byothermanufacturersmayresultinnon-conformancewith

safetystandards.

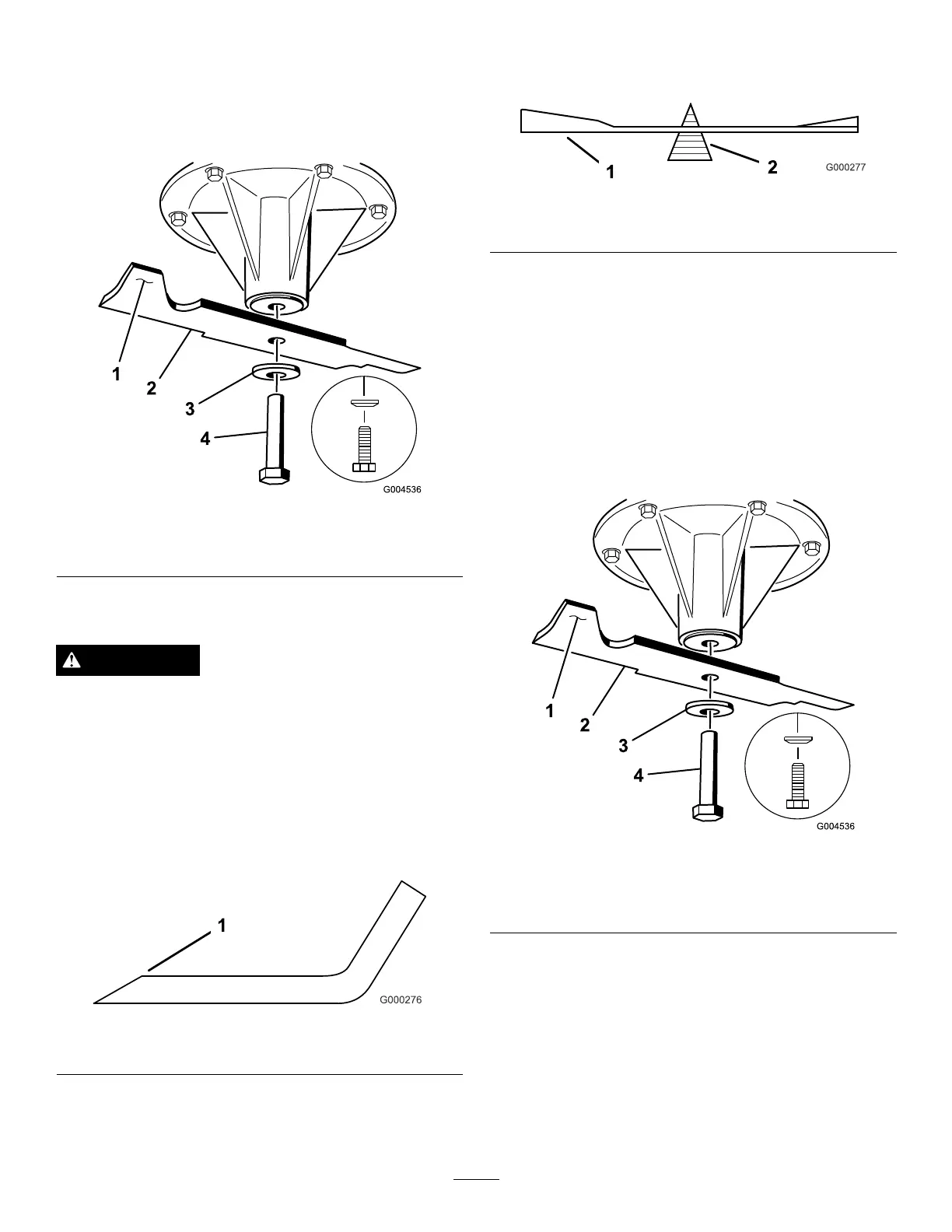

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure99).

Figure99

1.Sailareaofblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

WARNING

Whensharpeningblades,piecesofabladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure100).Maintaintheoriginalangle.The

bladeretainsitsbalanceifthesameamountofmaterial

isremovedfrombothcuttingedges.

Figure100

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure101).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(

Figure102).Repeatthisprocedure

untilthebladeisbalanced.

Figure101

1.Blade2.Balancer

InstallingtheBlades

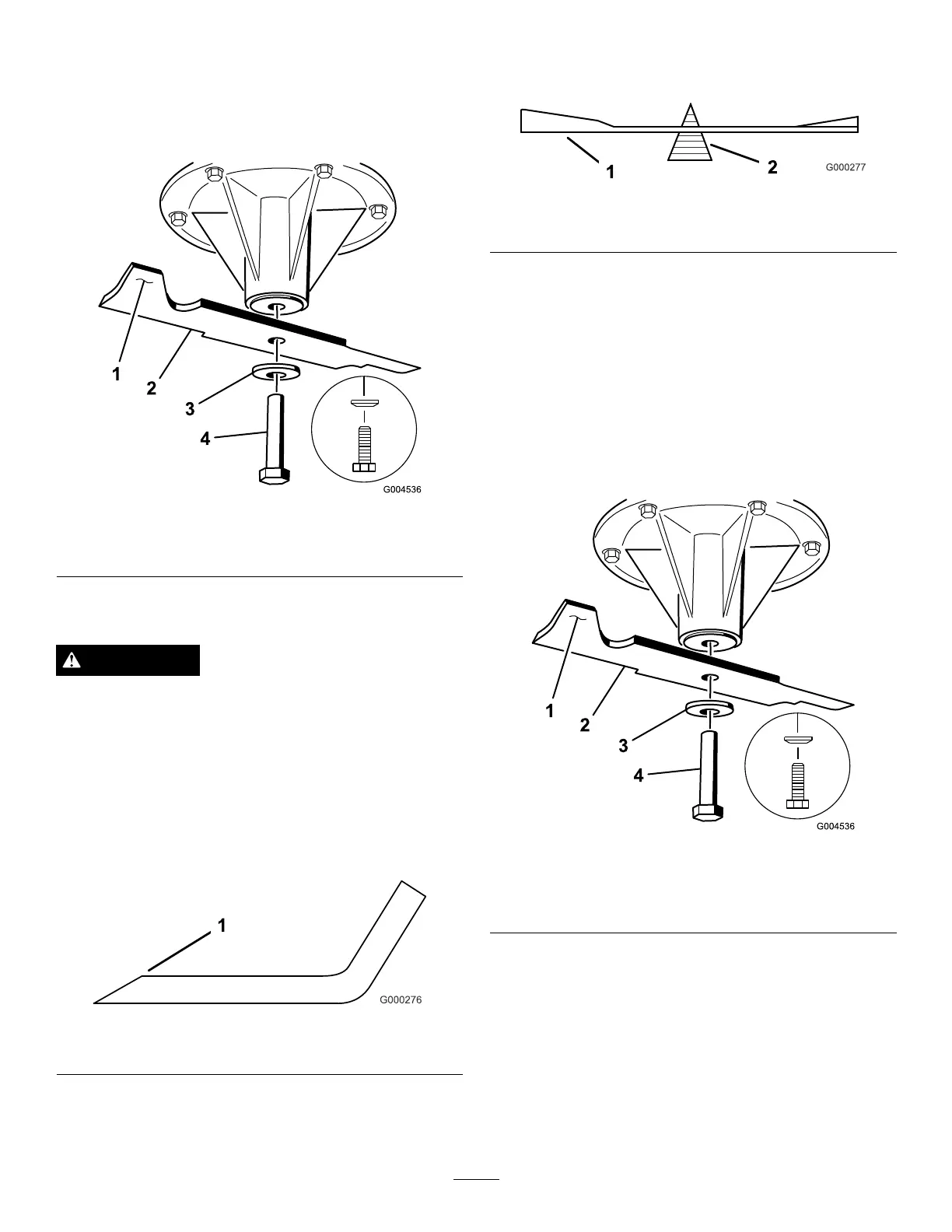

1.Installthebladeontothespindleshaft(Figure102).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandthebladebolt.Thespring

diskconemustbeinstalledtowardthebolthead

(Figure102).Torquethebladeboltto115to150N-m

(85to110ft-lb).

Figure102

1.Sailareaofblade

4.Bladebolt

2.Blade

5.Conetowardsbolthead

3.Curvedwasher

60

Loading...

Loading...