Important:Bearingsrarelyfailfromdefectsin

materialsorworkmanship.Themostcommon

reasonforfailureismoistureandcontamination

workingitswaypasttheprotectiveseals.

Bearingsthataregreasedrelyuponregular

maintenancetopurgeharmfuldebrisfromthe

bearingarea.Sealedbearingsrelyonaninitial

llofspecialgreaseandarobustintegralsealto

keepcontaminantsandmoistureoutoftherolling

elements.

Thesealedbearingsrequirenolubricationorshort

termmaintenance.Useofsealedbearingsminimizes

routineserviceandreducesthepotentialturfdamage

fromgreasecontamination.Inspectofbearing

conditionandsealintegrityperiodicallytoavoid

downtime.Inspectthesealedbearingsseasonally

andreplacedthemiftheyaredamagedorworn.

Checkthatthebearingsdonotproducehighheat,

emitnoise,vibrateexcessively,orweeprust;the

bearingsshouldoperatesmoothly.

Duetotheoperatingconditionsthesebearing/seal

packagesaresubjectto(i.e.sand,turfchemicals,

water,impacts,etc.)theyareconsiderednormalwear

items.Bearingsthatfailduetootherthandefectsin

materialsorworkmanshiparetypicallynotcovered

underwarranty.

Note:Bearinglifecanbenegativelyaffectedby

improperwashingprocedures.Donotwashtheunit

whenitisstillhotandavoiddirectinghigh-pressureor

high-volumesprayatthebearings.

Newbearingscommonlypurgesomegreaseoutof

thesealsonanewmachine.Thispurgedgreaseturns

blackincolorduetocollectionofdebrisandnotdue

toexcessiveheat.Wipethisexcessgreasefromthe

sealsaftertheinitial8hours.Theareaaroundtheseal

lipmayalwaysappearwet.Thisisnotdetrimentalto

bearinglife,butkeepsthesealliplubricated.

Replacethecoringheadbearingeveryof500hours.

Abearingservicekitthatcoversthecompletecoring

headisavailablefromyourdistributor.

CheckingtheGearbox

Lubrication

ServiceInterval:Every100hours

Thegearboxislledwith80W-90gearoilor

equivalent.Allowthegearboxtocoolbeforechecking

thelubrication.

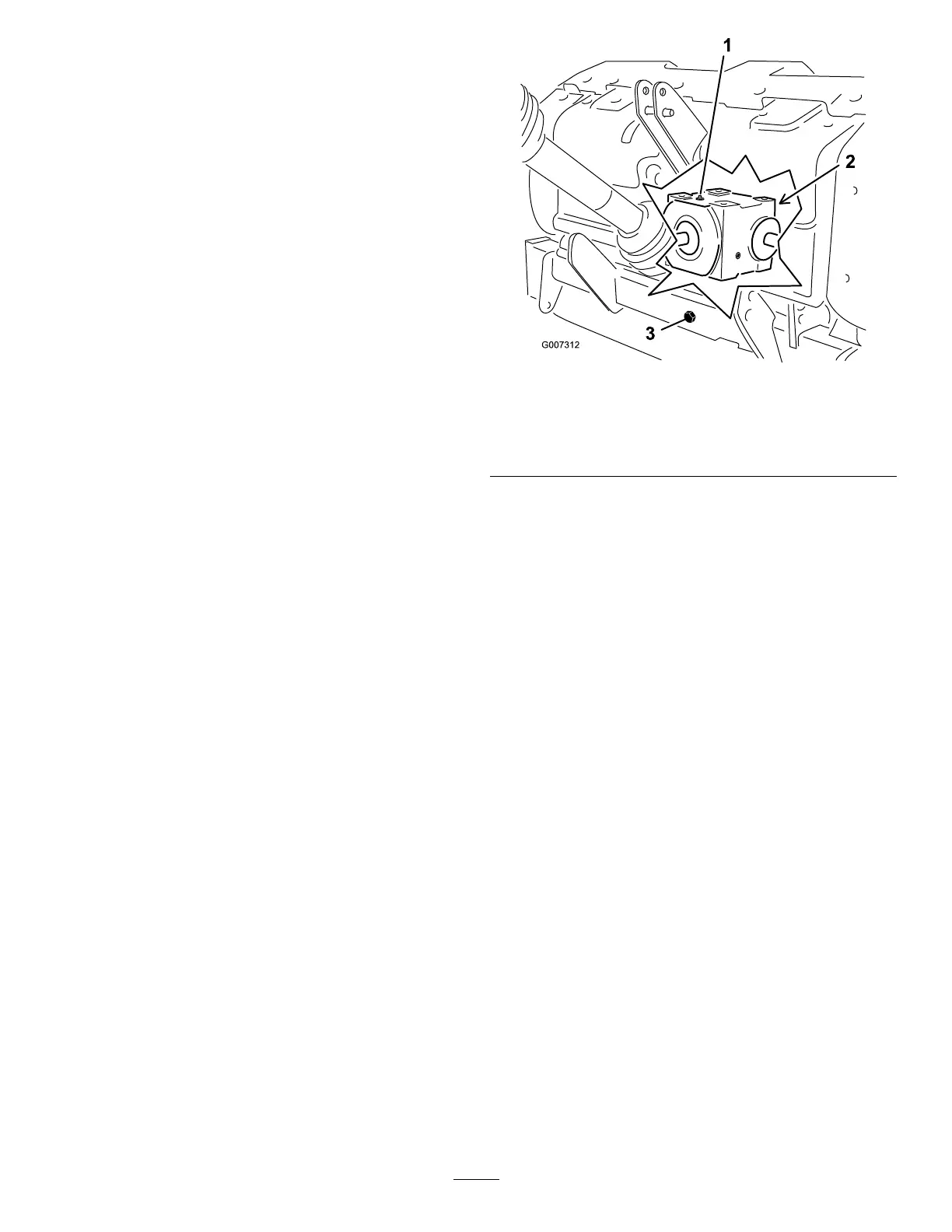

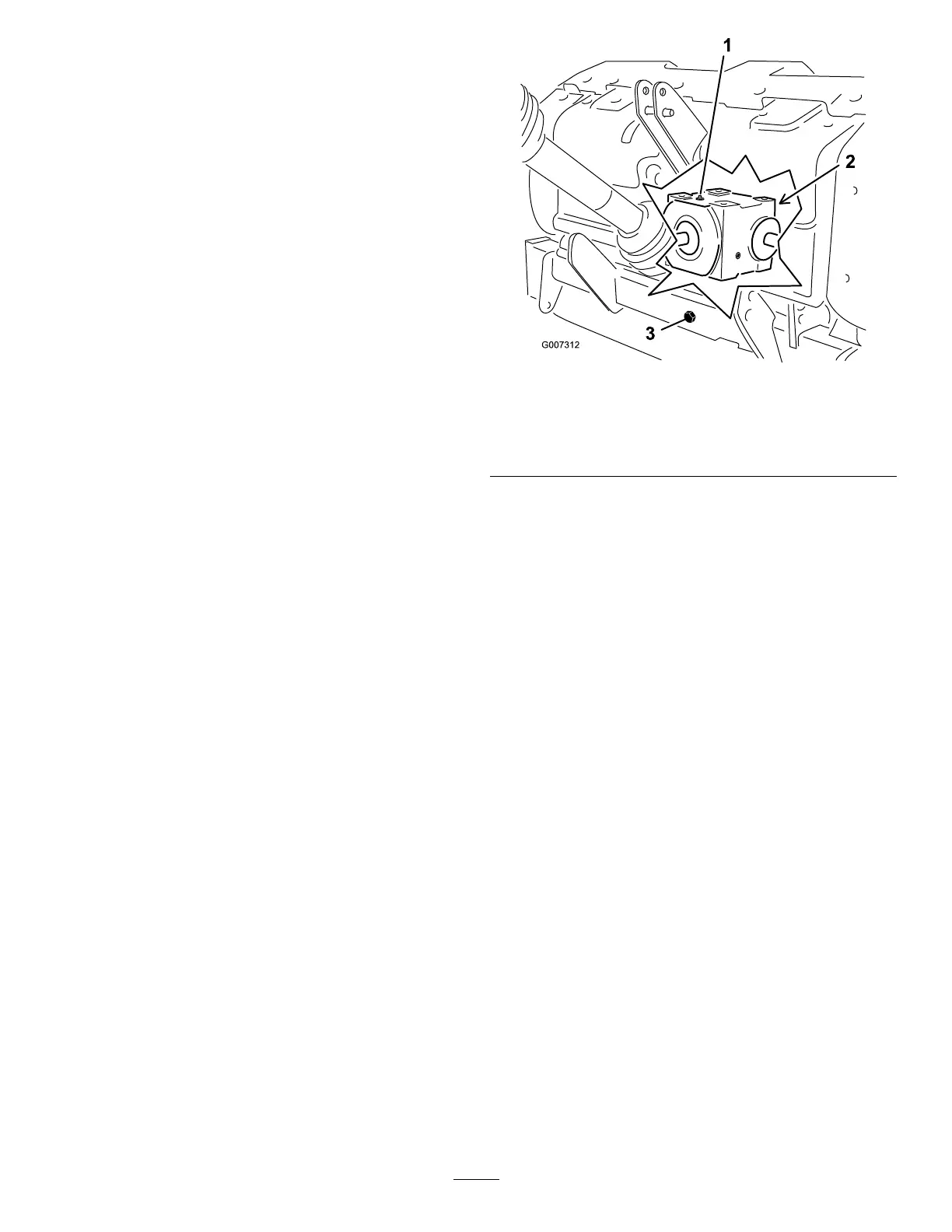

1.Cleandebrisfromthellplugandchecktheplug

toavoidcontamination.

2.Removethecheckplugfromthegearbox

(Figure30).

g007312

Figure30

1.Fillplug3.Drainplug

2.Checkplug(rearof

gearbox)

3.Makesurethattheoillevelisuptothebottomof

thecheckplugholeingearbox(Figure30).

4.Iftheoillevelislow,removethellplugfromthe

gearboxandaddoilasrequired.

5.Installtheplugs.

30

Loading...

Loading...