Primer Pump Reassembly (cont’d)

a. Gasket

“B”

has two sizes of fuel orifices

one large and one small.

Gasket

“A”

has one size of fuel orifices

both large.

b. Valve seat

“A”

has a locating notch that is

cut through the seat.

Valve seat

“B”

has a locating notch that is

partially cut into the seat.

c. Gasket

“A”

and valve seat

“A”

are inside

the pump. Gasket

“B”

and valve seat

“B”

are to the outside.

2.

Reassemble parts into the pump body. Posi-

tion gasket

B

so

the small fuel orifice is

toward the outlet nozzle of the pump body.

3. Place valve seat

A

with valve seats up, on

gasket

B.

4.

Push one valve cushion into valve seat

A

so

it

covers the double holed fuel orifice.

5.

Place gasket

A

on valve seat

A.

6.

Drop the two ball valves through gasket

A

to

seat in valve seat

A.

7.

Place one valve cushion into valve seat

B

so

8.

Set valve seat

8

with valve cushion into the

9.

Secure all parts by screwing the rubber

10. Reinstall the pump into the tank opening and

that it covers the double-holed fuel orifice.

pump body with assembled parts.

cap/button on the pump body.

attach the fuel line.

Fuel Pickup Tube and Filter Service

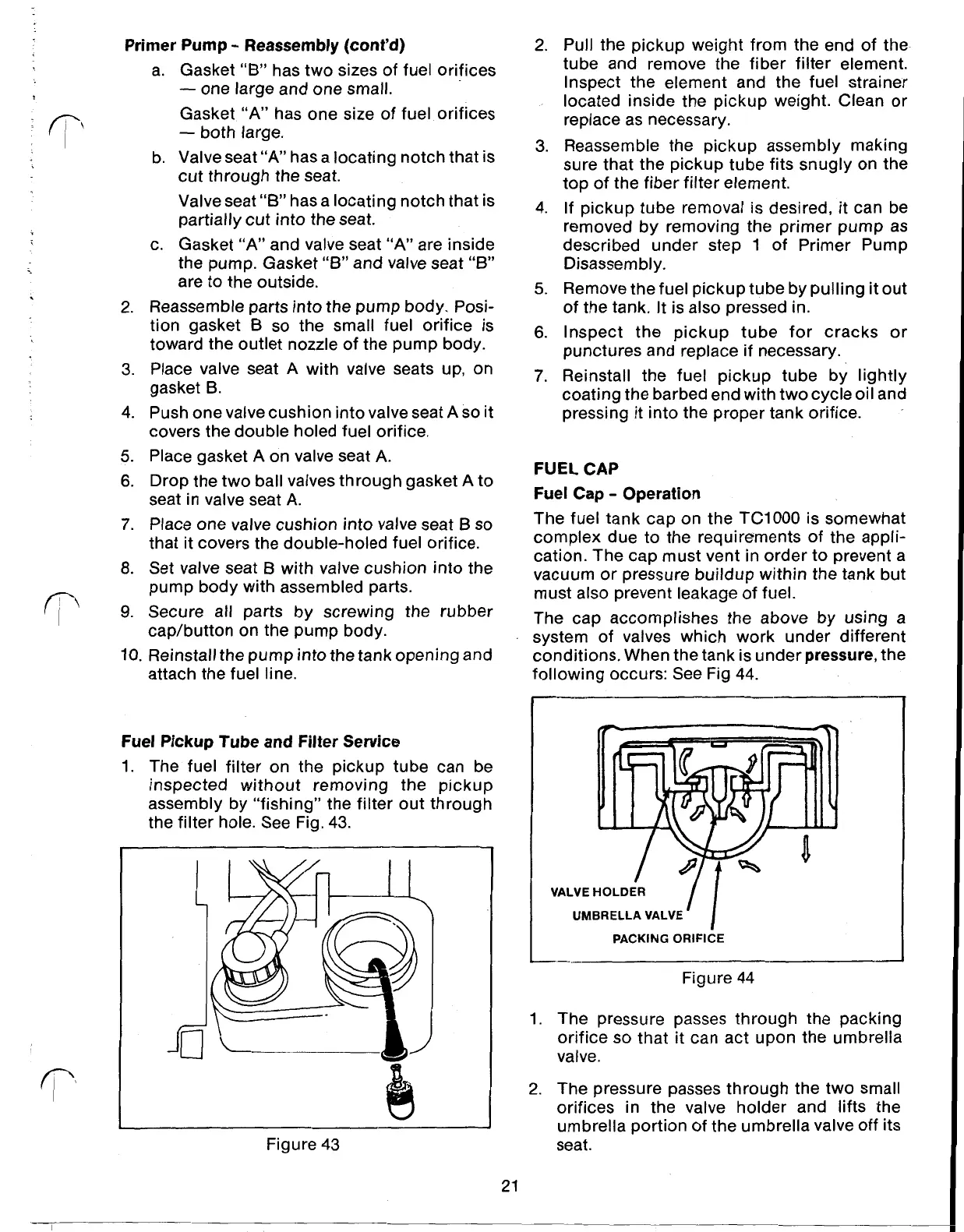

1. The fuel filter on the pickup tube can be

inspected without removing the pickup

assembly by “fishing” the filter out through

the filter hole. See Fig. 43.

Figure 43

2.

Pull the pickup weight from the end of the

tube and remove the fiber filter element.

Inspect the element and the fuel strainer

located inside the pickup weight. Clean or

replace as necessary.

3. Reassemble the pickup assembly making

sure that the pickup tube fits snugly on the

top of the fiber filter element.

4.

If pickup tube removal is desired, it can be

removed by removing the primer pump as

described under step of Primer Pump

Disassembly.

5.

Remove the fuel pickup tube by pulling it out

of the tank. It is also pressed in.

6.

Inspect the pickup tube for cracks or

punctures and replace

if

necessary.

7.

Reinstall the fuel pickup tube by lightly

coating the barbed end with two cycle oil and

pressing it into the proper tank orifice.

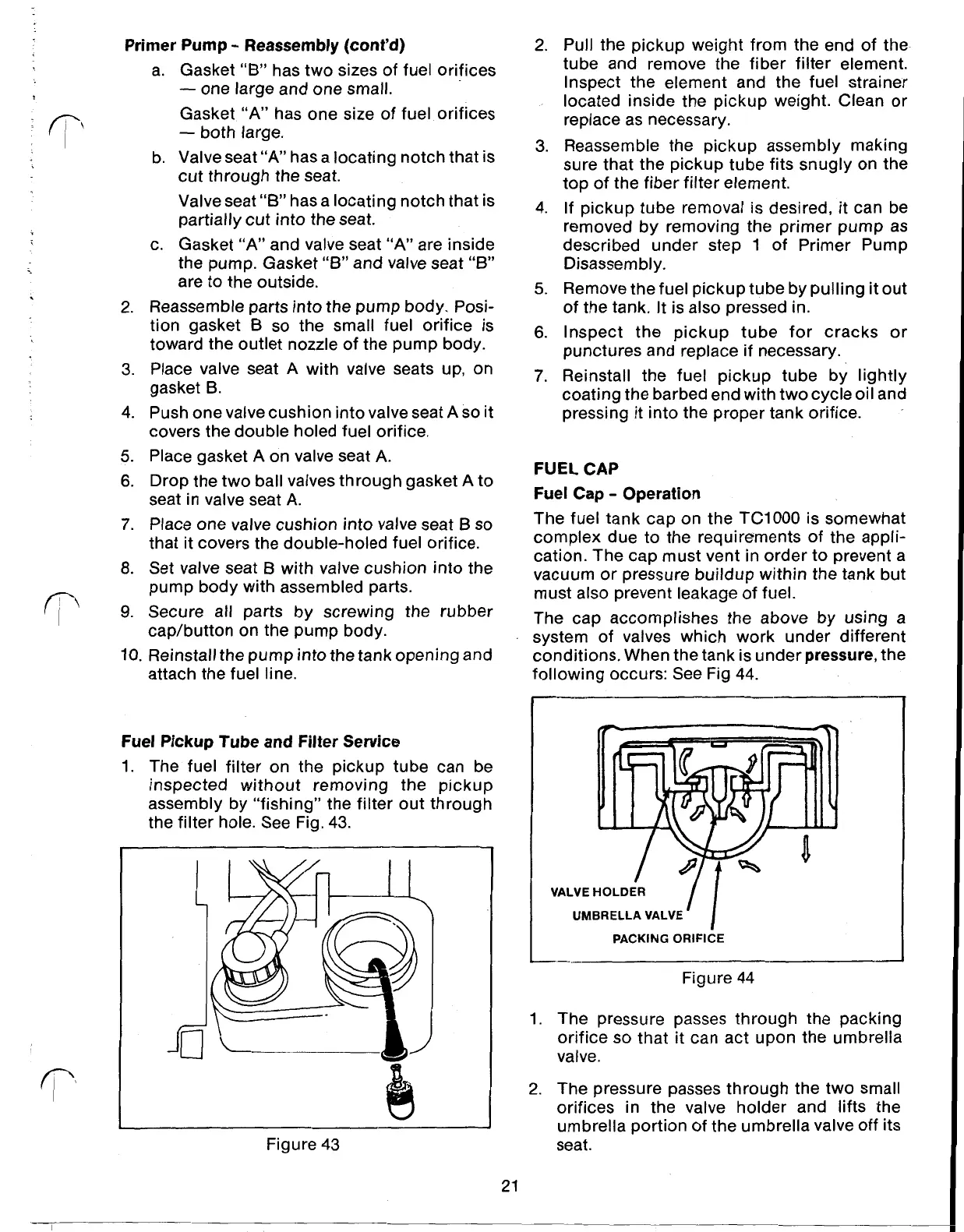

FUEL CAP

Fuel Cap Operation

The fuel tank cap on the TC1000 is somewhat

complex due to the requirements of the appli-

cation. The cap must vent in order to prevent a

vacuum or pressure buildup within the tank but

must also prevent leakage of fuel.

The cap accomplishes the above by using a

system of valves which work under different

conditions, When the tank is under

pressure,

the

following occurs: See Fig

44.

VALVE

HOLDER

UMBRELLA

VALVE

PACKING

ORIFICE

Figure 44

1. The pressure passes through the packing

orifice

so

that it can act upon the umbrella

valve

2.

The pressure passes through the two small

orifices in the valve holder and lifts the

umbrella portion of the umbrella valve

Off

its

seat.

21

Loading...

Loading...