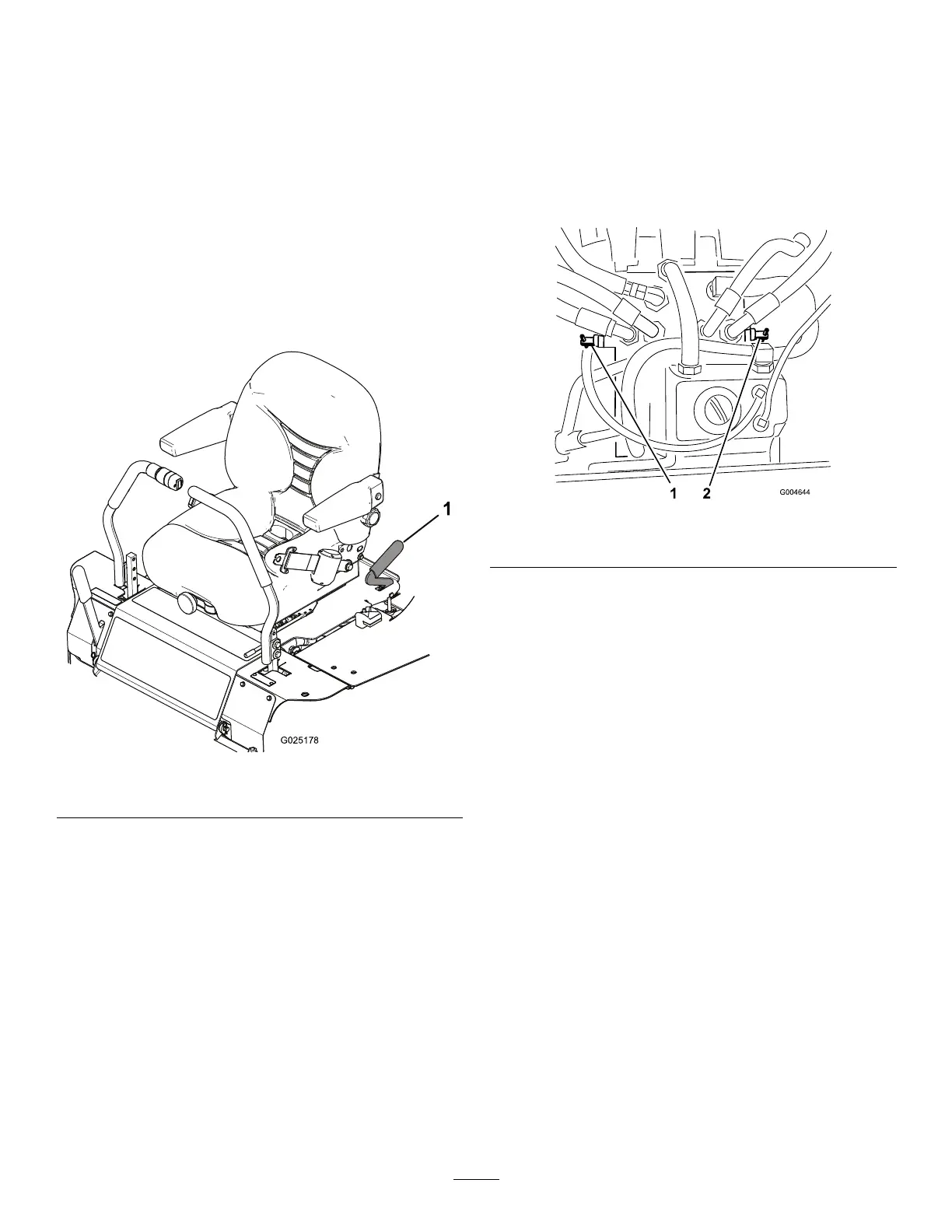

ChangingtheLumbarSupport

Thebackoftheseatcanbeadjustedtoprovideacustomized

lumbarsupportforyourlowerback.

Toadjustit,turntheknobundertheleft-sidearmrest,in

eitherdirectiontoprovidethebestcomfort(Figure49).

UnlatchingtheSeat

Toaccessthehydraulicandothersystemsundertheseat,you

needtounlatchtheseatandswingitforward.

1.Usetheseatpositionadjustmentlevertoslidetheseat

allthewayforward.

2.Liftupontheseatlatchlevertounlatchandpivotthe

seatforward(

Figure51).

Figure51

1.Seatlatch

MovingaNon-functioning

Machine

Ifthemachinebreaksdown,runsoutoffuel,etc.youmay

needtopullitwithawinchtoloaditontoatrailer.Todoso,

yourstneedtoopenthehydraulicby-passvalves.

Important:Nevertowthemachinebecausehydraulic

damagemayoccur.

MovingtheMachine

1.Disengagethepowertakeoff(PTO)andturnthe

ignitionkeytooff.Movetheleverstotheneutral

lockedpositionandapplytheparkingbrake.Remove

thekey.

2.Lifttheseat.

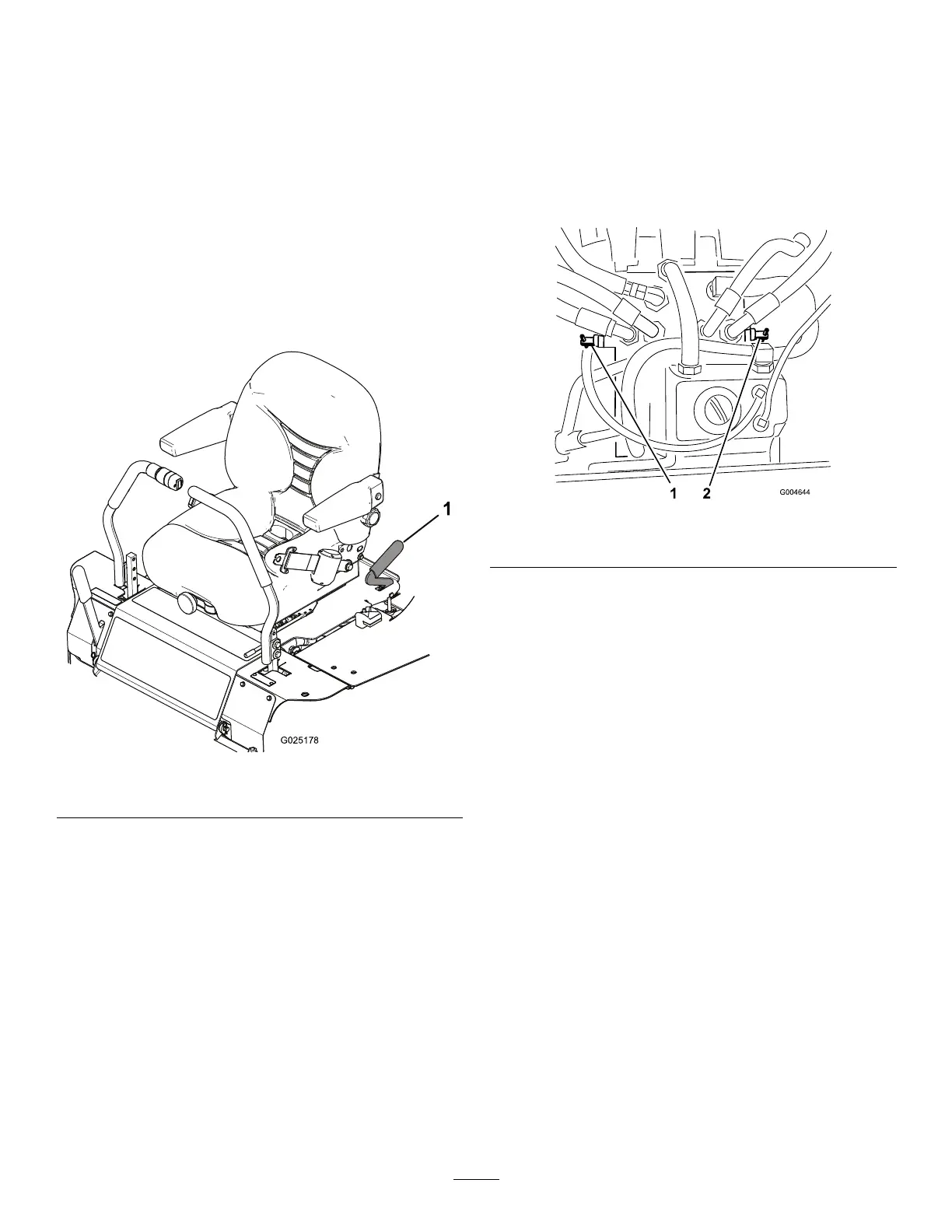

3.Rotatebothby-passvalvescounterclockwise2turns

(

Figure52).

Thisallowshydraulicuidtoby-passthepump

enablingthetrackstoturn.

Important:Donotrotatetheby-passvalvesmore

than2.5turns.Thispreventsvalvesfromcoming

outofthebodyandcausinguidtorunout.

Figure52

1.Rightby-passvalve

2.Leftby-passvalve

4.Disengagetheparkingbrakebeforemovingthe

machine.

ChangingtoMachineOperation

Rotateeachby-passvalveclockwiseandhandtightenthem

(torqueofapproximately8N-m(71in-lb))(Figure52).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveunlessby-passvalvesareturnedin.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

theendofthetracksisrecommendedinsteadofindividual

rampsforeachsideoftheunit(

Figure53).Thelowerrear

sectionofthemachineframeextendsbackbetweentherear

wheelsandservesasastopfortippingbackward.Havinga

fullwidthrampprovidesasurfacefortheframemembersto

contactiftheunitstartstotipbackward.Ifitisnotpossible

touseonefullwidthramp,useenoughindividualrampsto

simulateafullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

Figure53).Asteeperanglemaycause

attachmentcomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

27

Loading...

Loading...