Clutch Shoes and Flywheel

-

Operation

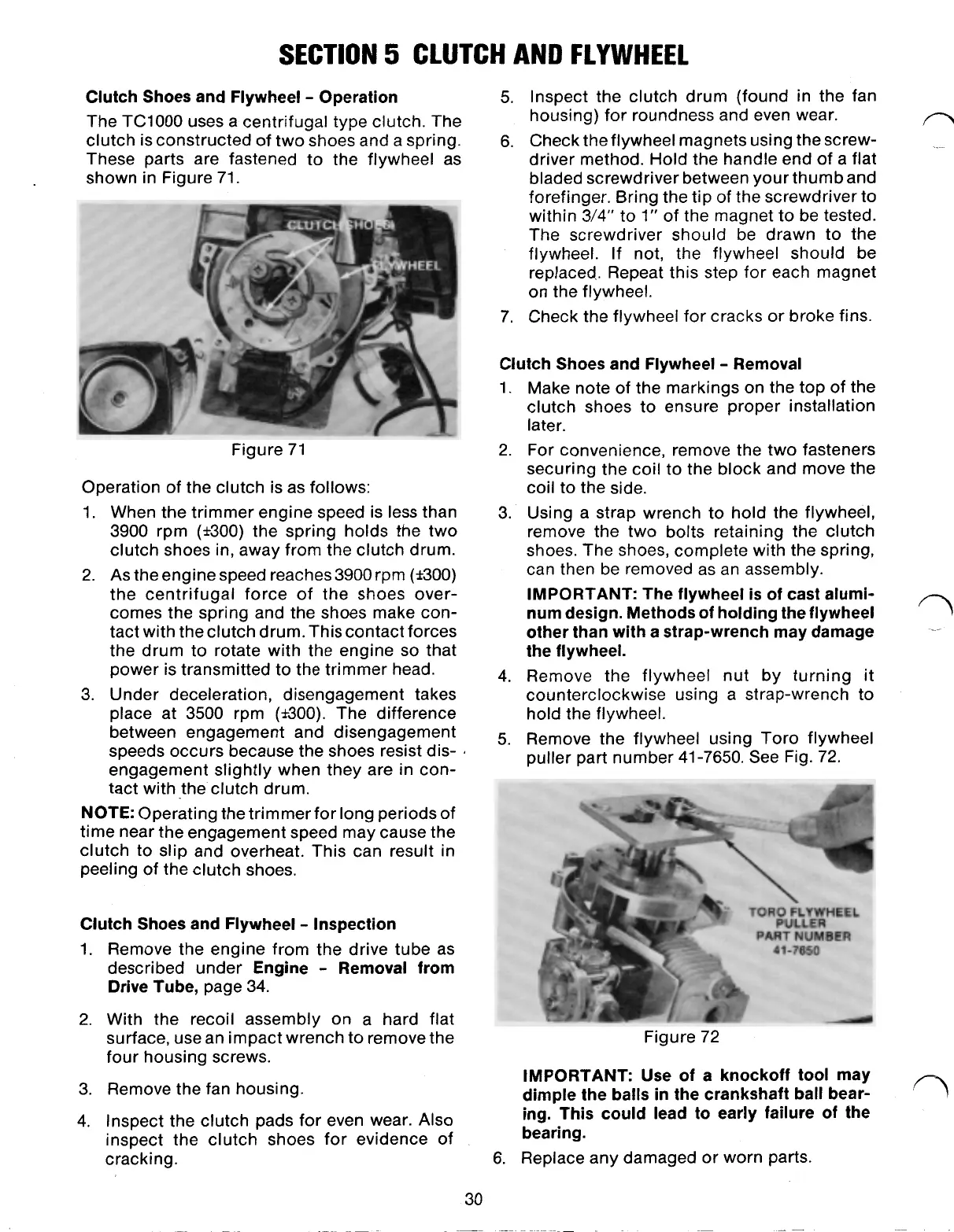

The TClOOO uses a centrifugal type clutch. The

clutch is constructed of two shoes and a spring.

These parts are fastened to the flywheel as

shown in Figure 71.

Figure 71

Operation of the clutch is as follows:

1. When the trimmer engine speed is less than

3900

rpm the spring holds the two

clutch shoes in, away from the clutch drum.

2.

As

the engine speed reaches

3900

rpm

the centrifugal force of the shoes over-

comes the spring and the shoes make con-

tact with the clutch drum. This contact forces

the drum to rotate with the engine

so

that

power is transmitted to the trimmer head.

3. Under deceleration, disengagement takes

place at 3500 rpm The difference

between engagement and disengagement

speeds occurs because the shoes resist dis-

engagement slightly when they are in con-

tact with the clutch drum.

NOTE:

Operating the trimmer for long periods of

time near the engagement speed may cause the

clutch to slip and overheat. This can result in

peeling of the clutch shoes.

Clutch Shoes and Flywheel

-

Inspection

1. Remove the engine from the drive tube as

described under

Engine

-

Removal from

Drive Tube,

page 34.

2. With the recoil assembly on a hard flat

surface, use an impact wrench to remove the

four housing screws.

3.

Remove the fan housing.

4. Inspect the clutch pads for even wear.

Also

inspect the clutch shoes for evidence of

cracking.

5.

Inspect the clutch drum (found in the fan

housing) for roundness and even wear.

6.

Check the flywheel magnets using the screw-

driver method. Hold the handle end of a flat

bladed screwdriver between your thumb and

forefinger. Bring the tip of the screwdriver to

within

3/4"

to 1" of the magnet to be tested.

The screwdriver should be drawn to the

flywheel. If not, the flywheel should be

replaced.. Repeat this step for each magnet

on the flywheel.

7. Check the flywheel for cracks or broke fins.

Clutch Shoes and Flywheel

-

Removal

Make note of the markings on the top of the

clutch shoes to ensure proper installation

later.

For convenience, remove the two fasteners

securing the coil to the block and move the

coil to the side.

Using a strap wrench to hold the flywheel,

remove the two bolts retaining the clutch

shoes. The shoes, complete with the spring,

can then be removed as an assembly.

IMPORTANT: The flywheel

is

of cast alumi-

num design. Methods of holding the flywheel

other than with a strap-wrench may damage

the flywheel.

Remove the flywheel nut by turning it

counterclockwise using a strap-wrench to

hold the flywheel.

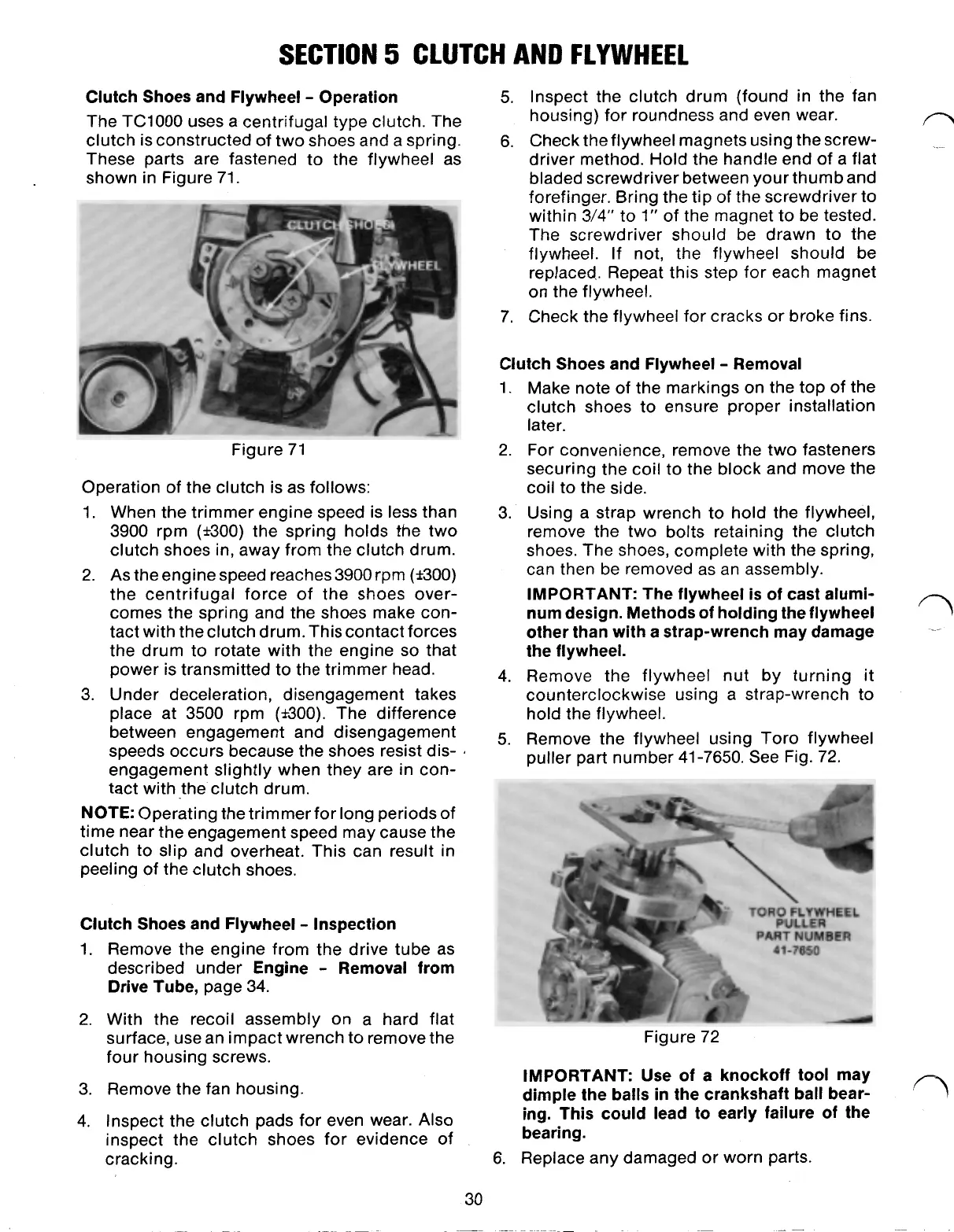

Remove the flywheel using Toro flywheel

puller part number 41-7650. See Fig. 72.

TORO

FLYWHEEL

PULLER

PART

NUMBER

41-7650

Figure 72

IMPORTANT: Use of a knockoff tool may

dimple the balls in the crankshaft ball bear-

ing. This could lead to early failure of the

bearing.

Replace any damaged or worn parts.

30

Loading...

Loading...