EngineMaintenance

EngineSafety

•Fuelisammableandexplosive,andcancause

personalinjury.

•Checkallfuellinesfortightnessandwear

regularly.Tightenorrepairthemasneeded.

•Tippingthemachinemaycausethefueltoleak.

Donottipthemachineatananglegreaterthan

25°.Iffuelcomesincontactwiththefuelcap,

replacethecap.

•Runtheenginedryorremovethefuelwithahand

pump;neversiphonthefuel.Ifyoumustdrainthe

fueltank,doitoutdoors.

ServicingtheEngineOil

ServiceInterval:Aftertherst20hours

Beforeeachuseordaily

Every50hours

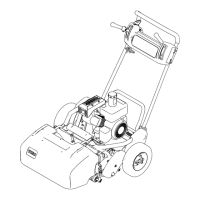

Fillthecrankcasewithapproximately0.6L(20

oz)oftheproperviscosityoilbeforestarting.The

engineusesahigh-qualityoilthathastheAmerican

PetroleumInstitute(API)serviceclassicationofSEor

higher.Selecttheproperoilviscosity(weight)based

ontheambienttemperature.Figure33illustratesthe

temperature/viscosityrecommendations.

g016841

Figure33

Note:Multi-gradeoils(5W-20,10W-30and10W-40)

increaseoilconsumption.Checktheengine-oillevel

morefrequentlywhenyouusetheseoils.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theidealtimetochecktheengine-oilleveliswhenthe

engineiscoolorbeforeyouhavestartedtheengine

fortheday.Ifyouhavealreadyrantheengine,allow

theoiltodrainbackdowntothesumpforatleast10

minutesbeforeyouchecktheengine-oillevel.

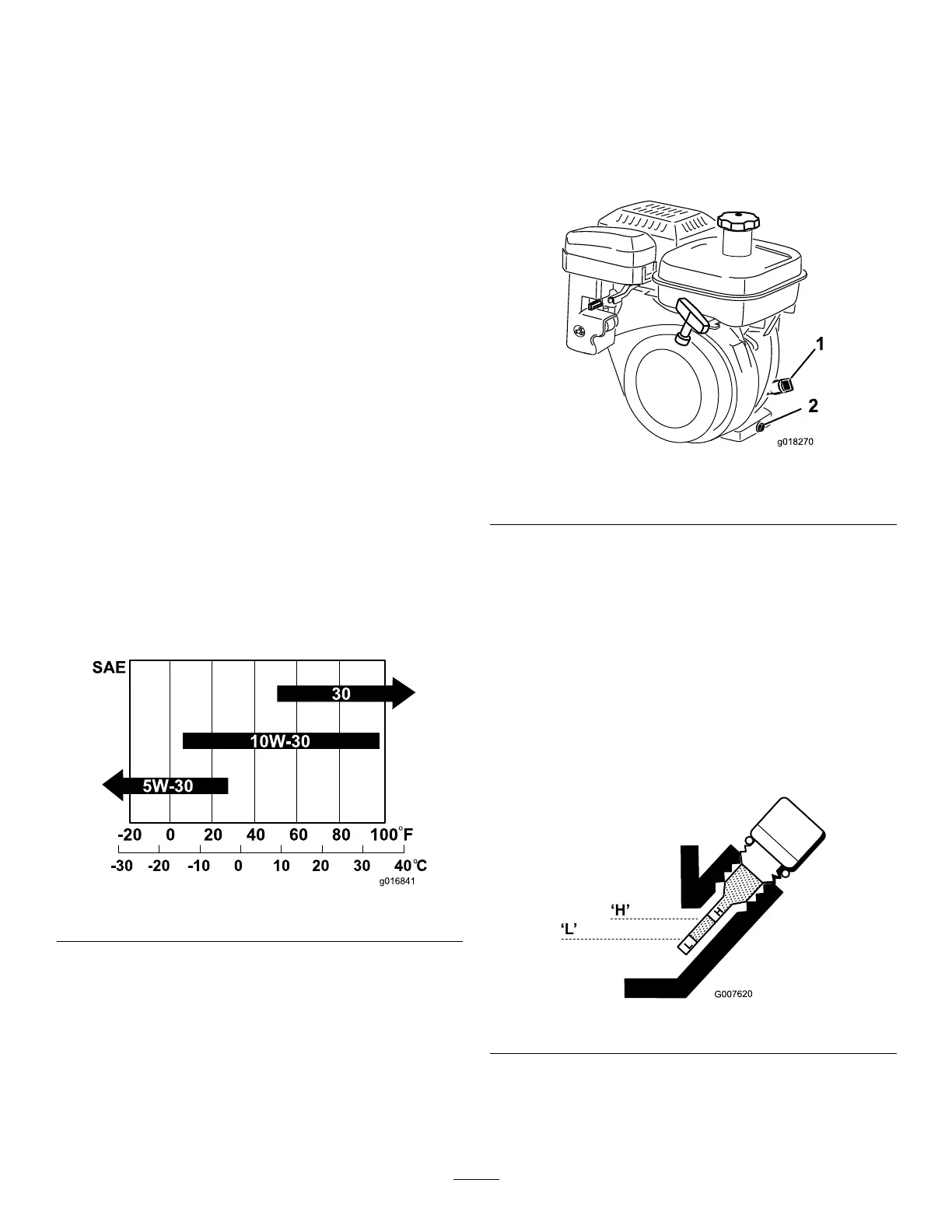

1.Removethetransportwheels(ifinstalled).

2.Positionthemachinesothattheengineislevel,

andcleantheareaaroundtheoil-levelgauge

(Figure34).

g018270

Figure34

1.Oil-leveldipstick

2.Drainplug

3.Removetheoil-leveldipstickbyrotatingit

counterclockwise(Figure34).

4.Wipethedipstickandinsertitintothellerport,

butdonotscrewthedipstickintotheport.

5.Removethedipstickandcheckthelevelofthe

oil.

6.Ifthelevelislow,addonlyenoughoiltoraise

theleveluntilitisbetweenthe“H”and“L”marks

onthedipstick(Figure35).Checkthelevelof

theoil.

Important:Donotoverllthecrankcase.

g007620

Figure35

7.Installthedipstickandwipeupanyoilthatmay

havespilled.

30

Loading...

Loading...