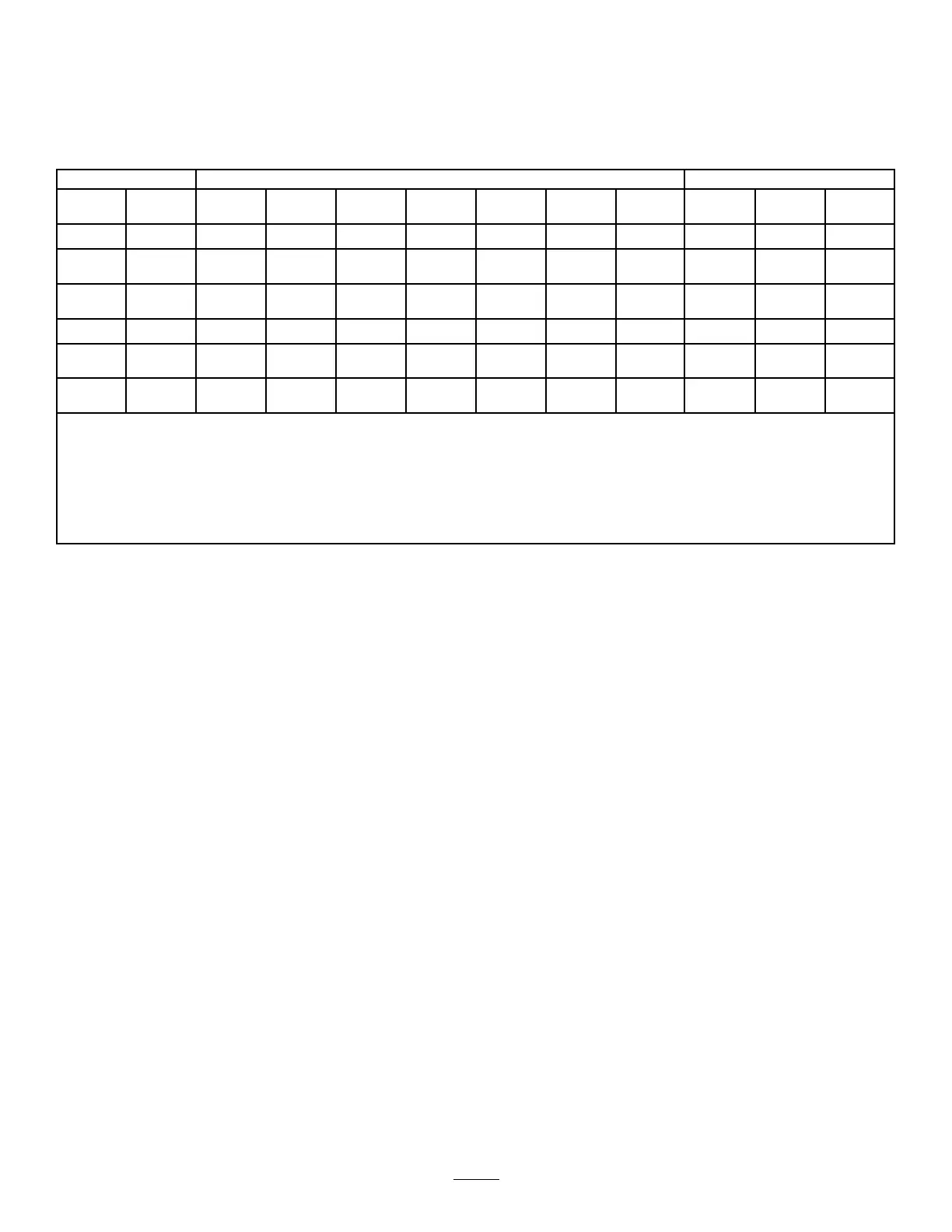

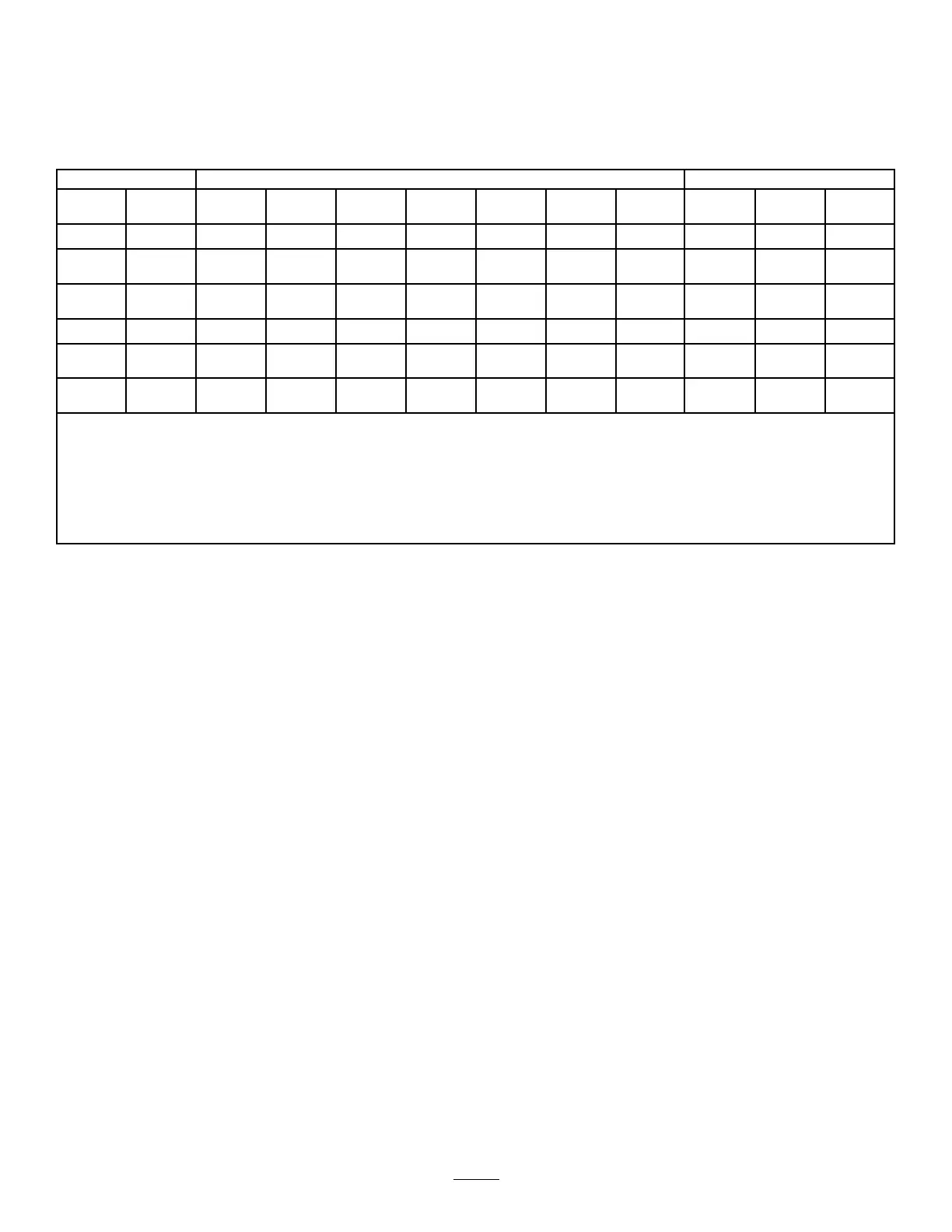

StandardControlModuleChart

Eachrowinthelogicchartbelowidentiesinputandoutputrequirementsforeachspecicproductfunction.

Theleftcolumnliststheproductfunctions.Thesymbolsidentifyspeciccircuitconditions,includingenergized

tovoltage,closedtoground,andopentoground.

SymbolsChartfortheStandardControlModule

Inputs

Outputs

FunctionPower

On

InNeutral

StartOnBrakeOnPTOOnInSeat

HiT emp

Shutdown

HiT emp

Warning

Start

ETR

PTO

Start

——

+

⊗⊗

—

⊗⊗

++

⊗

Run(Off

Unit)

——

⊗⊗⊗⊗⊗⊗⊗

+

⊗

Run(On

Unit)

—

⊗⊗

—

⊗

—

⊗⊗⊗

+

⊗

Mow

—

⊗⊗

———

⊗⊗⊗

++

HiT emp

Warning

—

⊗⊗

—(A)

++

⊗

HiT emp

Shutdown

—

⊗

—

⊗⊗⊗

(-)Indicatesacircuitclosedtoground.(LEDON)

(⊗)Indicatesacircuitopentogroundorde-energized(LEDOFF)

(+)Indicatesanenergizedcircuit(clutchcoil,solenoid,orstartinput)(LEDON)

ABlankindicatesacircuitthatisnotinvolvedwiththelogic.

(A)Re-initiatethePTOinputafterenginecooldown(cyclekeyon-off)

ServicingtheWireHarness

Preventcorrosionofwiringterminalsbyapplying

Grafo112X(Skin-over)grease,ToroPartNo.505-47,

totheinsideofallharnessconnectorswheneveryou

replacetheharness.

Important:Wheneverworkingwiththeelectrical

system,alwaysdisconnectthebatterycables,

negative(-)cablerst,topreventpossiblewiring

damagefromshort-outs.

DriveSystem

Maintenance

TorquingtheWheel-Lug

Nuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every200hours

Wheel-lugnuttorquespecication:102to108N∙m

(75to80ft-lb)

Torquethelugnutsatthefrontandrearwheels

inacrossingpatternasshowninFigure56tothe

speciedtorque.

50

Loading...

Loading...