SECTION

12

Drive Tube Removal

1.

Remove the engine as described under

Engine Removal from Drive Tube,

page

34.

2.

Remove the control as described under

Control and Grip Removal from Drive Tube,

page

40.

3.

Remove the handle as described under

Handle Removal from Drive Tube,

page

41.

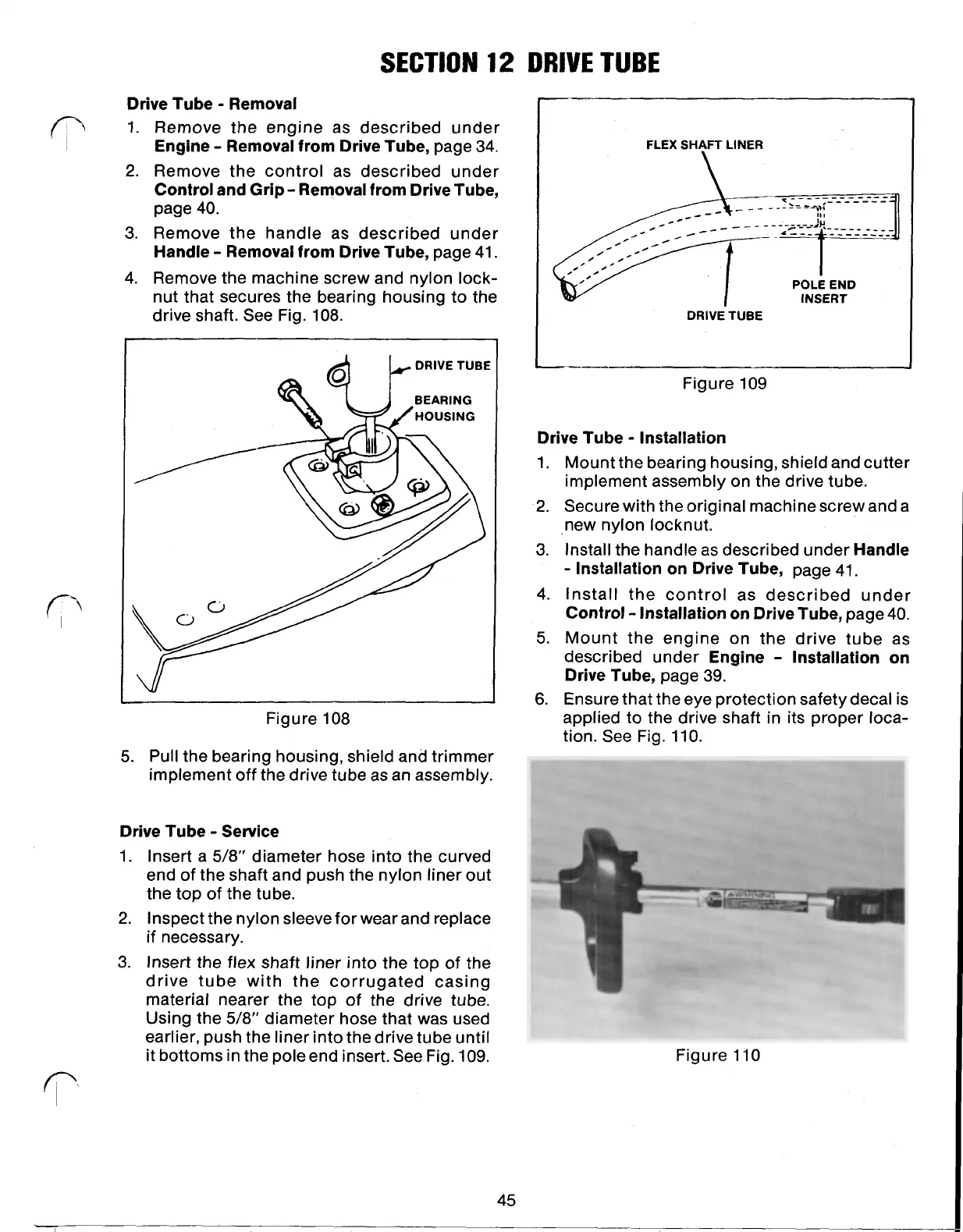

4.

Remove the machine screw and nylon lock-

nut that secures the bearing housing to the

drive shaft. See Fig.

108.

DRIVE TUBE

Figure

108

5.

Pull the bearing housing, shield and trimmer

implement off the drive tube as an assembly.

Drive Tube Service

1.

Insert a

5/8"

diameter hose into the curved

end of the shaft and push the nylon liner out

the top of the tube.

2.

Inspect the nylon sleeve for wear and replace

if

necessary.

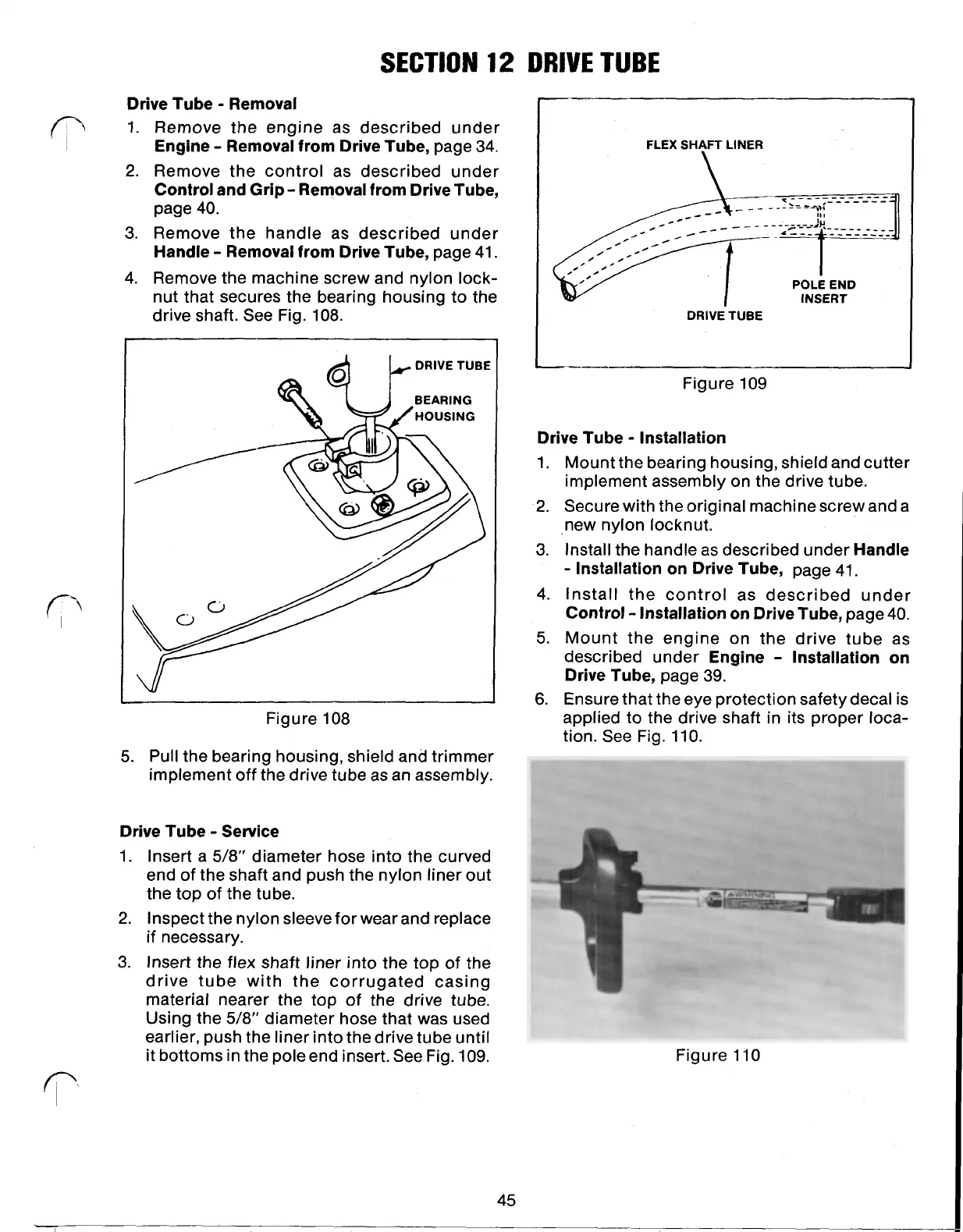

3.

Insert the flex shaft liner into the top of the

drive tube with the corrugated casing

material nearer the top of the drive tube.

Using the

5/8"

diameter hose that was used

earlier, push the liner into the drive tube until

it bottoms in the pole end insert. See Fig.

109.

45

DRIVE

TUBE

FLEX

SHAFT

LINER

POLE END

INSERT

DRIVE TUBE

-~--

Figure

109

Drive Tube Installation

1.

Mount the bearing housing, shield and cutter

implement assembly on the drive tube.

2.

Secure with the original machine screw and a

new nylon locknut.

3.

Install the handle as described under

Handle

Installation on Drive Tube,

page

41.

4.

Install the control as described under

Control Installation on Drive Tube,

page

40.

5.

Mount the engine on the drive tube as

described under

Engine Installation on

Drive Tube,

page

39.

6.

Ensure that the eye protection safety decal is

applied to the drive shaft in its proper loca-

tion. See Fig.

l

10.

Figure

110

Loading...

Loading...