TW 160PH

V-BELT TENSIONING TABLE

30 / 51

C190-0013 11.04.2019

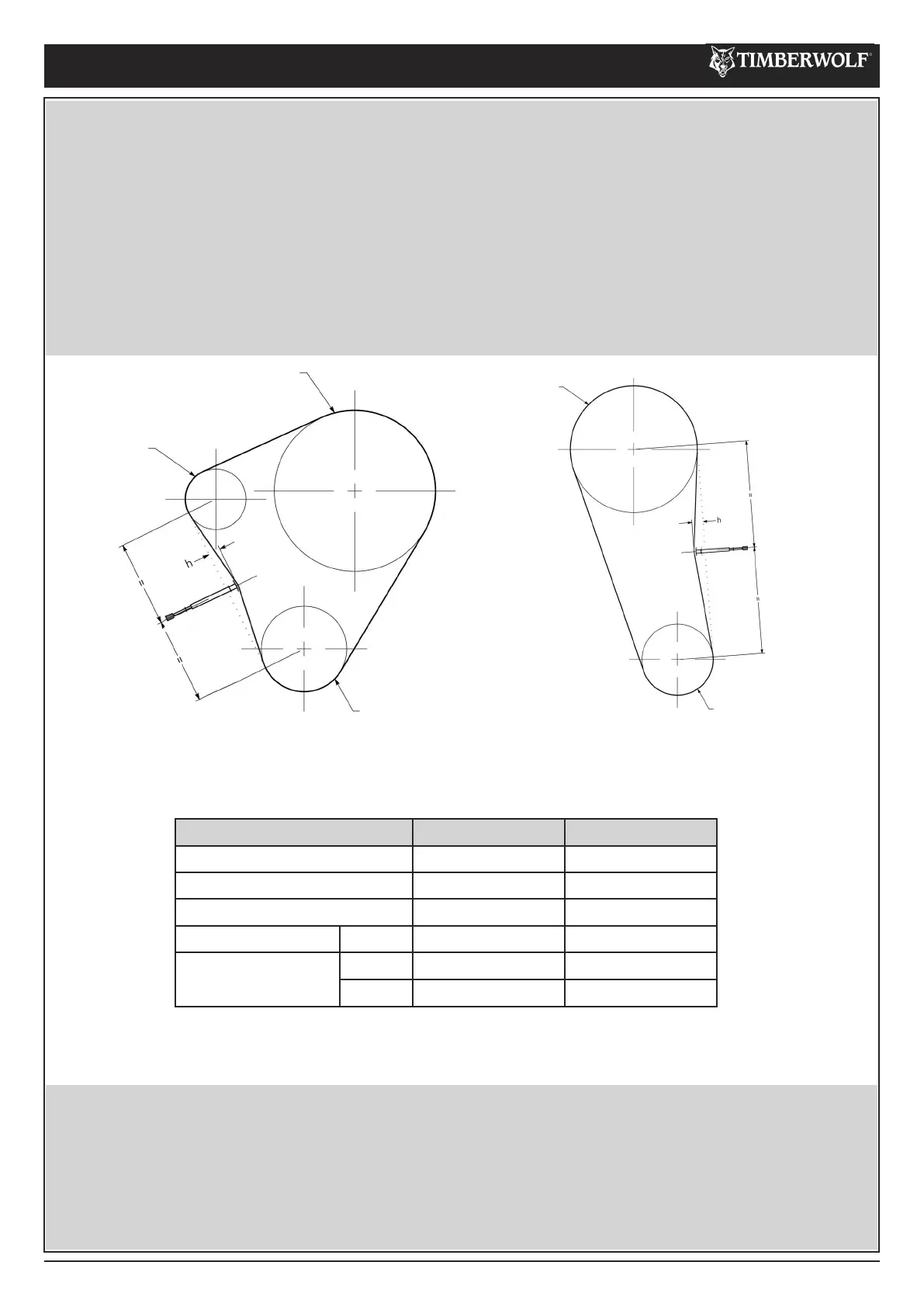

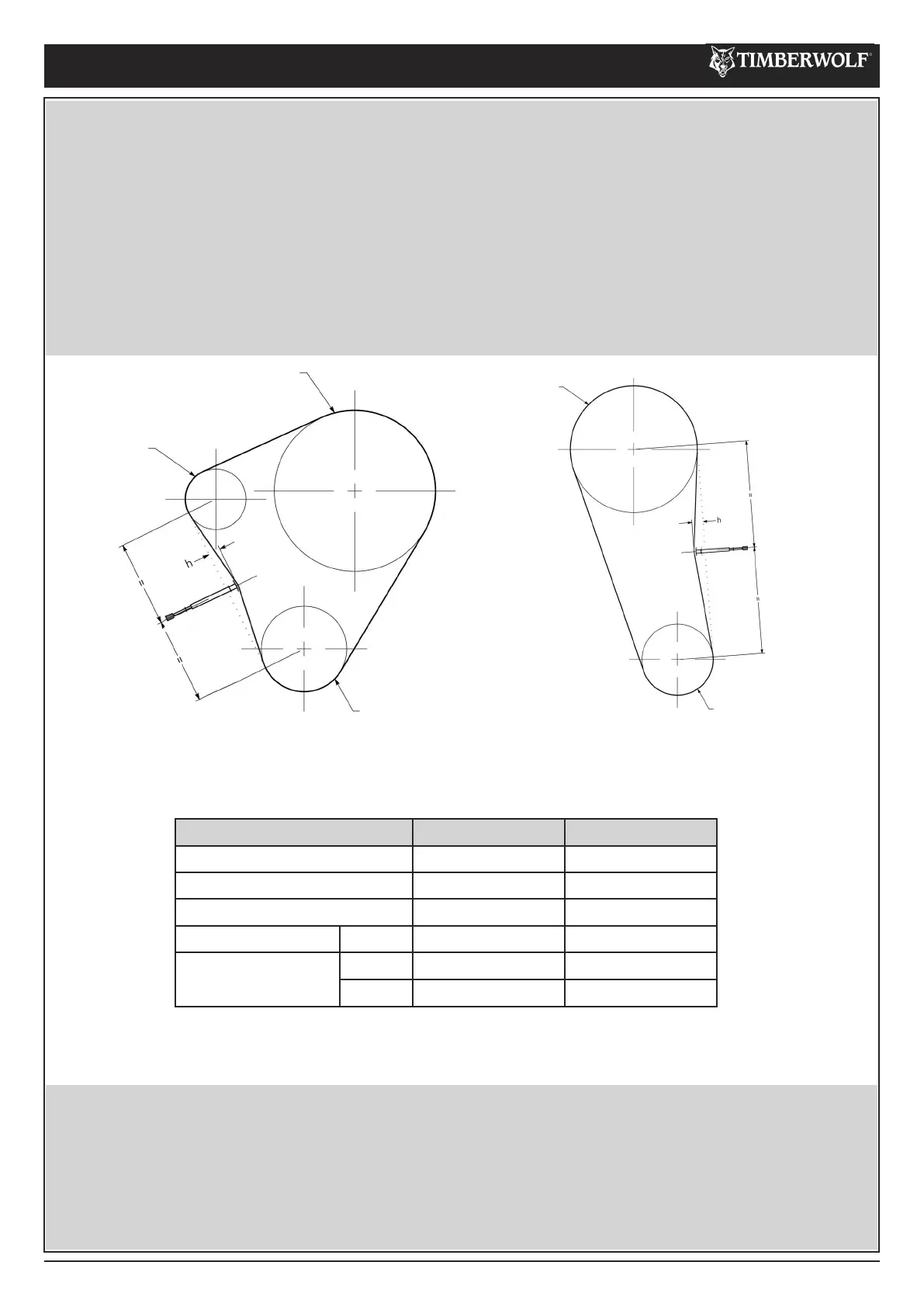

Method:

Set the deflection distance on the lower scale of the tension gauge so that the underside of the 'o'-ring equals the1

'h' value given in the table.

Ensure that the deflection force scale is zero'd by pushing the upper 'o'-ring all the way down.2

Place the tension gauge in the centre of the belt span as shown in the diagram.3

Press downwards on the rubber buffer, deflecting the belt until the underside of the lower 'o'-ring is level with4

the belt behind (use a straight edge if there is only 1 belt).

Take the reading from the deflection scale of the tension meter (read at the lower edge of the 'o'-ring) & compare5

this value with that given in the table.

Tighten or loosen belts as required following procedure given in this operator's manual.6

Tension gauges are available from Timberwolf spares, quoting part no. 18091

Rotor

Pulley

Engine Pulley

Belt

Tensioner

Rotor

Pulley

ROTOR BELTS

PUMP BELTS

TIPS ON BELT TIGHTENING:

There will normally be a rapid drop in tension during the•

run-in period for new belts. when new belts are fied,

check the tension every 2-3 hours & adjust unl the

tension remains constant.

The best tension for v-belt drives is the lowest tension at•

which the belts do not slip or ratchet under the highest

load condion.

Too much tension shortens belt & bearing life.•

Too lile tension will affect the performance of your•

machine especially in respect of no-stress devices.

Ensure that belt drives are kept free of any foreign•

materials.

If a belt slips - ghten it! •

Pump

Pulley

160PH Rotor Belts Pump Belts

Belt Mffr / Type Gates Super HC-MN Gates Super HC-MN

Belt Pitch Designaon SPA SPA

Belt Length in mm 1030 900

Belt Deflecon in mm = h 2 2

Force Reading (Kg)

New belt 3.75 - 4.01 3.94 - 4.22

Used Belt 3.21 - 3.47 3.38 - 3.66

Loading...

Loading...