EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

aircleanerfordirty,looseordamaged

parts.

Thisengineisequippedwithareplaceable,highdensity

paperaircleanerelement.Checktheaircleanerdailyor

beforestartingtheengine.Checkforabuildupofdirt

anddebrisaroundtheaircleanersystem.Keepthisarea

clean.Alsocheckforlooseordamagedcomponents.

Replaceallbentordamagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamagedair

cleanercomponentscouldallowunlteredairintothe

enginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

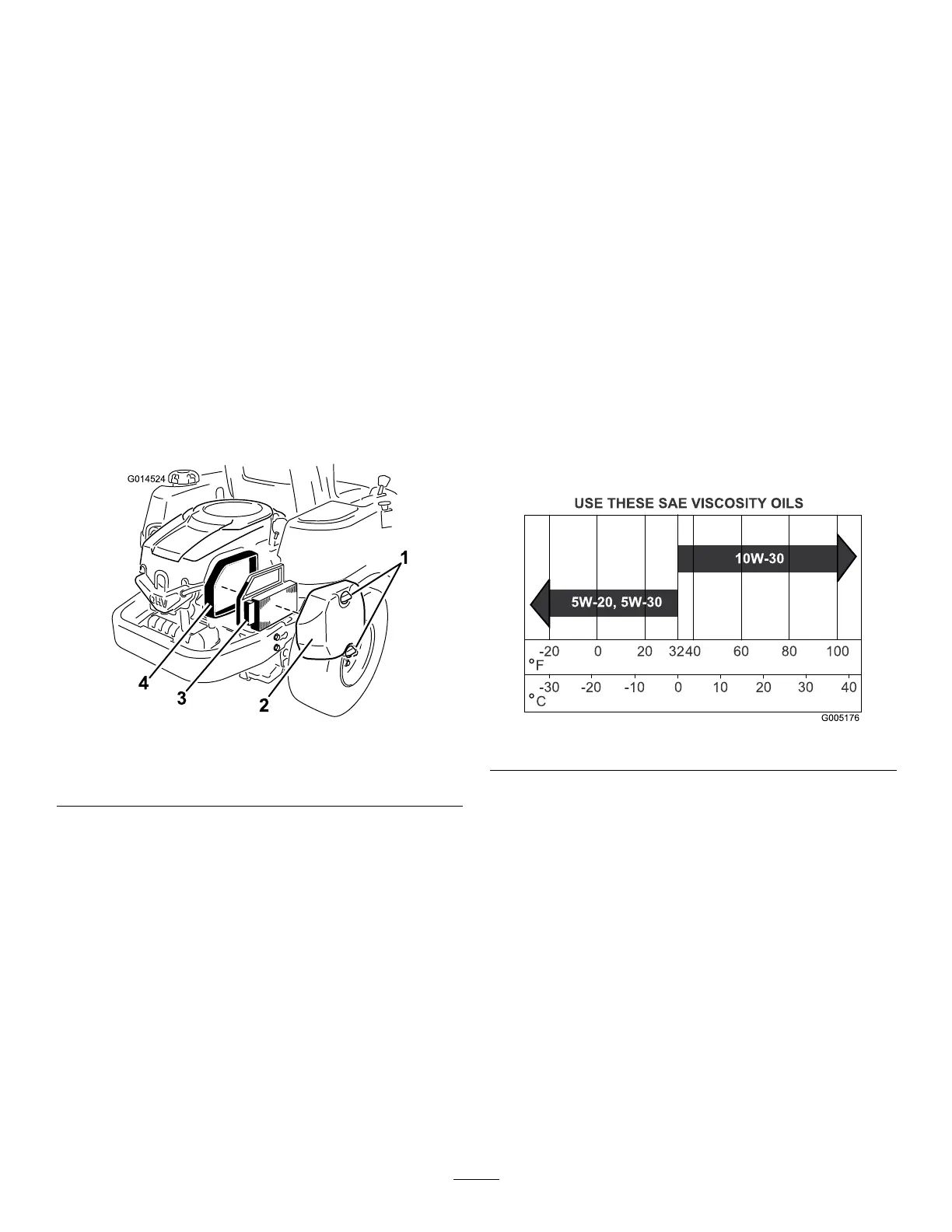

Figure26

1.Knobs,aircleanercover3.Paperelement

2.Aircleanercover4.Aircleanerbase

ServicingPaperElement

ServiceInterval:Every25hours—Servicethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

Every100hours—Replacethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

1.Removetheaircleanercover(

Figure26).

2.Removetheaircleanerelementwiththeintegral

rubberseal(

Figure26).

3.Gentlytapthepleatedsideofthepaperelementto

dislodgedirt.Donotwashthepaperelementor

usepressurizedair,asthiswilldamagetheelement.

Replaceadirty,bent,ordamagedelement.Handle

newelementscarefully;donotuseiftherubberseal

isdamaged.

4.Cleanallaircleanercomponentsofanyaccumulated

dirtorforeignmaterial.Preventanydirtfrom

enteringthecarburetor.

5.Installtheaircleanerelementwiththepleatedside

“out”andseattherubbersealontotheedgesofthe

aircleanerbase(

Figure26).

6.Reinstalltheaircleanercoverandsecurewiththe

twoknobs(

Figure26).

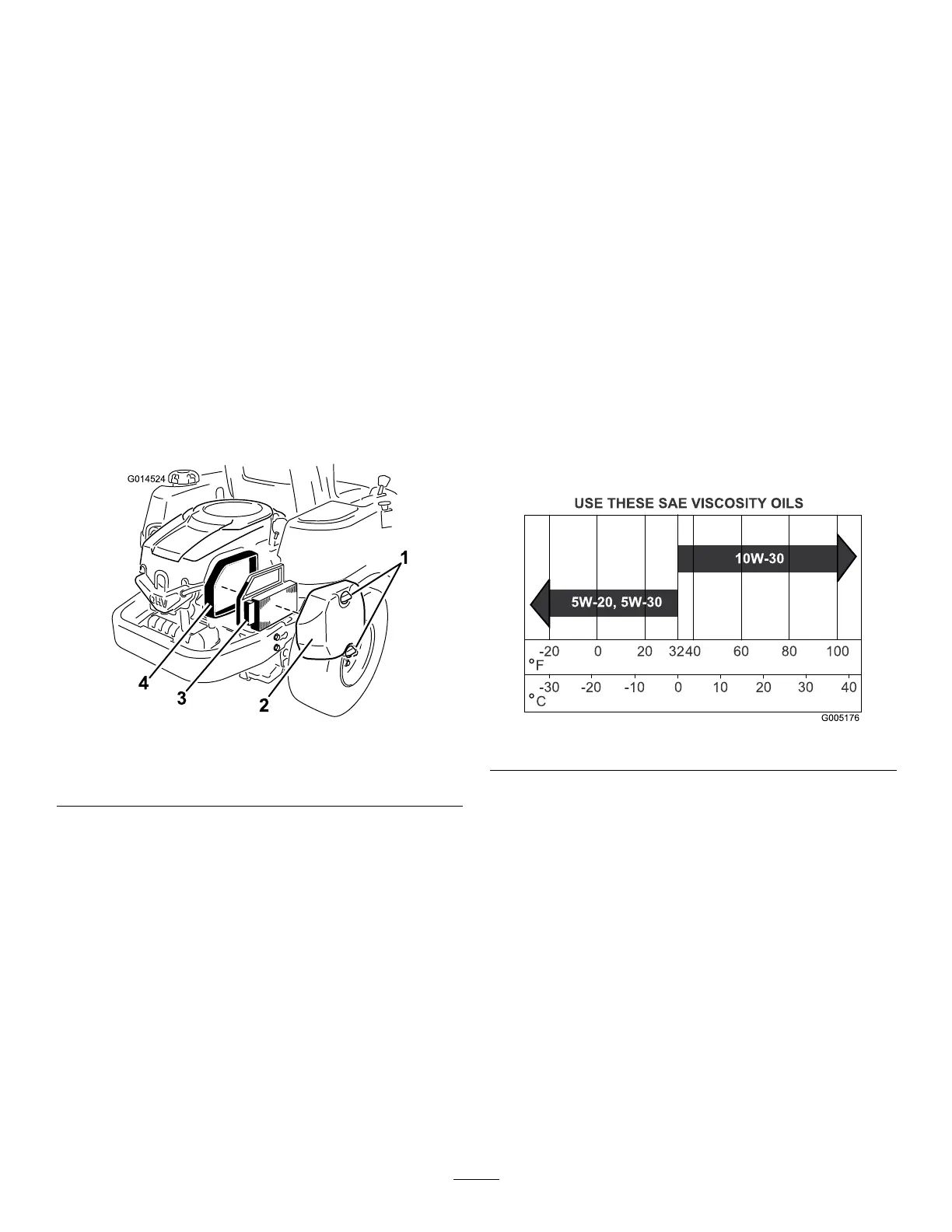

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,or

higher)

CrankcaseCapacity:51ounces(1.5l)whenthelter

ischanged

Viscosity:Seethetablebelow.

Figure27

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,andremove

thekey.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Pullandremovetheoilllcap/dipstick;wipeoil

off.Reinsertthedipstickandpushrmlyintoplace

(

Figure28).

25

Loading...

Loading...