BeltMaintenance

CheckingtheAlternatorBelt

Tension

ServiceInterval:Aftertherst10hours

Every200hours

1.Apply10lbofforcetothealternatorbelt,midway

betweenthepulleys.

2.Ifthedeectionisnot10mm(3/8inch),loosenthe

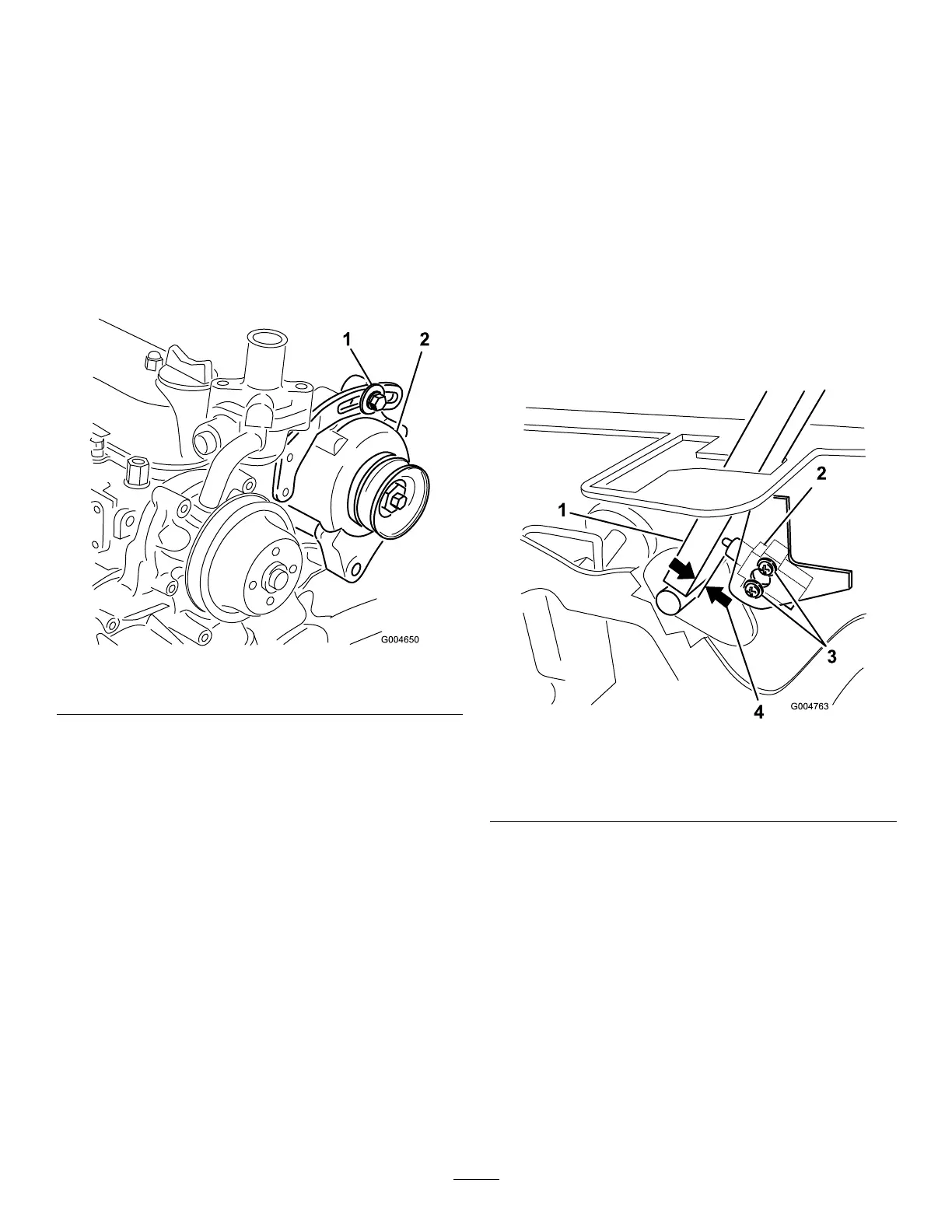

alternatormountingbolts(

Figure68).

Figure68

1.Mountingbolt2.Alternator

3.Increaseordecreasethealternatorbelttensionand

tightenthebolts.

4.Checkthedeectionofthebeltagaintoensurethat

thetensioniscorrect.

ControlsSystem

Maintenance

AdjustingtheControlLever

NeutralInterlockSwitch

1.Stopthemachine,movethecontrolleversfullyinto

theneutral-lockedposition,settheparkingbrake,and

removetheignitionkey.

2.Unlatchtheseatandpivotitforward.

Note:Ifadditionalaccessisrequiredundertheseat,

thesidepanelsmayberemoved.

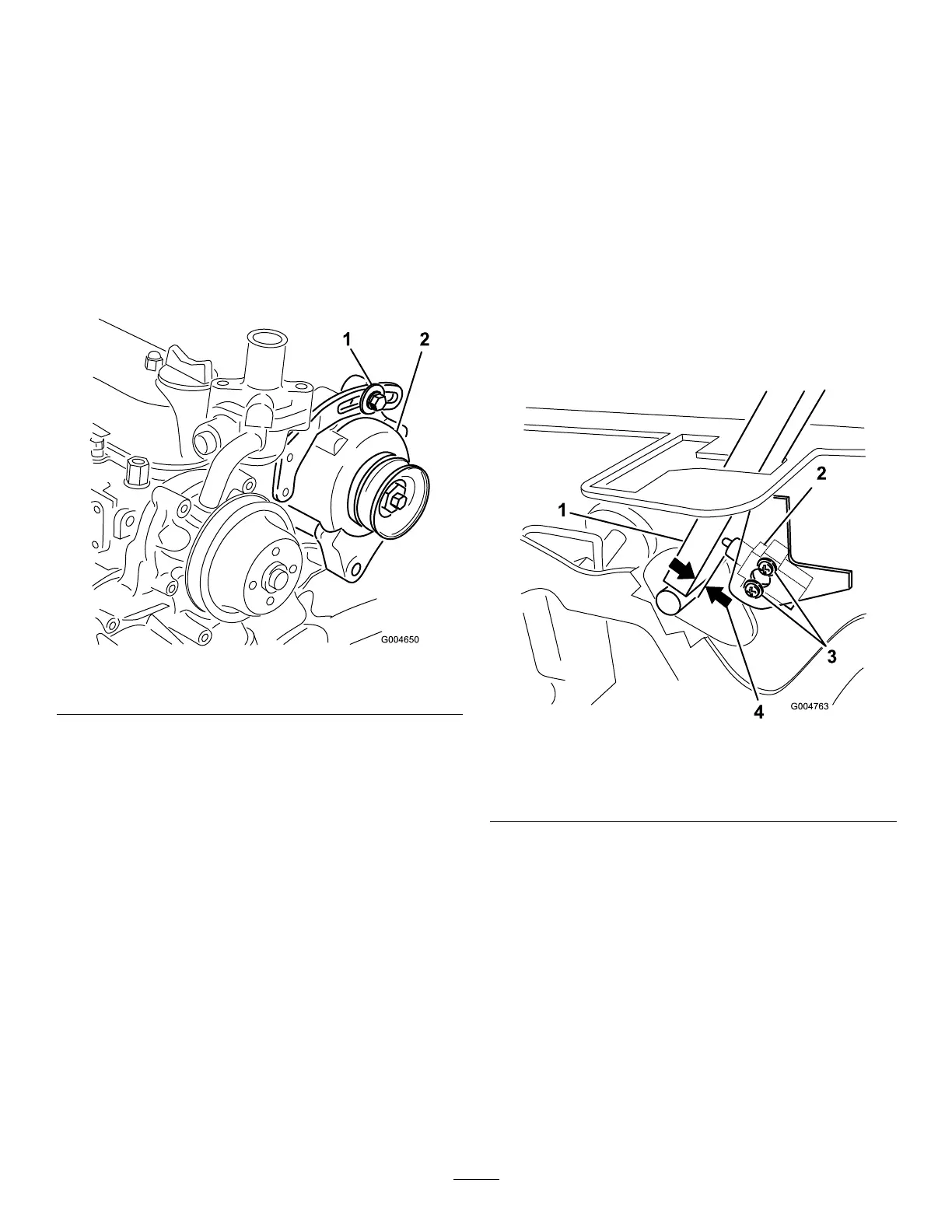

3.Loosenthe2screwssecuringtheinterlockswitch

(Figure69).

Figure69

1.Controllever3.Screws

2.Neutralinterlockswitch

4.0.4to1mm(0.015to

0.045inch)

4.Holdingthecontrolleveragainsttheframe,movethe

switchtowardtheleveruntilthedistancebetweenlever

andswitchbodyis0.015to0.045inch(0.4to1mm)

(Figure69).

5.Securetheswitch.

6.Repeatsteps3to5fortheotherlever.

7.Lowertheseat.

AdjustingtheControlLever

NeutralReturn

Ifthemotioncontrolleversdonotalignwiththeneutralslots

whenreleasedfromthereversedriveposition,adjustmentis

required.Adjusteachlever,spring,androdseparately.

40

Loading...

Loading...