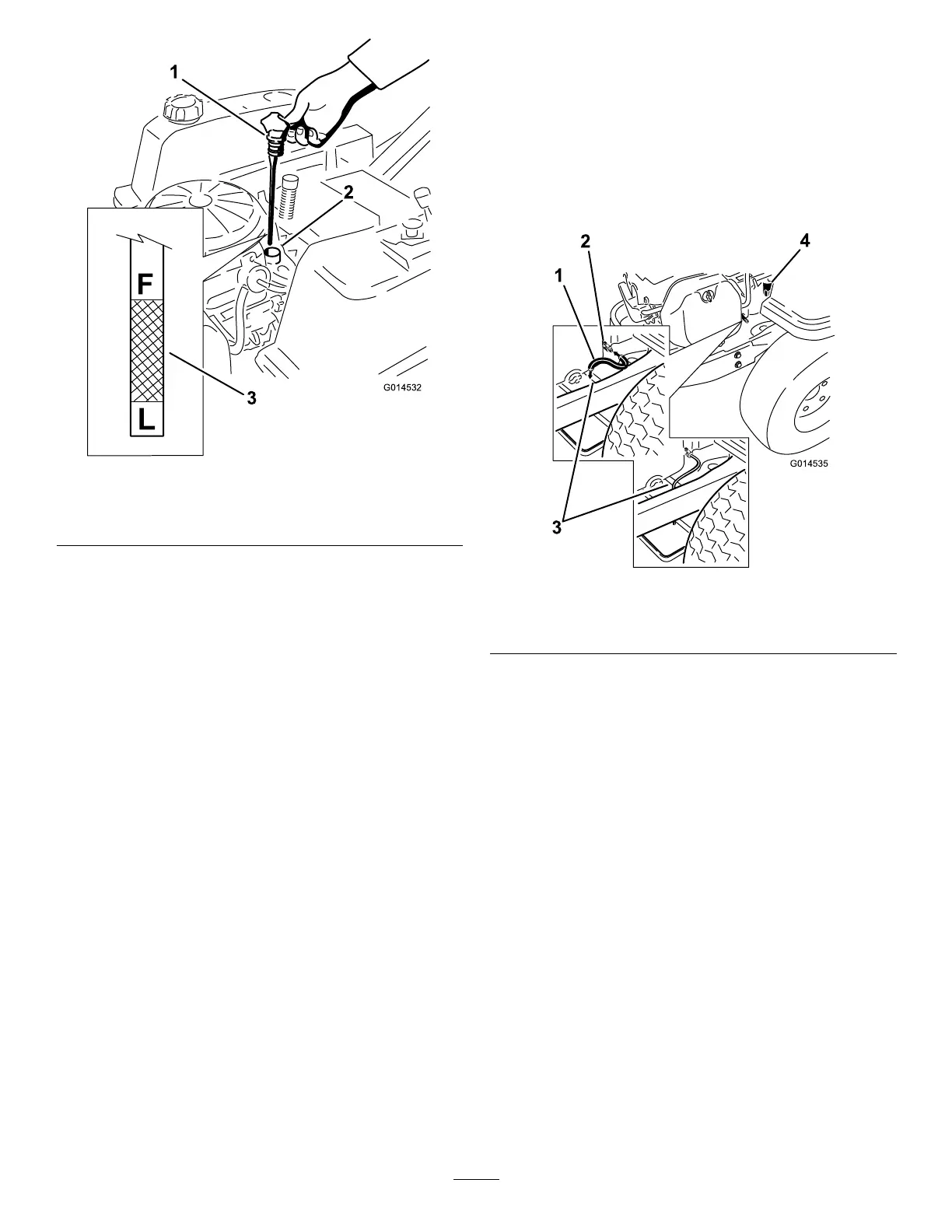

Figure28

1.Oildipstick3.Oillevel

2.Fillertube

5.Removethedipstickandchecktheoillevel.

(

Figure28).

Theoillevelshouldbeupto,butnotover,theF

markonthedipstick.

6.Ifthelevelislow,addoilofthepropertype,upto

theFmarkonthedipstick.Alwayscheckthelevel

withthedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

“L”markoroverthe“F”markonthedipstick.

ChangingtheOilandtheFilter

ServiceInterval:Every100hours—Changetheengine

oilandlter.

RellwithserviceclassSG,SH,SJorhigheroilas

speciedinthe“ViscosityGrades”table.

Changetheoilandlterwhiletheengineisstillwarm.

Theoilwillowmorefreelyandcarryawaymore

impurities.Makesuretheengineislevelwhenlling,

checking,orchangingtheoil.

Changetheoilandoillterasfollows:

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheparkposition.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleantheareaaroundthedrainvalveandonthe

machineframe.Locatetheoildrainhoseandslide

itoverthedrainvalve(

Figure29).

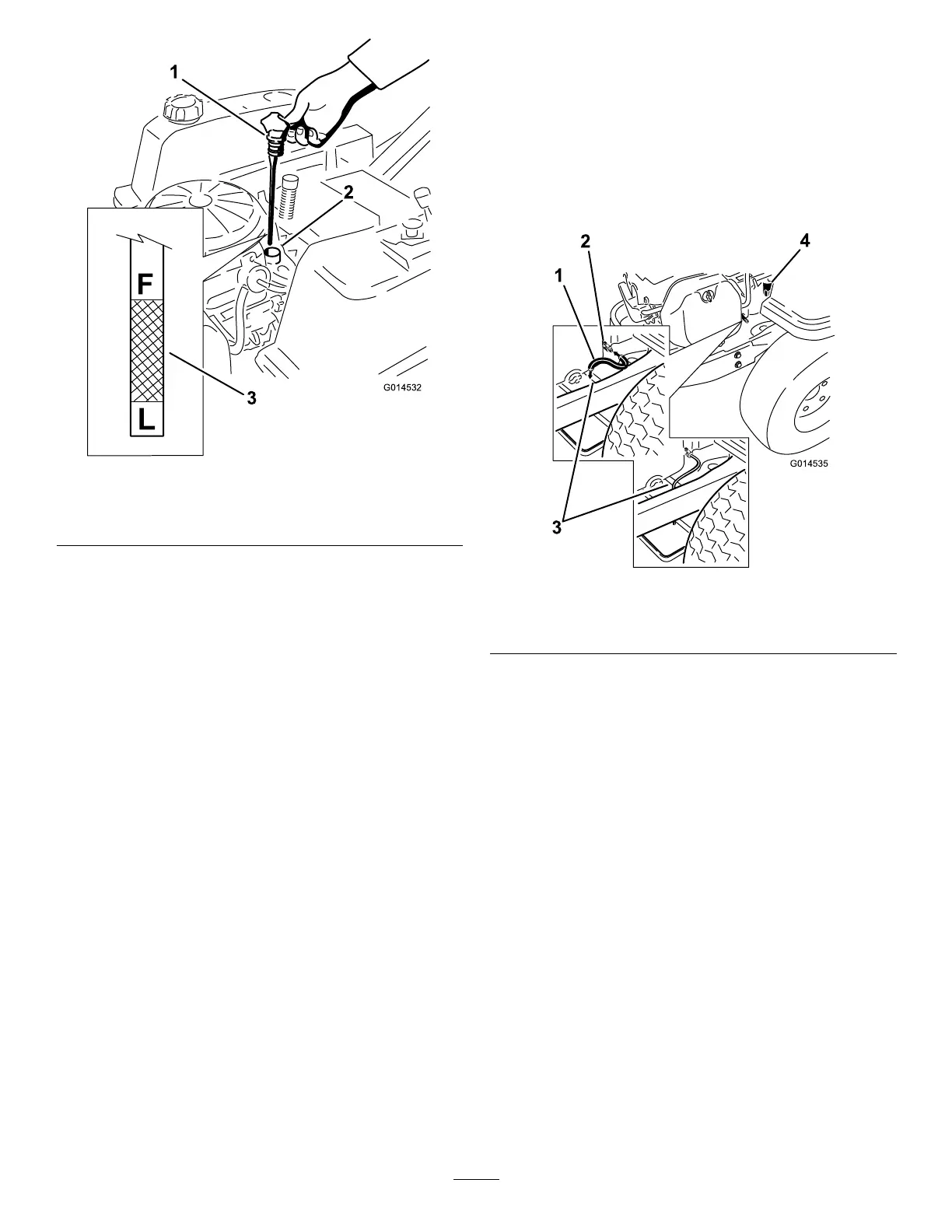

Figure29

1.Oildrainhose3.Endofframe

2.Drainvalve

4.Oillter

5.Placetheoppositeendoftheoildrainhoseoverthe

endoftheframe(

Figure29).

6.Placeapanunderneathmachinedirectlybelowthe

drainhoseasshowninFigure30.

26

Loading...

Loading...