Note:Themotion-controllevermustbeinthe

NEUTRALpositionwhilemakinganyadjustments.

2.Adjustthepumprodlengthbyrotatingtheknob,

intheappropriatedirection,untilthewheelisstill

orslightlycreepinginreverse(Figure72).

3.Movethemotion-controlleverforwardand

reverse,thenbacktoneutral.Thewheelmust

stopturningorslightlycreepinreverse.

4.OpenthethrottletotheFASTposition.Make

surewheelremainsstoppedorslightlycreepsin

reverse,adjustifnecessary.

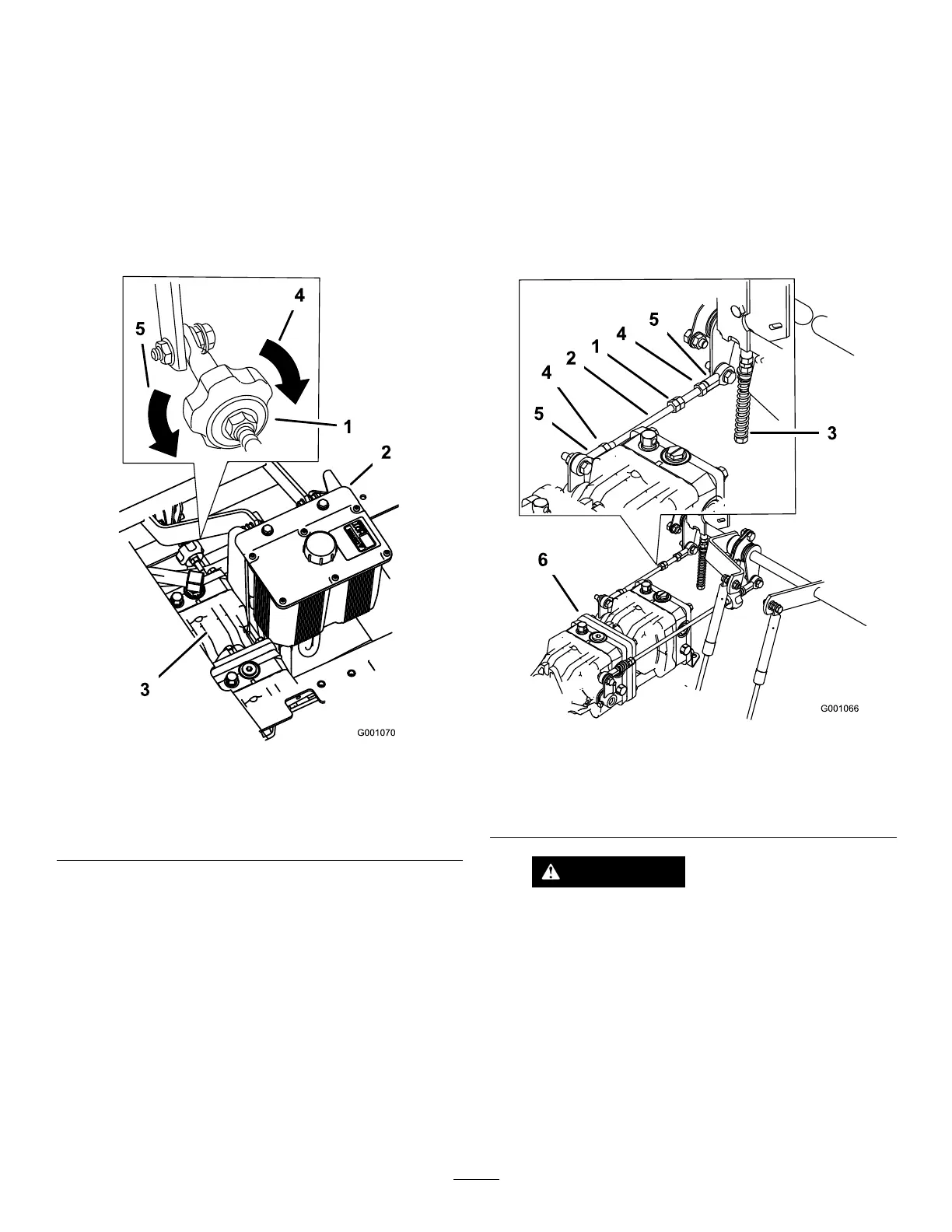

g001070

Figure72

1.Trackingknob4.Turnthiswaytotrackright

2.Hydraulictank

5.Turnthiswaytotrackleft

3.Hydraulicpumps

SettingtheLeftHydraulicPump

NeutralPosition

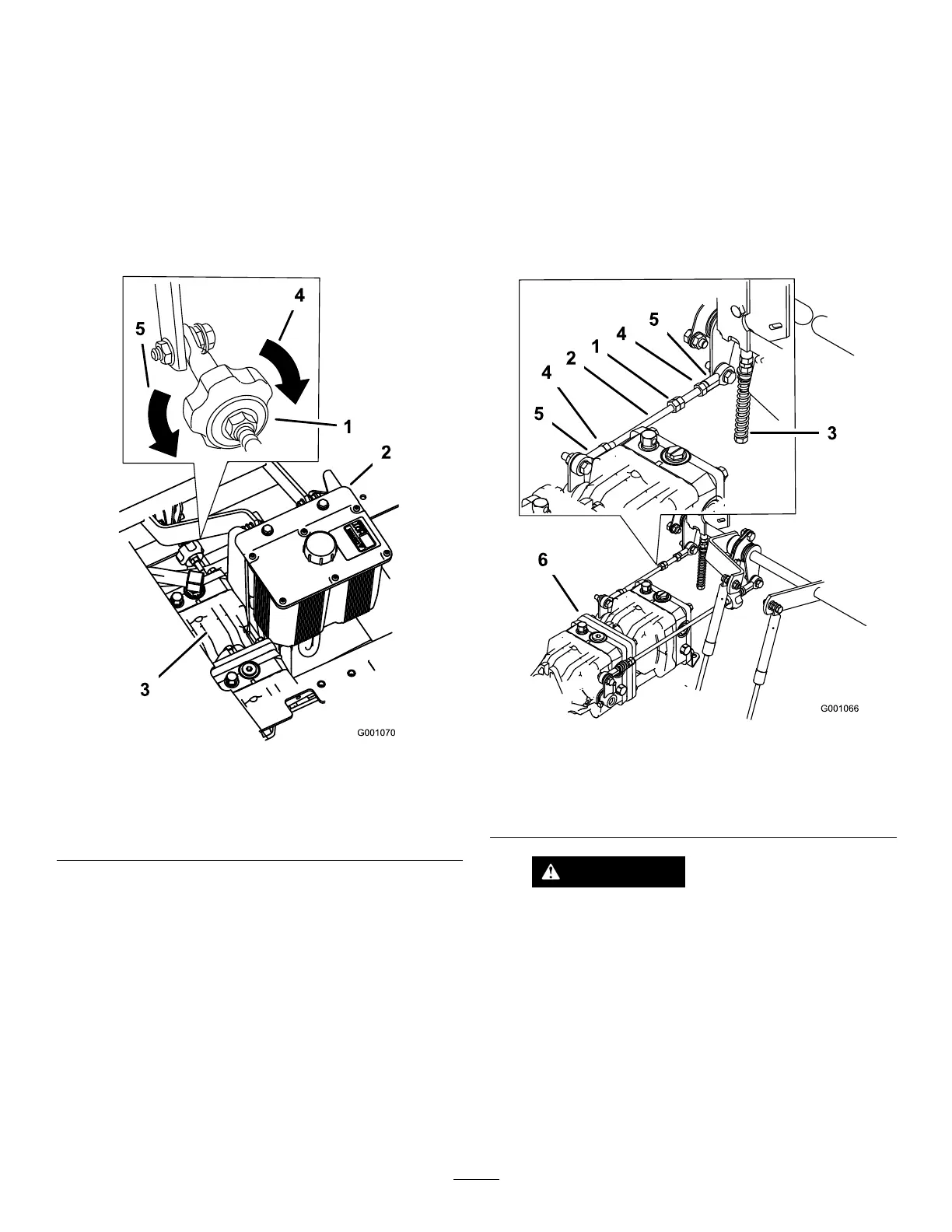

1.Loosenthelocknutsattheballjointsonthe

pumpcontrolrod(Figure73).

2.Starttheengine,openthrottle1/2way,and

releaseparkingbrake.RefertoStartingand

StoppingtheEngine(page20)

Note:Themotion-controllevermustbein

neutralwhilemakinganyadjustments.

Note:Thefrontnutonthepumprodhas

left-handthreads.

3.Adjustthepumprodlengthbyrotatingdouble

nutsonrod,intheappropriatedirection,until

wheelisstillorslightlycreepsinreverse(Figure

73).

4.Movethemotion-controlleverforwardand

reverse,thenbacktoneutral.Thewheelmust

stopturningorslightlycreepinreverse.

5.Openthethrottletofast.Makesurethewheel

remainsstoppedorslightlycreepsinreverse,

adjustifnecessary.

6.Tightenthelocknutsattheballjoints(Figure73).

g001066

Figure73

1.Doublenuts4.Locknut

2.Pumprod5.Balljoint

3.Adjustmentbolt6.Pumps

WARNING

Electricalsystemdoesnotperform

propersafetyshutoffwithjumperwire

installed.

•Removejumperwirefromwire

harnessconnectorandplug

connectorintoseatswitchwhen

adjustmentiscompleted.

•Neveroperatethisunitwithjumper

installedandseatswitchbypassed.

7.Afterbothpumpneutralsareset,shutoffthe

machine.

56

Loading...

Loading...