ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1-30amp,blade-type

•ChargeCircuit—F2-25amp,blade-type

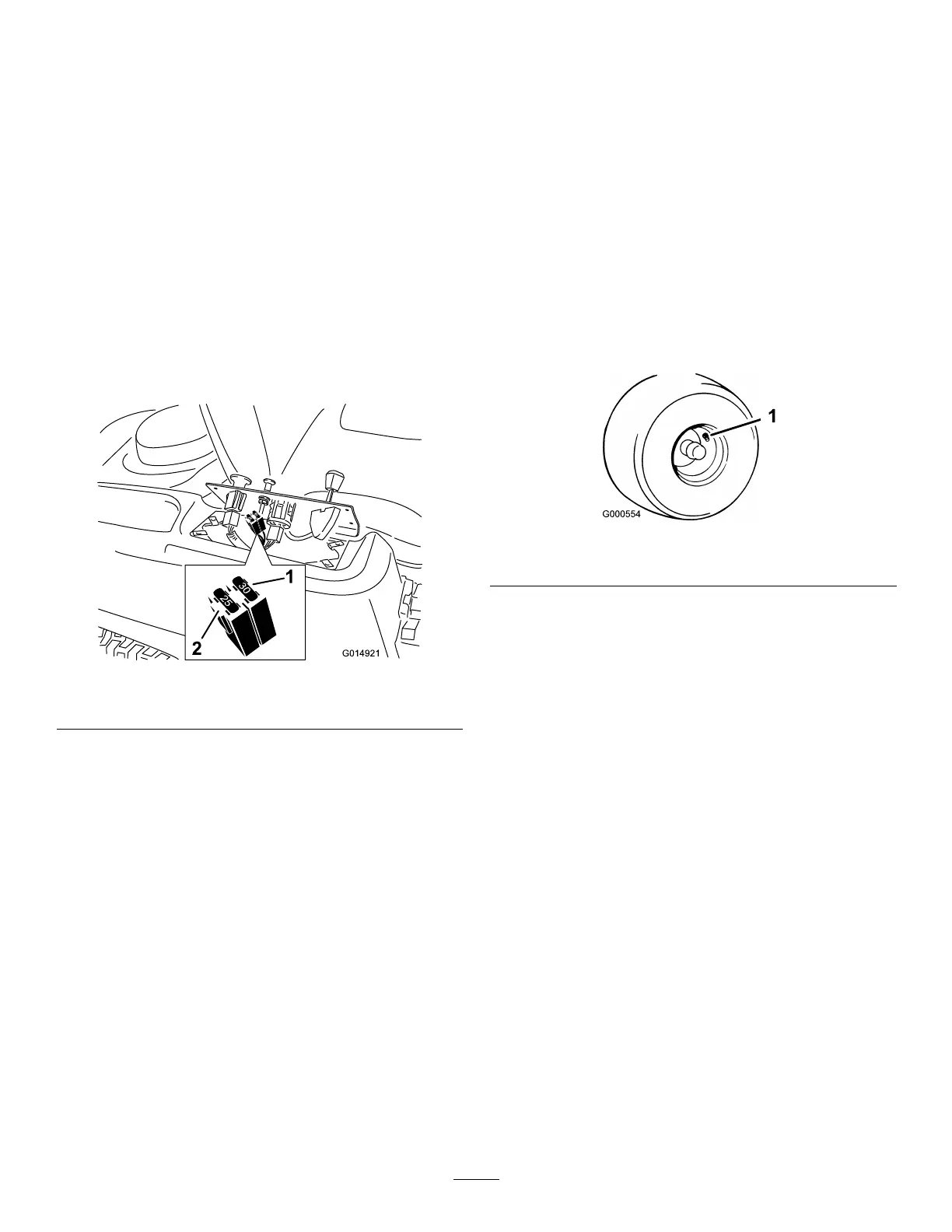

1.Removethescrewssecuringthecontrolpaneltothe

machine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(Figure49).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure49).

Figure49

1.Main—30amp

2.Chargecircuit—25amp

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslytosecure

thepaneltothemachine.

DriveSystem

Maintenance

CheckingtheTirePressure

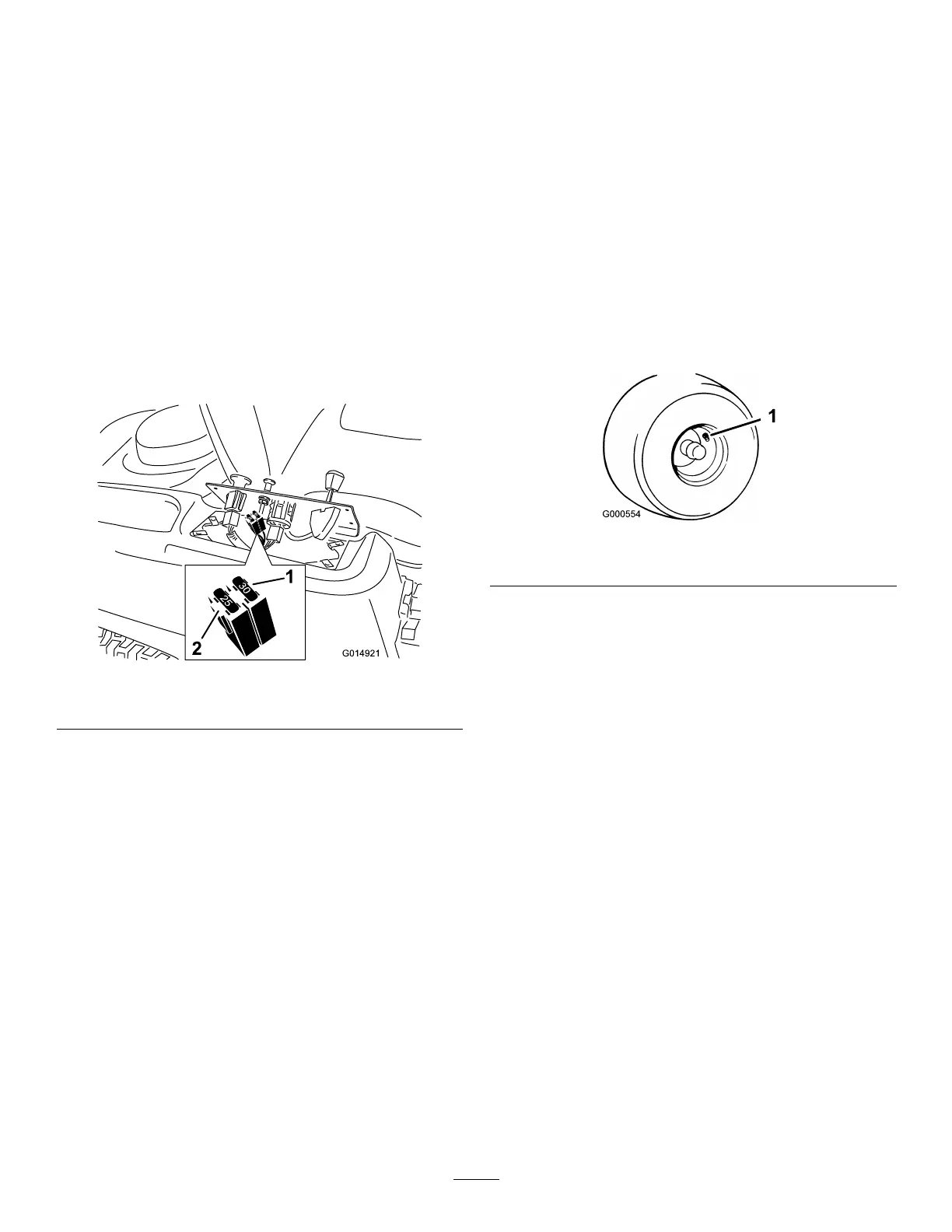

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure50).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto82kPa(13psi).

Figure50

1.Valvestem

ReleasingtheElectricBrake

Theelectricbrakereleasesbymanuallyrotatingthelinkarms

forward.Oncetheelectricbrakeisenergizedthebrakewill

reset.

Toreleasethebrake:

1.Turntheignitionkeytotheoffpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethe

brake-linkarmsareconnected(Figure51).

3.Rotatetheshaftforwardtoreleasethebrake.

41

Loading...

Loading...