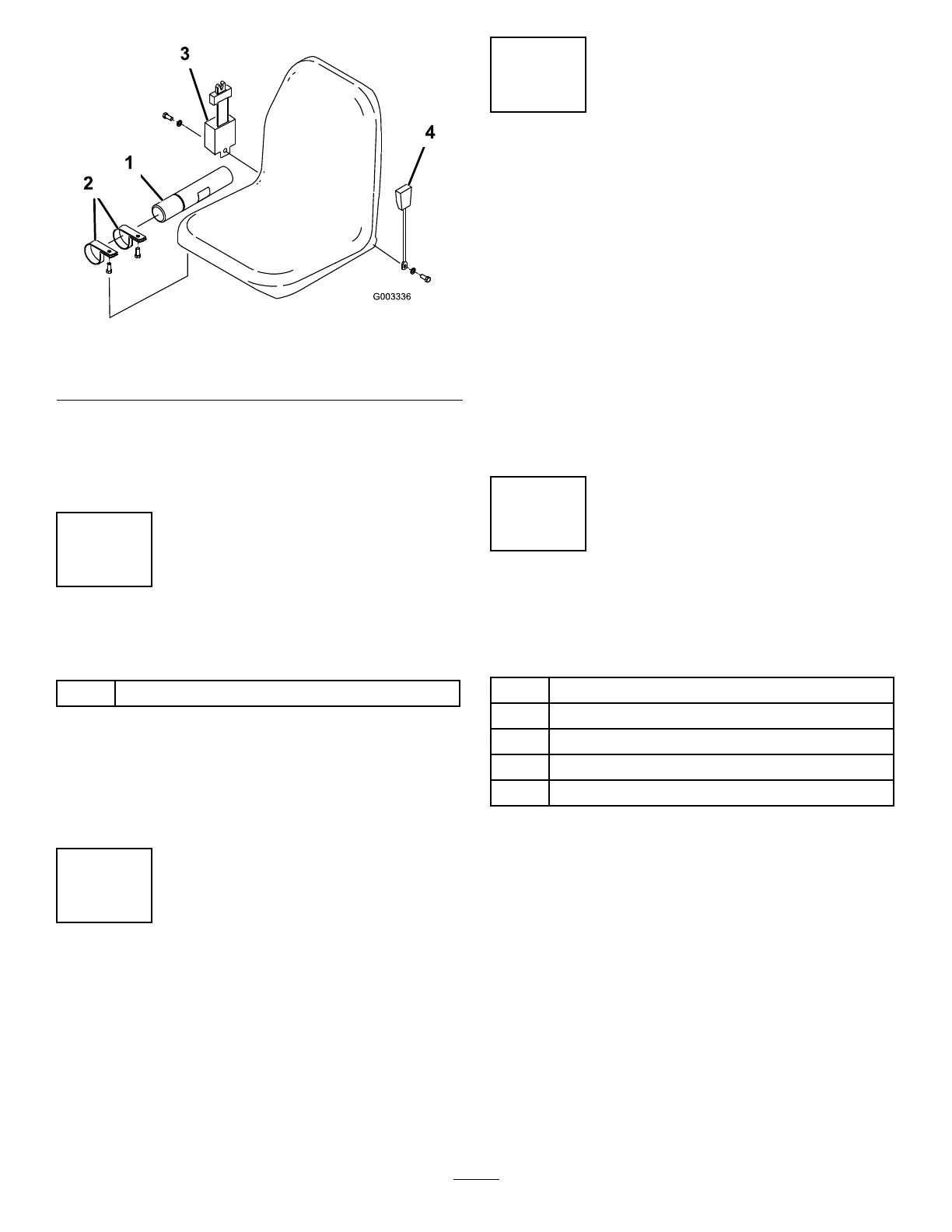

Figure3

1.Manualtube

3.Seatbeltretractor

2.R-clamp

4.Seatbeltbuckle

3.Slidetheseatcompletelyforwardandbackwardto

ensureproperoperationandthatseatswitchwires

andconnectorsarenotpinchedordonocontactany

movingparts.

2

ReplacingtheWarningDecal

Partsneededforthisprocedure:

1WarningDecal

Procedure

OnmachinesrequiringCEcompliance,replacewarning

decal,partno.107–1983withwarningdecalpartno.

105–3889.

3

GreasingtheMachine

NoPartsRequired

Procedure

Beforethemachineisoperated,itmustbegreased

toensureproperlubrication.RefertoLubrication,

page31.Failuretoproperlygreasethemachinewill

resultinprematurefailureofcriticalparts.

4

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktherearaxlelubricantlevelbeforetheengine

isrststarted,refertoCheckingtheRearAxle

LubricantinDriveSystemMaintenance,page39.

2.Checkthehydraulicuidlevelbeforetheengineis

rststarted,refertoCheckingtheHydraulicFluid

LevelinOperation,page20.

3.Checktheengineoillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOil

LevelinOperation,page20.

5

ReadingtheManualsand

ViewingtheTrainingMaterial

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

Pre-deliveryInspectionSheet

Procedure

1.Readthemanuals.

2.Viewthetrainingmaterial.

3.Storethedocumentationinasafeplace.

14

Loading...

Loading...