3.Lubricatethenewltergasketandllthelterwith

hydraulicuid.

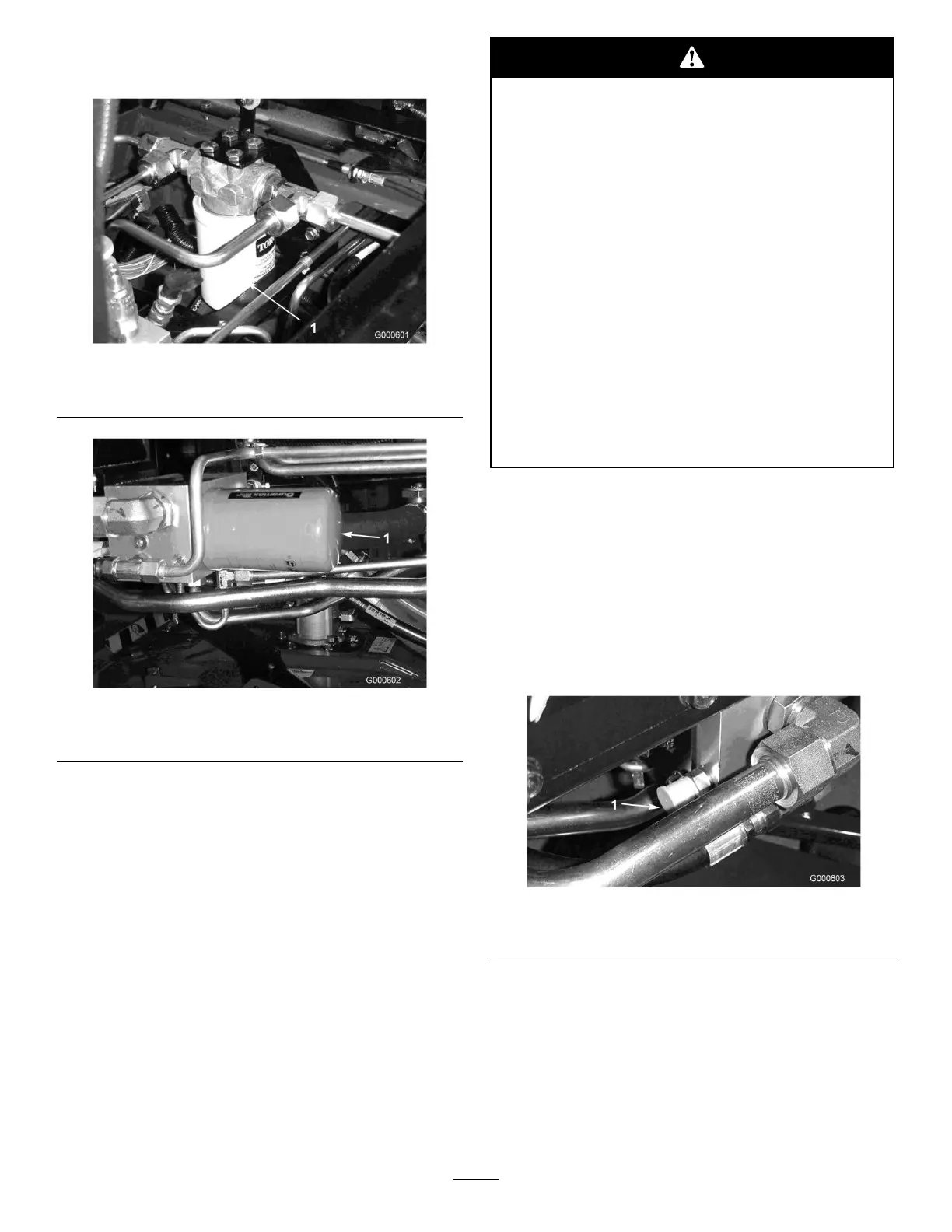

Figure56

1.Hydrauliclter

Figure57

1.Hydrauliclter

4.Ensurethattheltermountingareaisclean.Screw

thelteronuntilthegasketcontactsthemounting

plate;thentightenthelteranadditional1/2turn.

5.Starttheengineandletitrunforabouttwominutes

topurgeairfromthesystem.Stoptheengineand

checkforleaks.

CheckingtheHydraulicLines

andHoses

ServiceInterval:Beforeeachuseordaily

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.

HydraulicSystemTestPorts

Thetestportsareusedtotestthepressureinthe

hydrauliccircuits.ContactyourlocalTorodistributor

forassistanceorrefertotheServiceManual.

TestPortA(Figure58),locatedonrearoflter

manifold,underrighthandframerail.Usedtomeasure

thetractionsystemchargepressure.

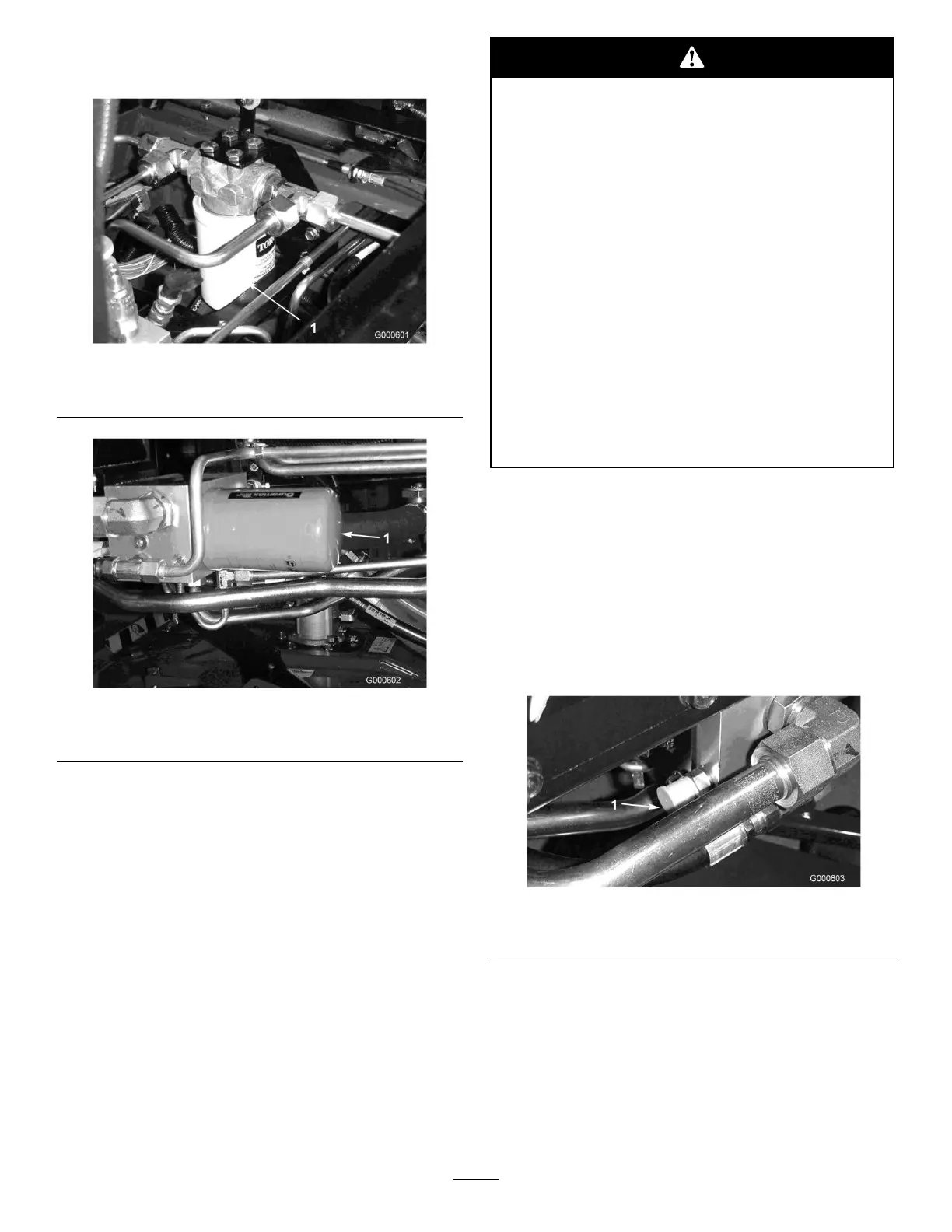

Figure58

1.T estportA(Charge)

TestPortB(Figure59),locatedonsideofcounter

balancemanifold,underoperatorsseat.Usedtomeasure

thecounterbalancepressureappliedtocuttingunitsfor

increasedtraction.

TestPortC(Figure59),locatedonfrontof2wheel

drive/4wheeldrivemanifoldthroughfrontaccesspanel

onoperatorplatform.Usedtomeasurethe4wheel

45

Loading...

Loading...