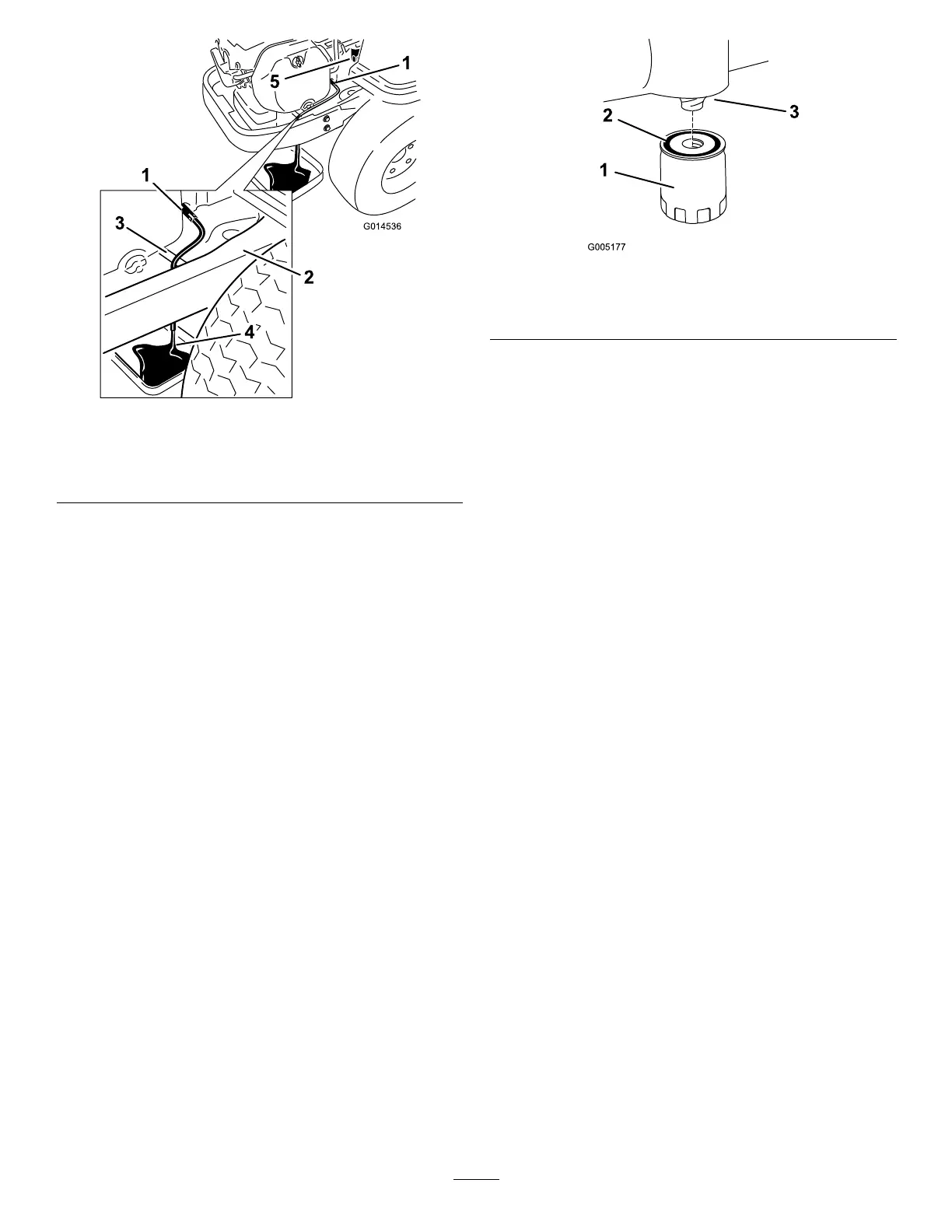

Figure30

1.Oildrainvalve

4.Pan

2.Machineframe5.Oillter

3.Oildrainhose

7.Turnthedrainvalve1/4counterclockwisetoopen

andallowtheoiltodrain(

Figure30).Removetheoil

llcap/dipstick(

Figure28).

8.Besuretoallowampletimeforcompletedrainage.

9.Removetheoldlterandwipeoffthemountingpad

(

Figure30).

10.Whenoilhasdrainedcompletely,closetheoildrain

valve.Removetheoildrainhoseandwipeupany

excessoilontheframe(

Figure30).

Note:Disposeoftheusedoilatarecyclingcenter.

11.Placethenewreplacementlterinashallowpan

withtheopenendup.Pournewoiloftheproper

type,inthroughthethreadedcenterhole.Stop

pouringwhentheoilreachesthebottomofthe

threads.Allowaminuteortwofortheoiltobe

absorbedbytheltermaterial.

12.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

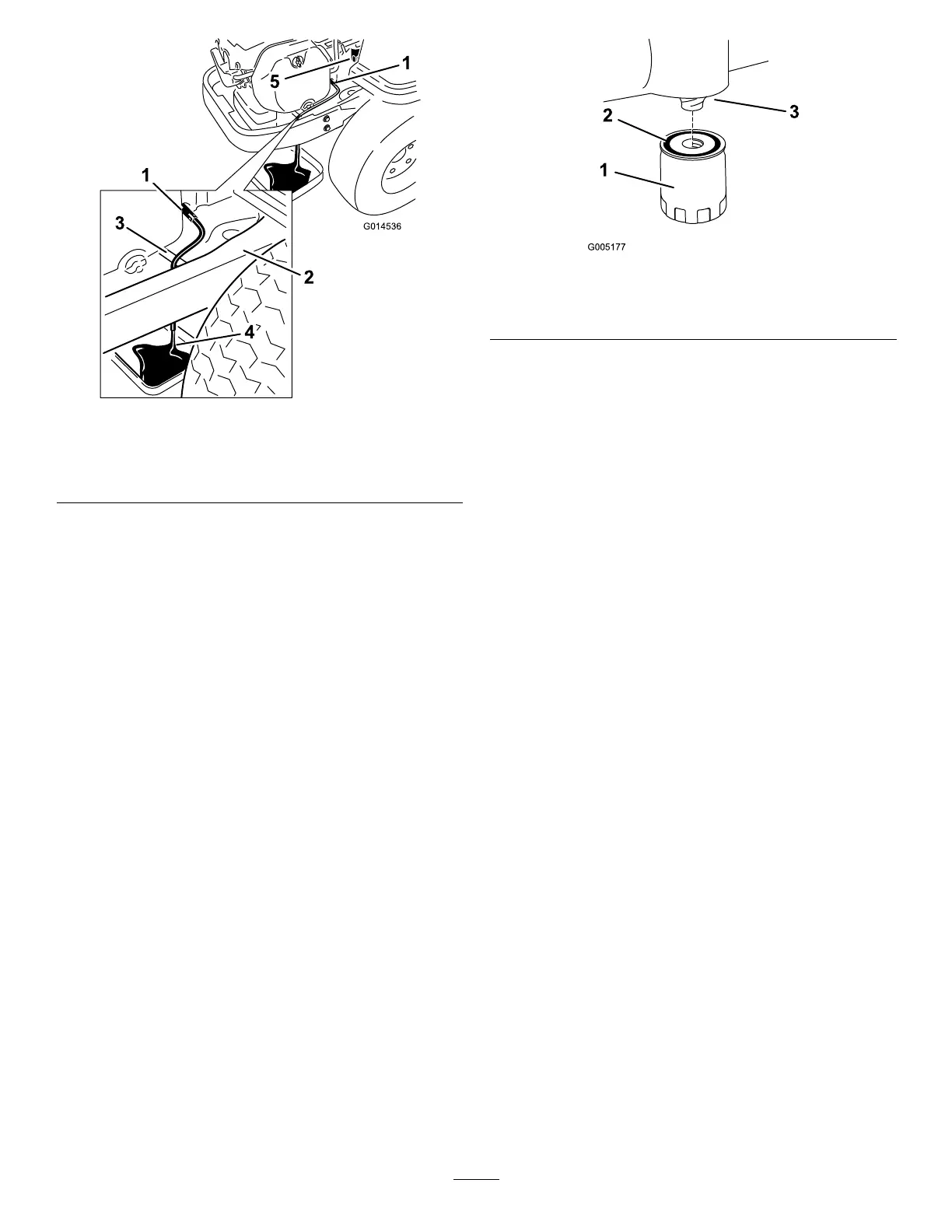

13.Installthereplacementoilltertothemountingpad.

Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

2/3to1turn(

Figure31).

Figure31

1.Oillter

3.Adapter

2.Gasket

14.Slowlypourapproximately80%ofthespeciedoil

intothellertube(

Figure28).

15.Installtheoilllcap/dipstickandpushrmlyinto

place(

Figure28).

16.Checktheoillevel(

Figure28);refertoChecking

theOilLevel.

17.Slowlyaddadditionaloiltobringittothefullmark.

18.Installtheoilllcap/dipstickandpushrmlyinto

place(

Figure28).

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checksparkplug

conditionandgap.

Every500hours—Replacethespark

plug.

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.Sparkplugreplacementis

recommendedat500hours.

Type:ChampionXC12YC(orequivalent)

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,stop

theengine,andremovethekey.

2.Pullthewireoffofthesparkplug(

Figure32).Clean

aroundthesparkplugtopreventdirtfromfalling

intotheengineandpotentiallycausingdamage.

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

3.Removethesparkplugandmetalwasher.

27

Loading...

Loading...