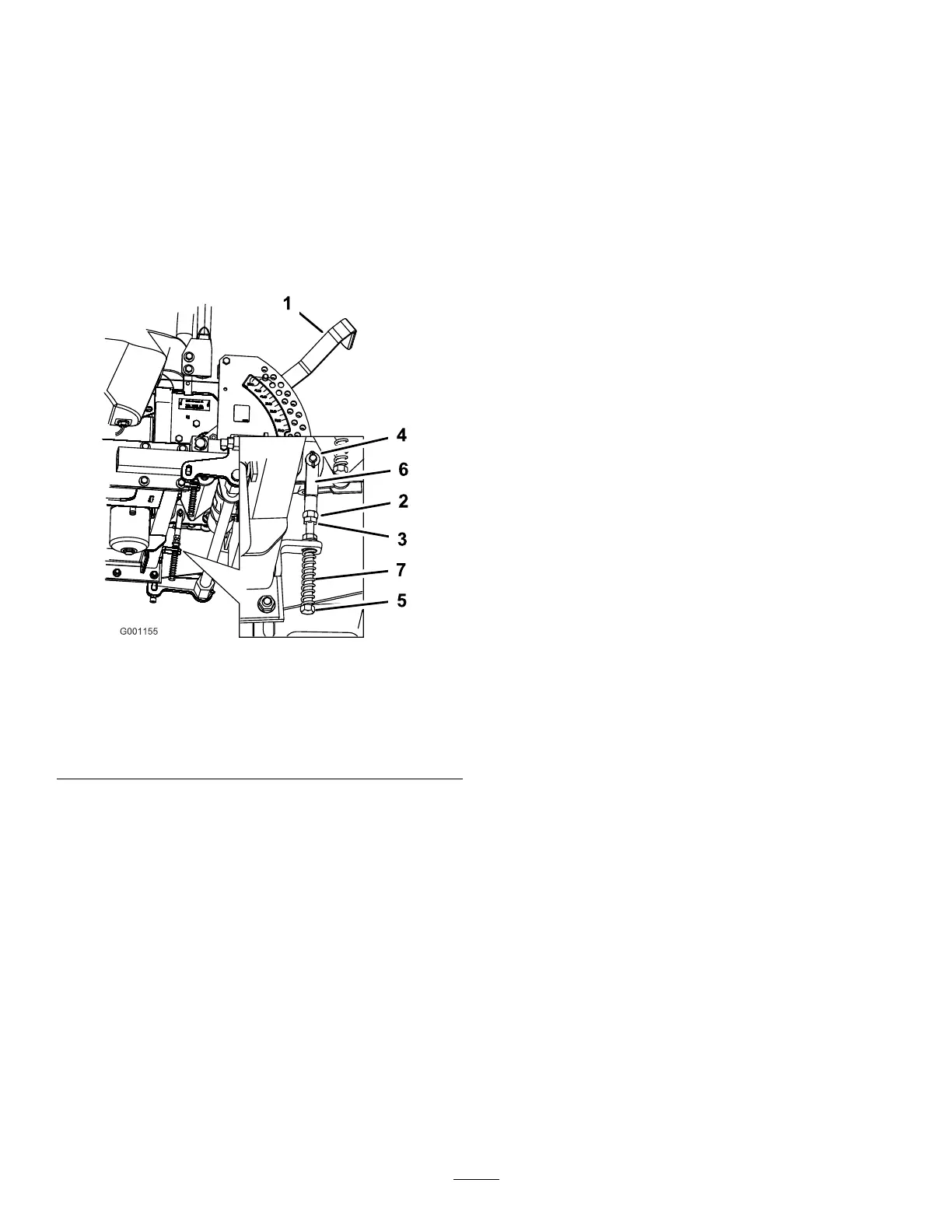

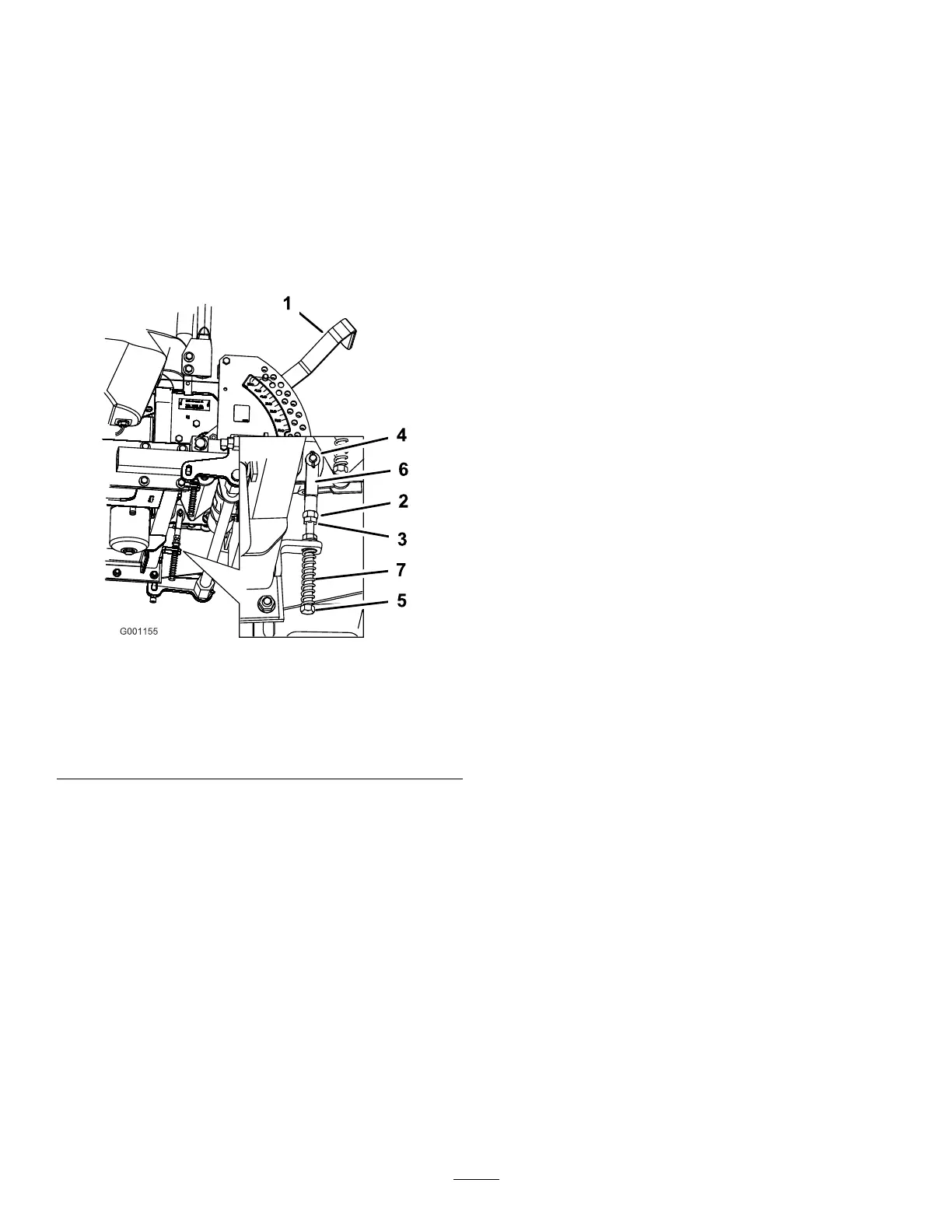

9.Applyslightrearwardpressureonthe

motion-controllever,turntheheadofthe

adjustmentboltintheappropriatedirectionuntil

thecontrolleveriscenteredintheNEUTRAL-LOCK

position(Figure67).

Note:Keeprearwardpressureontheleverto

keepthepinattheendoftheslotandtoallow

theadjustmentbolttomovethelevertothe

appropriateposition.

10.Tightenthenutandjamnut(Figure67).

11.Repeatfortheoppositesideofthemachine.

g001155

Figure67

1.Height-of-cutlever

5.Adjustmentbolt

2.Nutagainstyoke

6.Yoke

3.Jamnut

7.Spring

4.Clevispininslot

HydraulicSystem

Maintenance

ServicingtheHydraulic

System

HydraulicOilType:Toro

®

HYPR-OIL

™

500hydraulic

oilorMobil

®

115W-50oil

HydraulicSystemOilCapacity:3.9L(132oz)

Important:Useoilspecied.Otheruidscould

causesystemdamage.

CheckingtheHydraulicFluidLevel

ServiceInterval:Aftertherst8hours

Every25hours

Note:Thereare2waysofcheckingthehydraulicoil.

1iswhentheoiliswarmand1iswhentheoiliscold.

Thebafeinsidethetankhas2levelsdependingif

theoiliswarmorcold.

1.Positionthemachineonalevelsurfaceandset

theparkingbrake.

2.Cleantheareaaroundllerneckofhydraulic

tank(Figure68).

3.Removethecapfromthellerneck.Lookinside

tocheckifthereisuidinthereservoir(Figure

68).

4.Ifthereisnouid,adduidtothereservoiruntil

itreachesthecoldlevelofthebafe.

5.Runthemachineatlowidlefor15minutesto

allowanyairtopurgeoutofthesystemand

warmtheuid.RefertoStartingandStopping

theEngine(page20).

6.Rechecktheuidlevelwhiletheuidiswarm.

Theuidshouldbebetweencoldandhot.

7.Ifrequired,adduidtothehydraulictank.

Note:Theuidlevelshouldbetothetopof

thehotlevelofthebafe,whentheuidishot

(Figure68).

8.Installthecaponthellerneck.

53

Loading...

Loading...