Cleanup

Maintaining a clean gun is important to ensure

trouble-free operation. Flush the gun after

each use and store in a dry location. Do not

leave the gun or any of its parts in water or

solvents.

Special cleanup instructions for

use with ammable solvents:

• Always ush spray gun preferably outside

and at least one hose length from spray

pump.

• If collecting ushed solvents in a one

gallon metal container, place it into an

empty ve gallon container, then ush

solvents.

• Area must be free of ammable vapors.

• Follow all cleanup instructions.

tention

The sprayer, hose, gun and

gun lter should be cleaned

thoroughly after daily use.

Failure to do so permits material

to cake, seriously aecting the

performance of the unit.

Always spray at the lowest

possible pressure when the

tip and tip guard have been

removed. To clean the airless gun,

hose and spray device, use only

water or a suitable solvent. Static

electricity buildup may result in a

re or explosion in the presence

of ammable vapors. Hold

the gun rmly against a metal

container while ushing.

Maintenance

Follow all safety precautions as described in

the Safety Precautions section of this manual

before proceeding.

Refer to the Parts List section

in this manual for part

identication.

Replacing/Servicing the Seal Assembly

If your spray gun leaks or spits at the tip when

you release the trigger, replace the ball valve

located on the packing seal assembly and

reverse the seat located in the diuser.

To replace the ball, order kit P/N 0538221 and

follow the instructions included with the kit.

The entire packing seal assembly can also

be replaced (less often than the ball valve).

Follow the instructions below.

Never attempt to perform

maintenance on the spray gun

without rst performing the

“Pressure Relief Procedure.”

1. Perform the “Pressure Relief Procedure”

and disconnect the uid hose from the

gun.

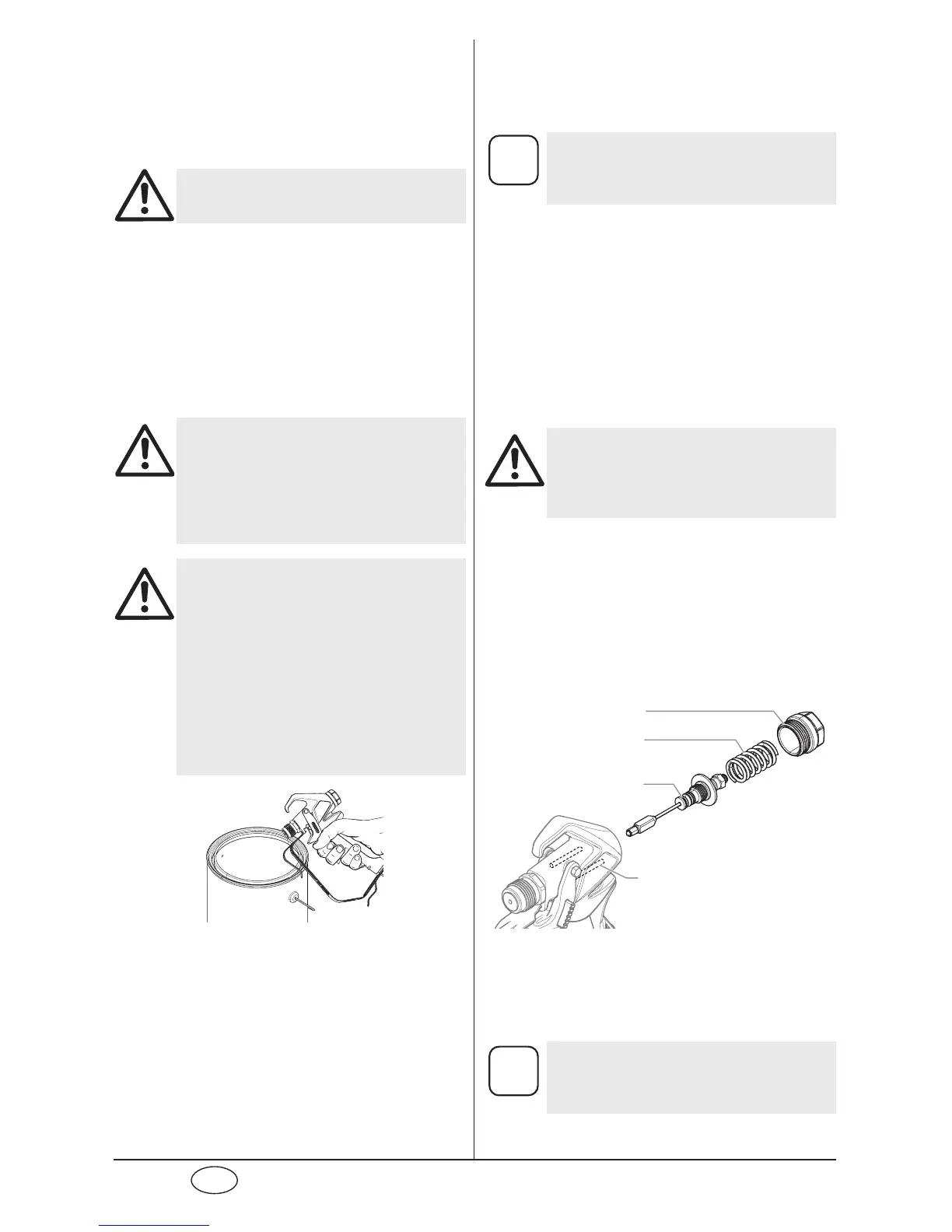

2. Remove the end cap (1) and the packing

spring (2) from the rear of the gun head.

3. Using a 3/8” socket, remove the packing

seal assembly (3) from the rear of the gun

head.

2

3

4

4. Soak the removed parts in the

appropriate solvent and wipe clean.

5. Inspect the parts for wear or damage and

use new parts during reassembly of the

gun, when necessary.

i

Lubricate all packings and

moving parts before reassembly

with a lithium-based grease.

Loading...

Loading...