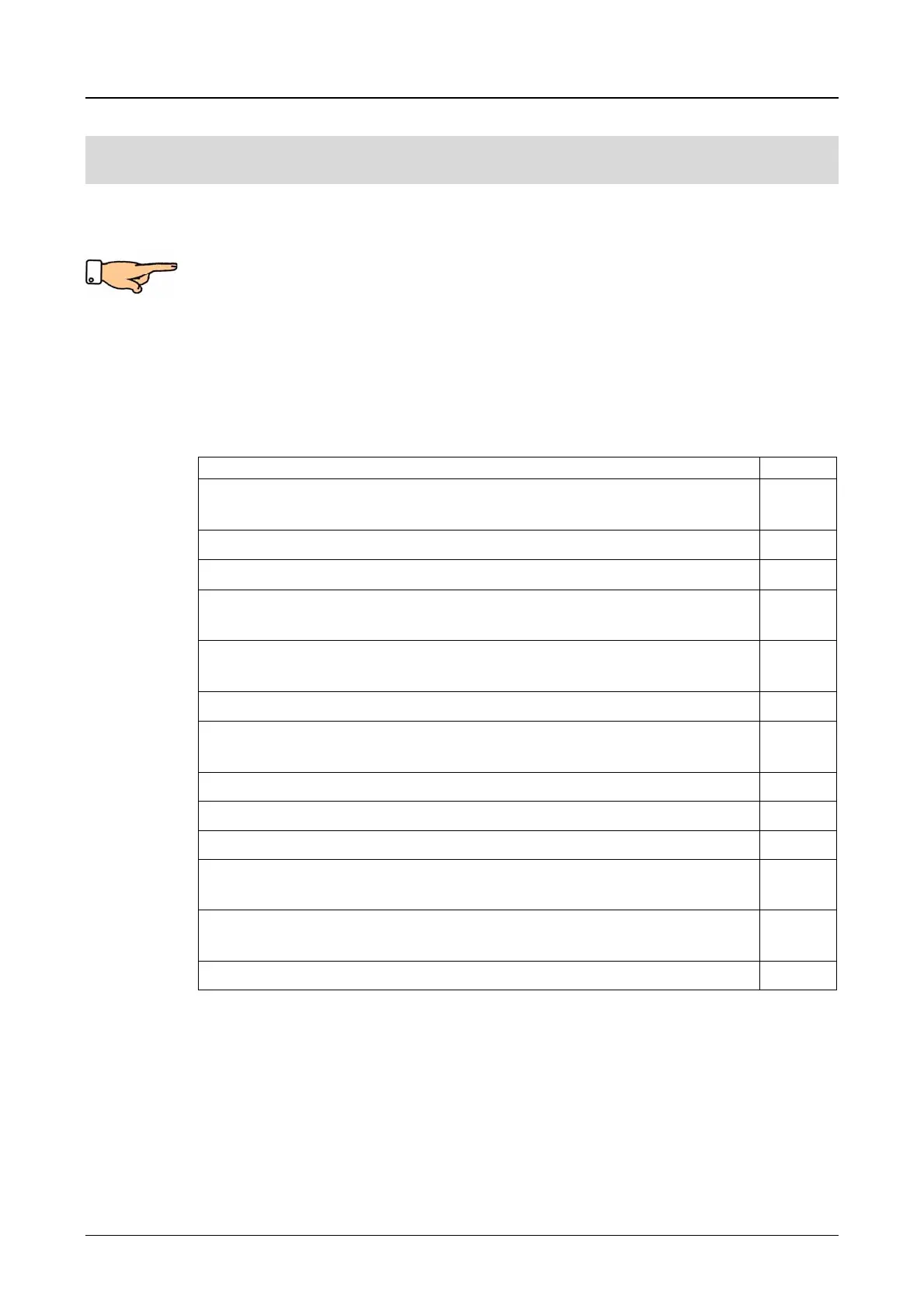

Further information concerning proceeding, adjustment and data see

chapters:

Ø

• Check armature base plate - air gap between armature disc

and brake coil body for wear of brakes

6.2

• Check brake deceleration

6.2

• Check brake control switches for proper functioning

7.3

• Check screw-connections and fastenings for proper

tightening (tightening torque)

8.1

• Check grooves of traction sheave and drive fastening for

proper tightening; re-tighten, if required.

7.4

• Check groove profiles for damage and wear

• Check electrical connections for correct working, sound

condition and proper fastening

• Check motor bearings for wear (noise, backlash)

• Check protective and safety equipment; test for

correct working

• Check protective and safety equipment; check danger and

instruction signs; check signs for proper affixing and visibility

Loading...

Loading...