clockwiseuntiltherubbergasketcontactsthe

lteradapter,thentightenthelteranadditional

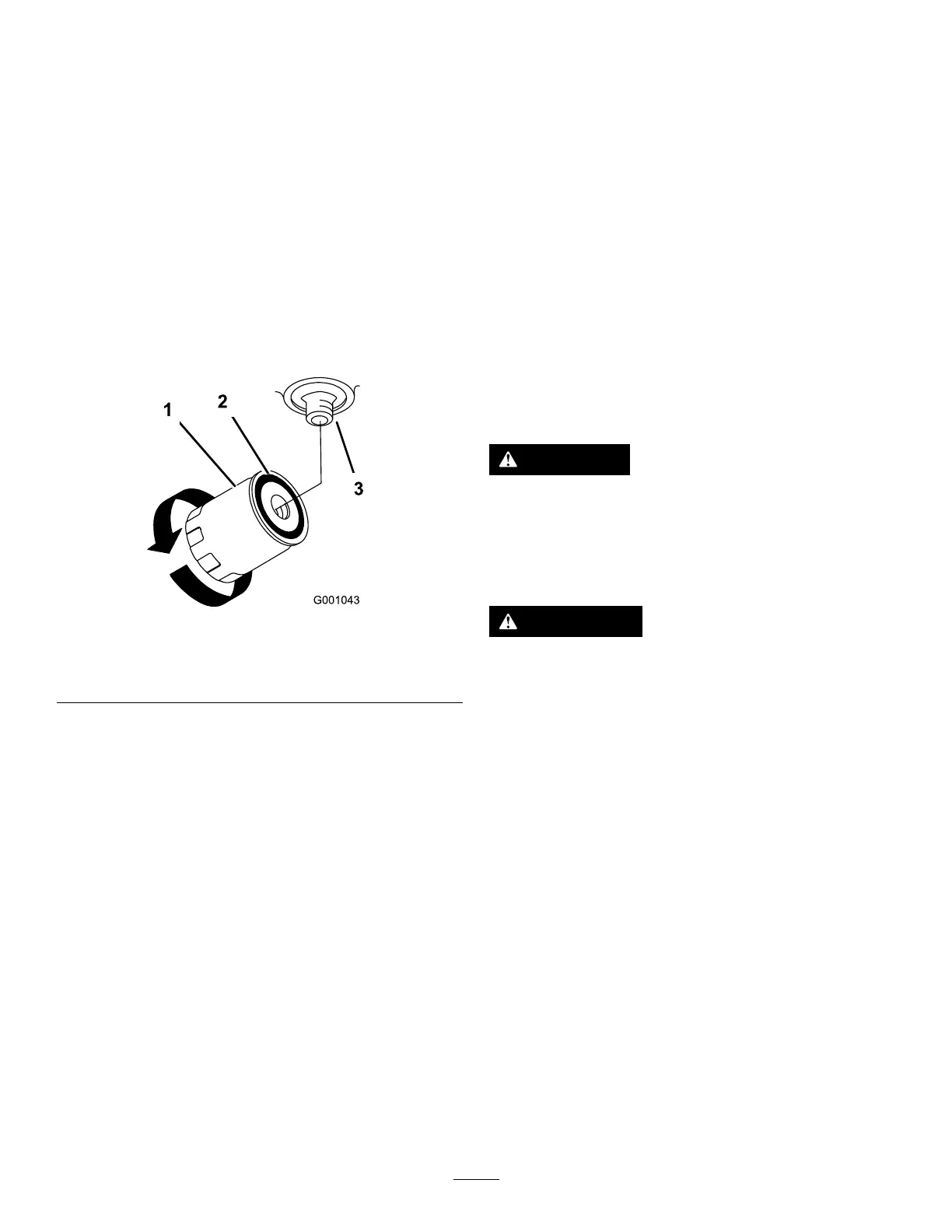

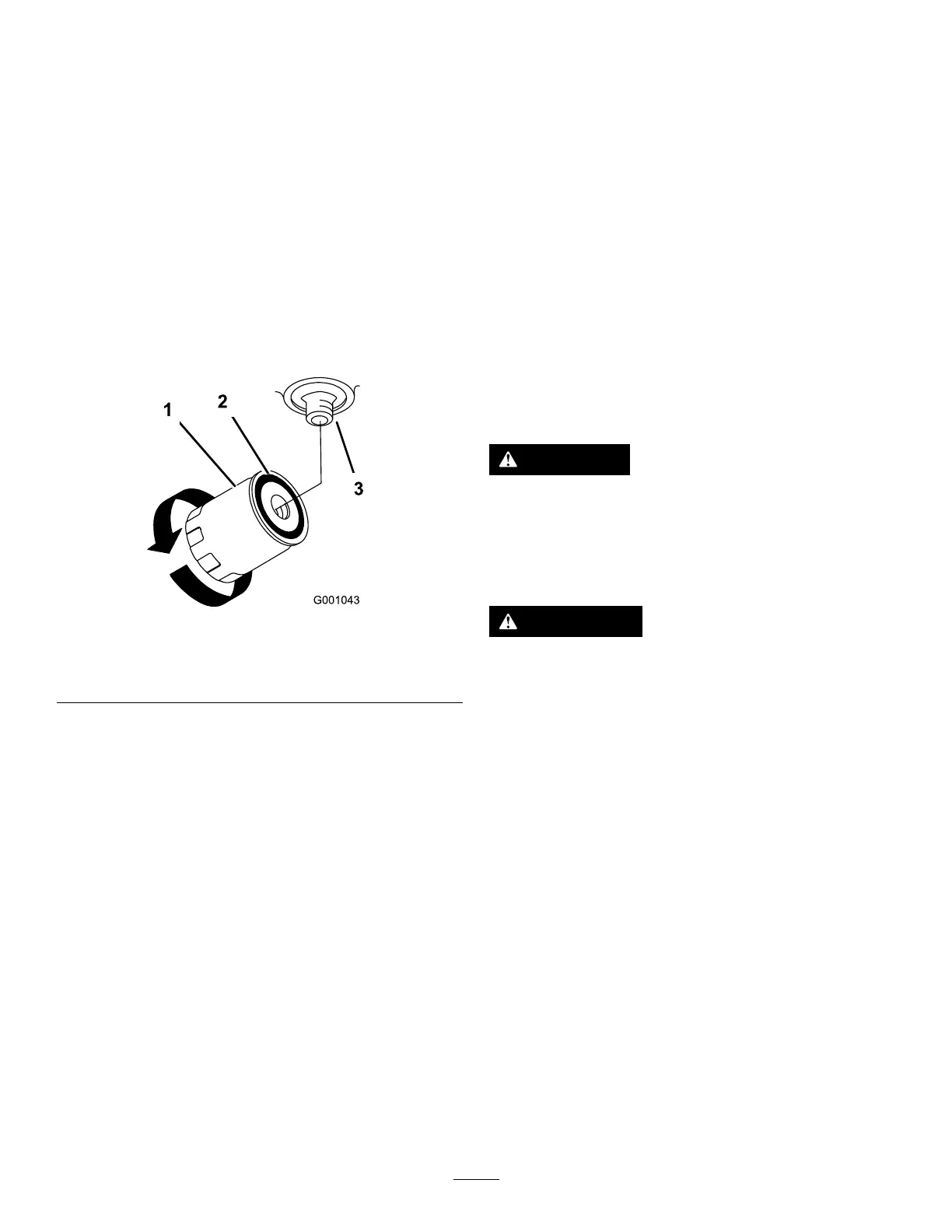

1/2turn(Figure71).

10.Cleanupanyspilleduid.

11.Adduidtothecoldlevelofthebafeinthe

hydraulictank.

12.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.Shutofftheengine

andcheckforleaks.If1orbothwheelsdonot

drive,refertoBleedingtheHydraulicSystem

(page55).

13.Rechecktheuidlevelwhiletheuidiswarm.

Theuidshouldbebetweencoldandhot.

14.Ifrequired,adduidtothehydraulictank.Do

notoverll.

g001043

Figure71

1.Hydrauliclter

3.Adapter

2.Gasket

BleedingtheHydraulicSystem

Thetractionsystemisselfbleeding,however,itmay

benecessarytobleedthesystemifuidischanged

orafterworkisperformedonthesystem.

1.Raisetherearofthemachinesowheelsareoff

thegroundandsupportitwithjackstands.

2.Starttheengineandrunatlowidlespeed.

Engagetheleverandtractionon1sideandspin

thewheelbyhand.

3.Whenthewheelbeginstospinonitsown,keep

itengageduntilwheeldrivessmoothly(minimum

2minutes).

4.Checkhydraulic-uidlevelandaddasrequired

tomaintainproperlevel.

5.Repeatthisprocedureontheoppositewheel.

CheckingtheHydraulicHoses

ServiceInterval:Every100hours

Checkthehydraulichosesforleaks,loosettings,

kinkedlines,loosemountingsupports,wear,weather

andchemicaldeterioration.Makenecessaryrepairs

beforeoperating.

Note:Keepareasaroundthehydraulicsystemclean

fromgrassanddebrisbuildup.

SettingtheHydraulicPump

NeutralPosition

Note:Adjustthehandleneutralrst.Thatneeds

tobecorrectbeforeyoucanmakethefollowing

adjustments.

Thisadjustmentmustbemadewithdrivewheels

turning.

DANGER

Mechanicalorhydraulicjacksmayfailto

supportmachineandcauseaseriousinjury.

•Usejackstandwhensupportingmachine.

•Donotusehydraulicjacks.

WARNING

Enginemustberunningsomotioncontrol

adjustmentcanbeperformed.Contactwith

movingpartsorhotsurfacesmaycause

personalinjury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromrotatingparts,

muferandotherhotsurfaces.

1.Raisetheframeandblockupthemachineso

drivewheelscanrotatefreely.

2.Disconnecttheelectricalconnectorfromthe

seatsafetyswitch.T emporarilyinstallajumper

wireacrossterminalsinthewiringharness

connector.

3.Unlatchtheseatandslideseatforward.

4.Disconnecttheseatrodandtilttheseatfully

forward.

SettingtheRightHydraulicPump

NeutralPosition

1.Starttheengine,openthethrottle1/2way,and

releaseparkingbrake;refertoStartingand

StoppingtheEngine(page20).

55

Loading...

Loading...