InstallingtheBlades

1.Installtherstbladesothatitishorizontal,alongwith

allmountinghardwareasshowninFigure44.

Note:Tightentheboltwithyourngers.

Important:Positionthecurvedendsoftheblades

topointtowardthemachinehousing.Besureto

nesttheraisedareasoneachbladedriverwiththe

recessesintheheadofitscorrespondingspindle,

andthepinsontheothersideofeachbladedriver

withtheholesinitscorrespondingblade.

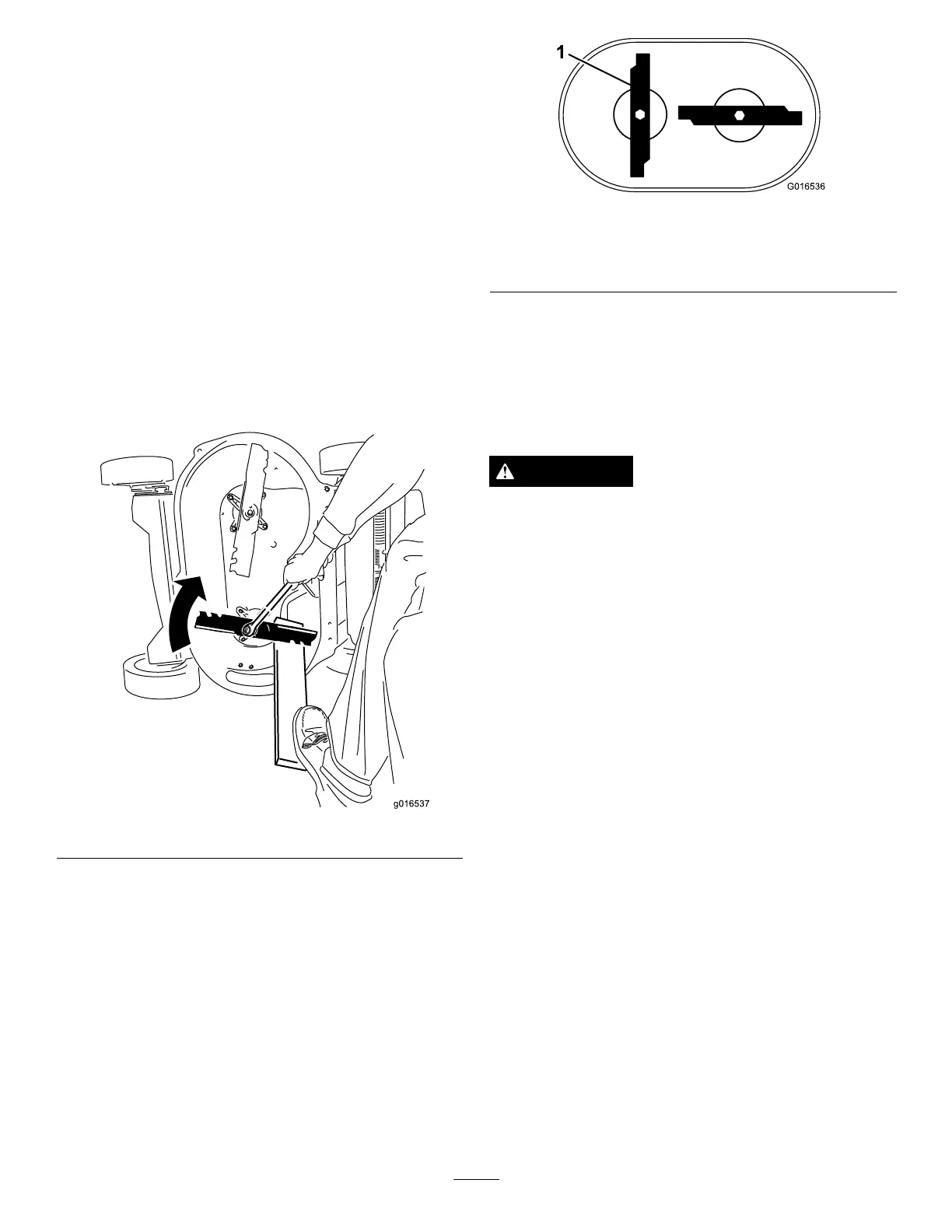

2.Steadyeachbladewithaboardandturnthebladebolt

clockwisewithatorquewrenchasshowninFigure45;

torquethebladeboltto82N-m(60ft-lb).

Important:Abolttorquedto82N-m(60ft-lb)is

verytight.Putyourweightbehindthewrenchand

tightentheboltsecurely.Thisboltisverydifcult

toovertighten.

Figure45

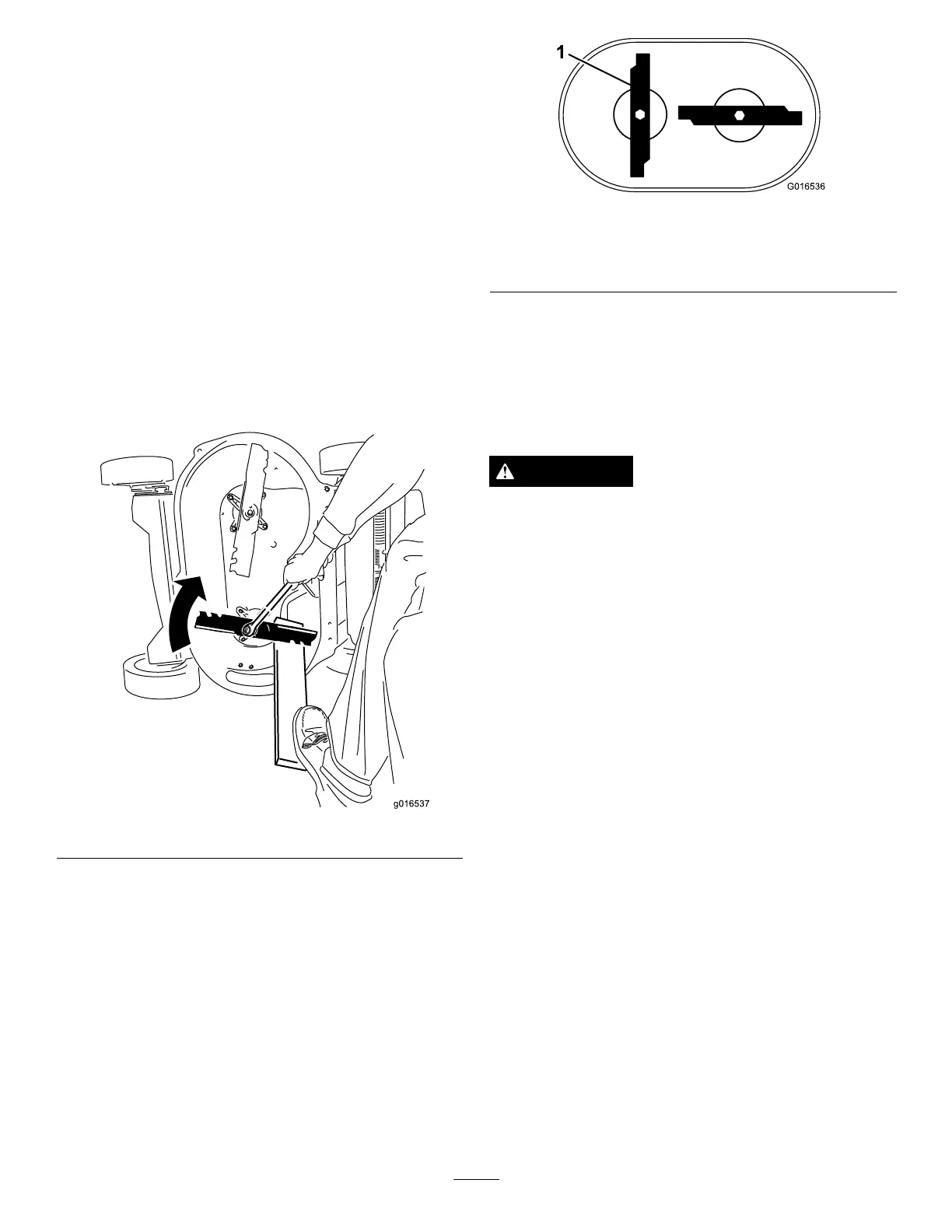

3.Rotatetheinstalledblade1/4turnuntilitisvertical,

andinstalltheotherbladeinthesamemannerasthe

rst(refertostep1).

Note:Thebladesshouldbeperpendicular,forming

aninverted“T”asshowninFigure46.

Figure46

1.Blade(2)

4.Tightenthesecondblade;refertostep2.

5.Rotatethebladesbyhandafull360°turntoensure

thattheydonottouch.

Note:Ifthebladestoucheachother,theyarenot

mountedcorrectly.Repeatsteps1through3,untilthe

bladesnolongertoucheachother.

WARNING

Incorrectlyinstallingthebladescoulddamagethe

machineorcauseaninjurytotheoperatororto

bystanders.

CleaningundertheMachine

Housing

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Lowerthemachinetoitslowestcuttingheightsetting.

RefertoAdjustingtheCuttingHeight(page9).

4.Attachahosetothewashouttting,andturnthewater

onhigh(Figure47).

Note:Spreadpetroleumjellyonthewashouttting

O-ringtomakethecouplingslideoneasierandprotect

theO-ring.

22

Loading...

Loading...