TW 160PH

SERVICE INSTRUCTIONS

14 / 51

C190-0013 11.04.2019

NOTE: Your Timberwolf woodchipper is covered by a full 12 months parts and labour warranty. Subject to

correct maintenance and proper machine usage, the bearings are guaranteed for 12 months regardless of hours

worked by the machine. In conditions of 'heavy usage' - i.e. in excess of 500 hours per year - it is recommended

that the bearings are changed annually to ensure that the machine retains optimum working performance.

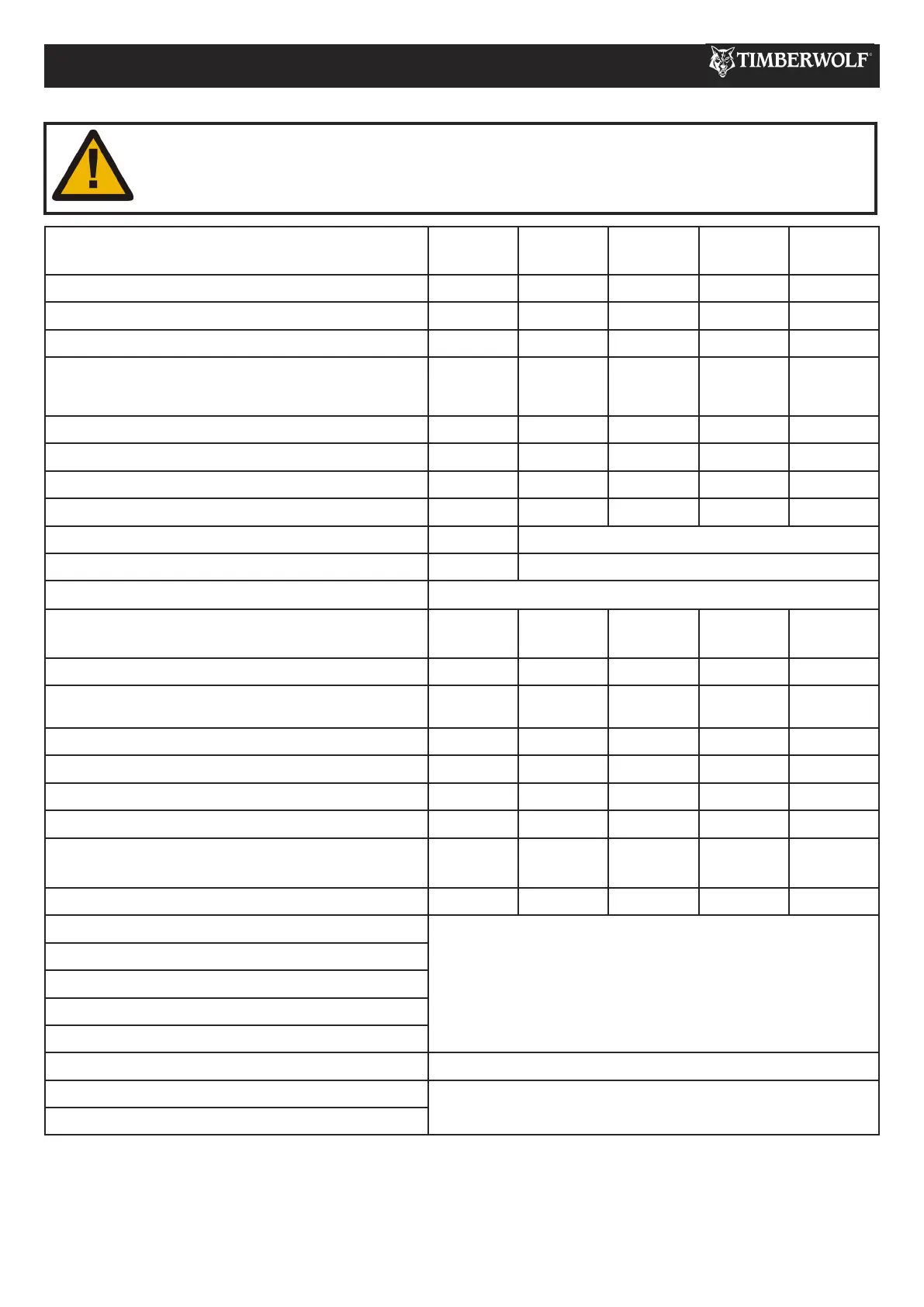

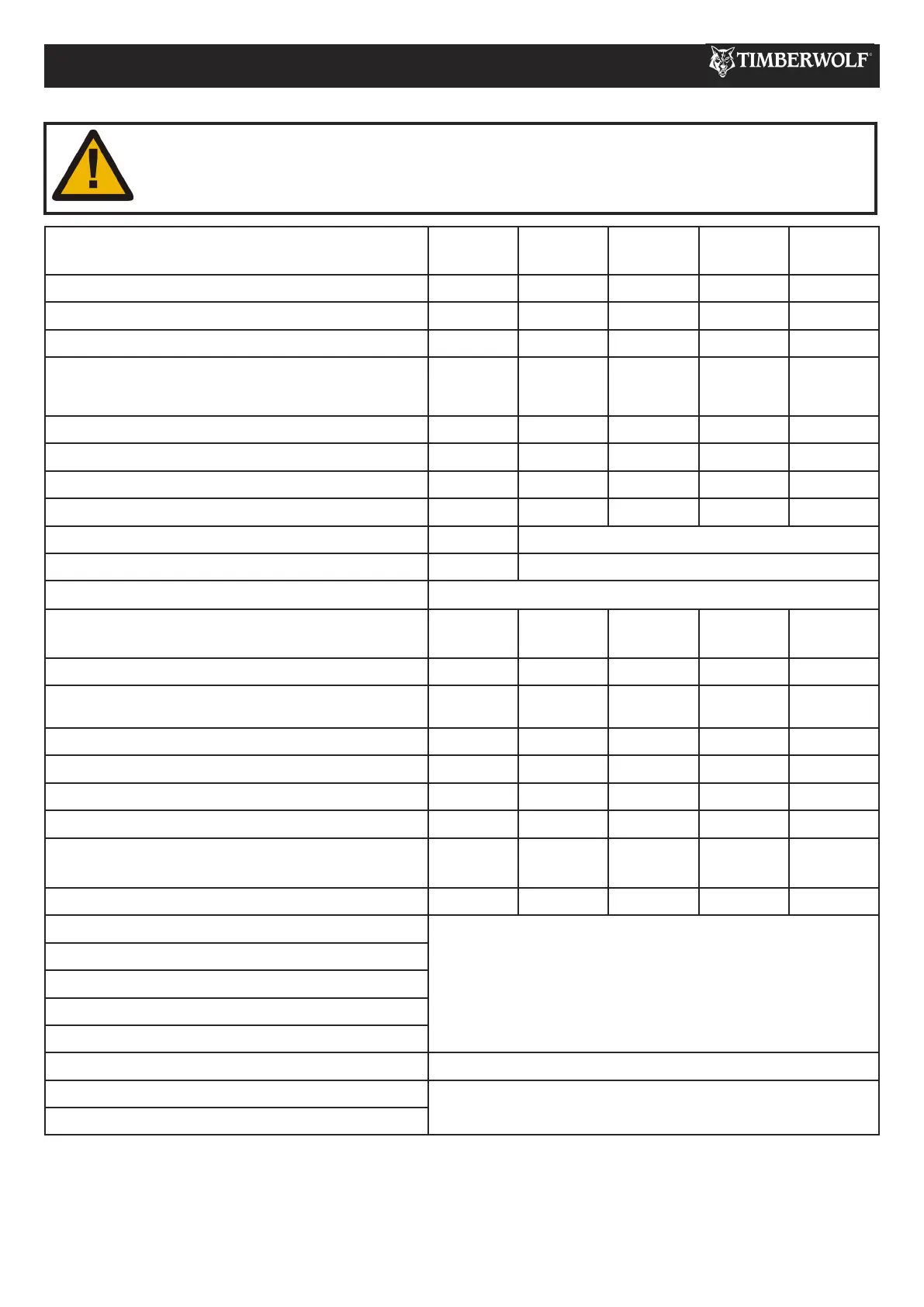

SERVICE SCHEDULE

Daily

Check

50

Hours

100

Hours

500

Hours

1

Year

Check engine oil - top up if necessary (10W-30).

ü

Check for engine oil / hydraulic oil leaks.

ü

Check fuel level.

ü

Check feed funnel, feed roller cover, access covers,

engine covers and discharge unit are securely fied.

ü

Check blades

ü

Ensure engine air intake is free from leaf build up.

ü

Check tyre pressure is 2.2 Bar (32 psi).

ü

Check safety bar mechanism.

ü

Grease the roller box slides.

ü

OR AS REQUIRED - SEE PAGE 20

Grease the roller spline and bearing.

ü

OR AS REQUIRED - SEE PAGE 20

Clean air filter element.

DEPENDING ON WORKING ENVIRONMENT

Check for tightness all nuts, bolts and fastenings

making sure nothing has worked loose.

ü

Grease discharge flange.

ü

Check tension of main drive belts (and tension if

necessary).

ü

Check anvils for wear.

ü

Check fuel pipes and clamp bands.

ü

Check battery electrolyte level.

ü

Check for loose electrical wiring.

ü

Replace hydraulic oil filter - every year or 100 hours

after service or repair work to the hydraulic system.

ü

OR

ü

Replace hydraulic oil.

ü

OR

ü

Replace fuel pipes and clamp bands.

REFER TO YOUR ENGINE

SUPPLIERS MANUAL

Check spark plugs.

Change engine oil.

Replace engine oil filter cartridge.

Check valve clearance.

Replace anvils when worn. RETURN TO DEALER FOR ANVIL CHANGE

Axle maintenance.

REFER TO SUPPLIERS INSTRUCTION SHEET

Tow head maintenance.

SERVICE SCHEDULE

WARNING

ALWAYS IMMOBILISE THE MACHINE BY STOPPING THE ENGINE, REMOVING THE

IGNITION KEY AND DISCONNECTING THE BATTERY BEFORE UNDERTAKING ANY

MAINTENANCE WORK.

Loading...

Loading...