CHANGE BLADES

TW 160PH

SERVICE INSTRUCTIONS

18 / 51

C190-0013 11.04.2019

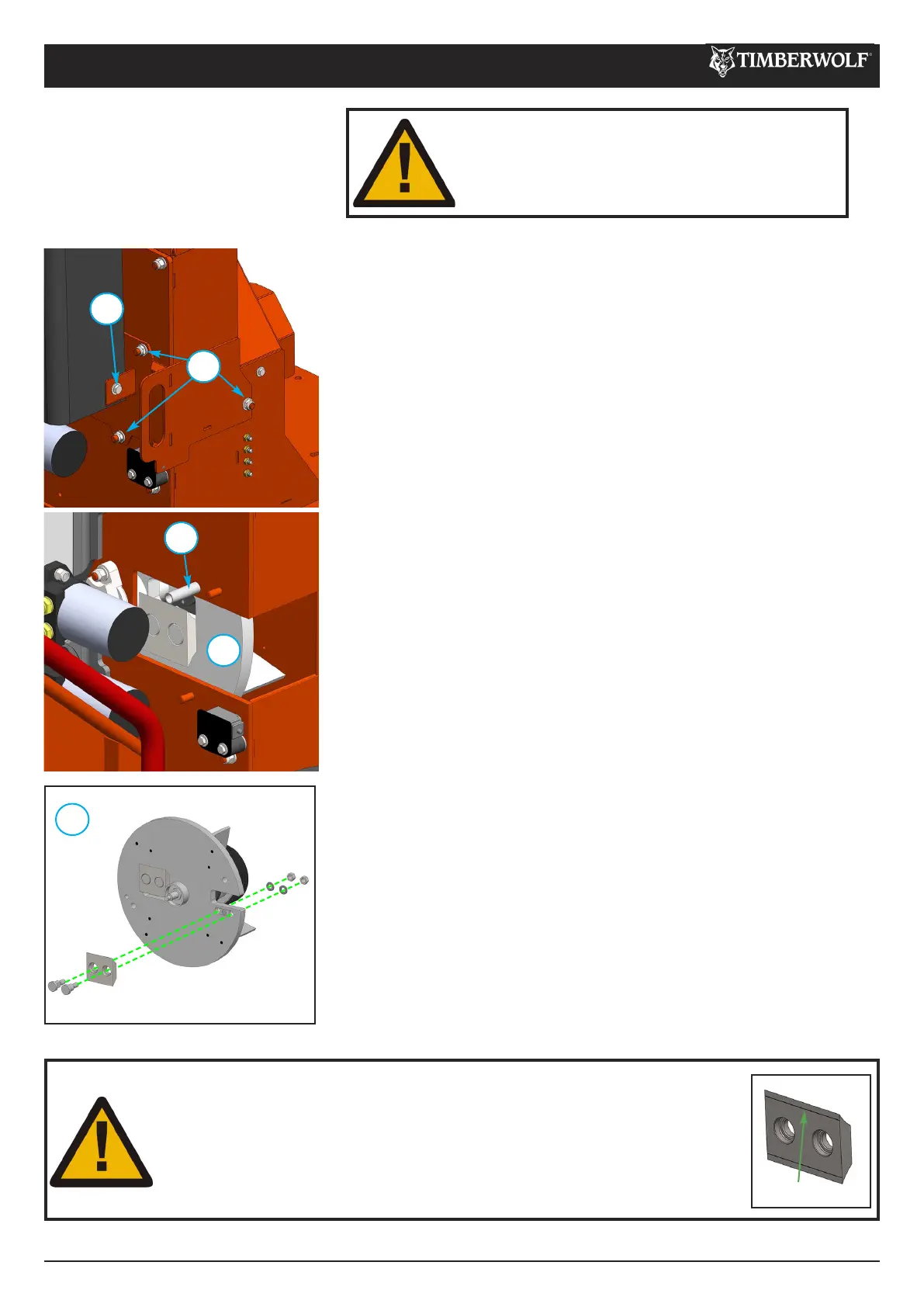

4

5

6

12

3

WARNING

WEAR RIGGERS GLOVES FOR THE BLADE

CHANGING OPERATION.

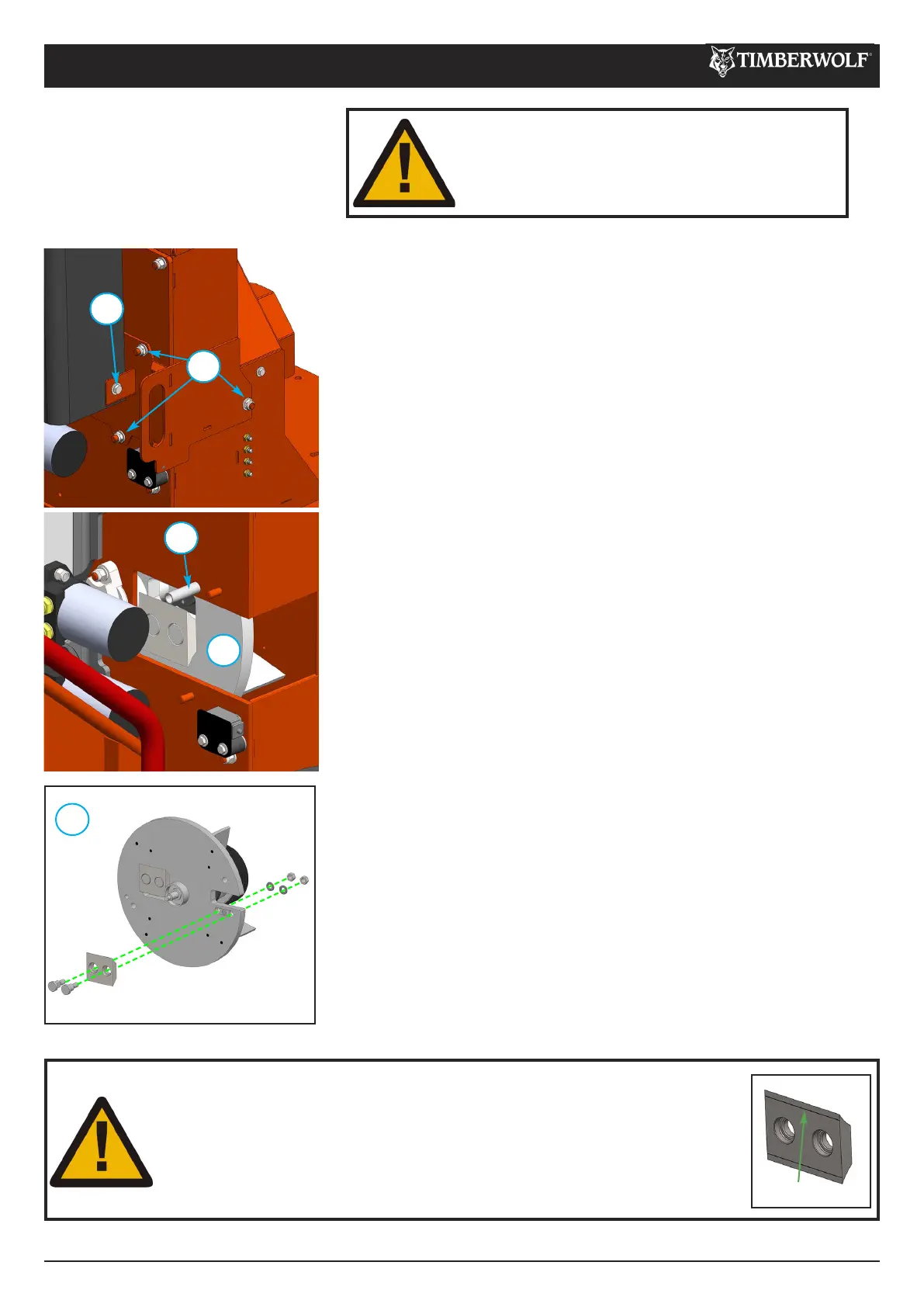

WARNING

ALWAYS SHARPEN BLADES ON A REGULAR BASIS. FAILURE TO DO SO WILL

CAUSE THE MACHINE TO UNDER PERFORM AND WILL OVERLOAD ENGINE

AND BEARINGS CAUSING MACHINE BREAKDOWN. BLADES MUST NOT BE

SHARPENED BEYOND THE WEAR MARK SEE DIAGRAM. FAILURE TO

COMPLY WITH THIS COULD RESULT IN MACHINE DAMAGE, INJURY OR

LOSS OF LIFE.

WEAR MARK

Turn the chipper off and remove the ignition keys.1

Remove battery leads.2

Remove the M10 bolt retaining the guard, allowing the guard to be3

opened.

Remove the 3 nuts retaining the access hatch, pull hatch open clear of4

the rotor housing.

Turn rotor to blade change position.5

Insert locking bar into rotor housing and rotor.6

Brush away all dirt and debris from the rotor and blades.7

With a 24mm spanner/socket undo the two nyloc nuts and washers that8

are holding the blade in place. Remove both blade bolts from the blade.

Grasp the blade by the flat edges while wearing heavy duty gloves.9

Withdraw the blade from the rotor. 10

Clean the back surface of the blade, blade bolts and blade area of the11

rotor before reseating blades. The blades must not have any material

underneath them when tightened. If they are not flat and tight they will

become loose very quickly.

Reassemble the blades, bolts, washers and nuts in the order shown in12

the diagram above. Use only genuine Timberwolf nuts and washers, as

they are of a higher grade than normally stocked at fastener

factories.Failure to use the appropriate grade nuts or washers may

result in damage, injury or death. The use of genuine Timberwolf blades

and bolts is recommended.

Apply a smear of anti seize compound (copper ease) to the bolt threads13

and back face of the nuts. Do not apply copper grease onto the counter

bore faces of the blades or bolts.

A calibrated torque wrench must be used to tighten the bolts to a14

torque setting of 125 lbs ft (170 Nm).

Remove lock pin, rotate rotor to next blade then replace lock pin and15

repeat steps 7 - 14.

Refit access hatch.16

Refit the nuts and tighten to 45lb/ft.17

Refit battery leads.18

Loading...

Loading...