RemovingtheSeat

Assembly

1.Pushtheseatassemblyforwardtotheraised

position(Figure26).

2.Slidetheseatassemblytothesideoutofthe

pins,andlifttheseatassemblyupward(Figure

27).

g190187

Figure27

1.Pins

InstallingtheSeat

Assembly

Slidetheseatassemblyontothepinsandlowerthe

seatassembly(Figure28).

g190186

Figure28

1.Pins

Lubrication

GreasingtheMachine

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Greasethebearings

andbushings.Greasethemachine

morefrequentlywhenusingitfor

heavy-dutyoperations.

GreaseType:No.2lithiumgrease

1.Usearagtowipethegreasettingcleansothat

foreignmattercannotbeforcedintothebearing

orbushing.

2.Withagreasegun,apply1or2pumpsofgrease

intothegreasettingsonthemachine.

3.Wipetheexcessgreaseoffthemachine.

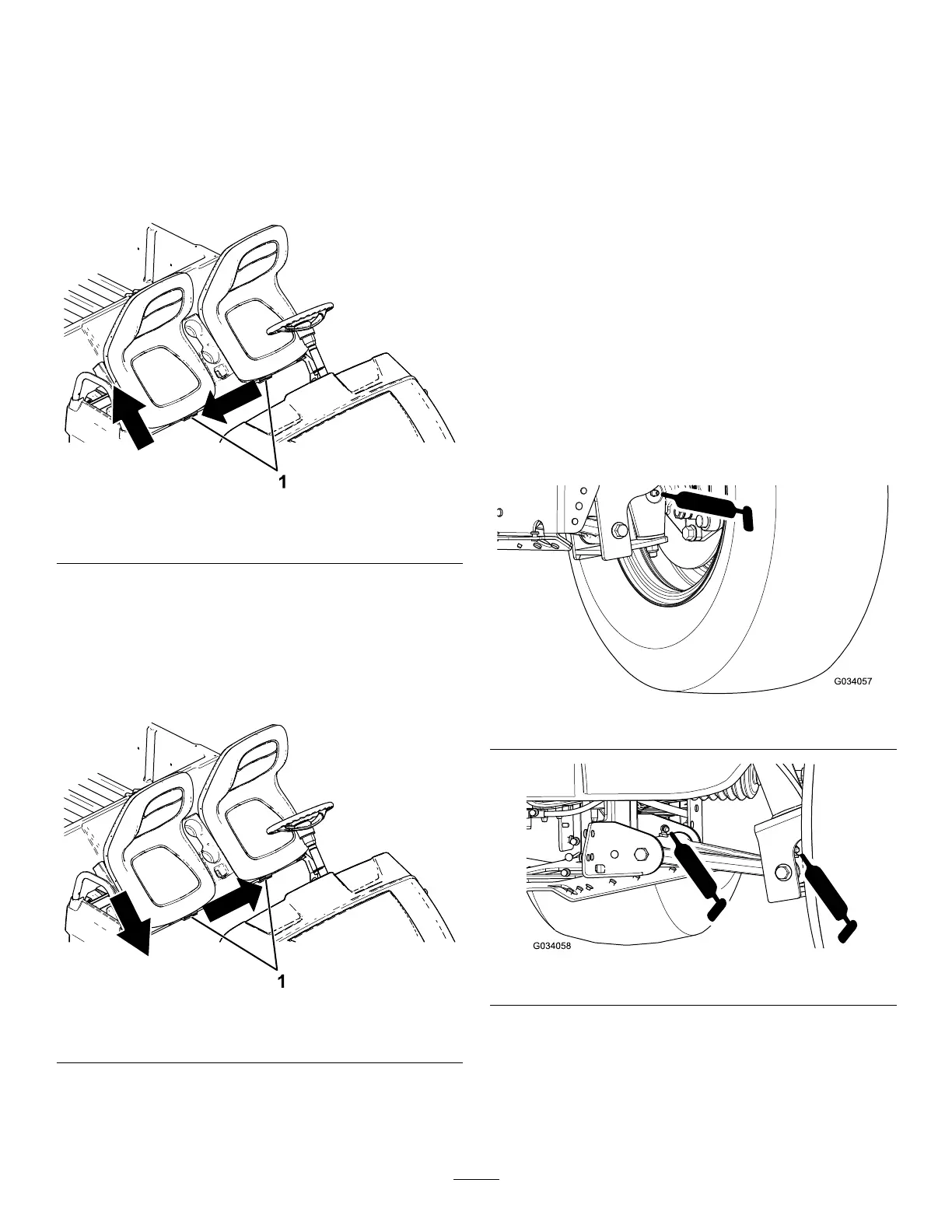

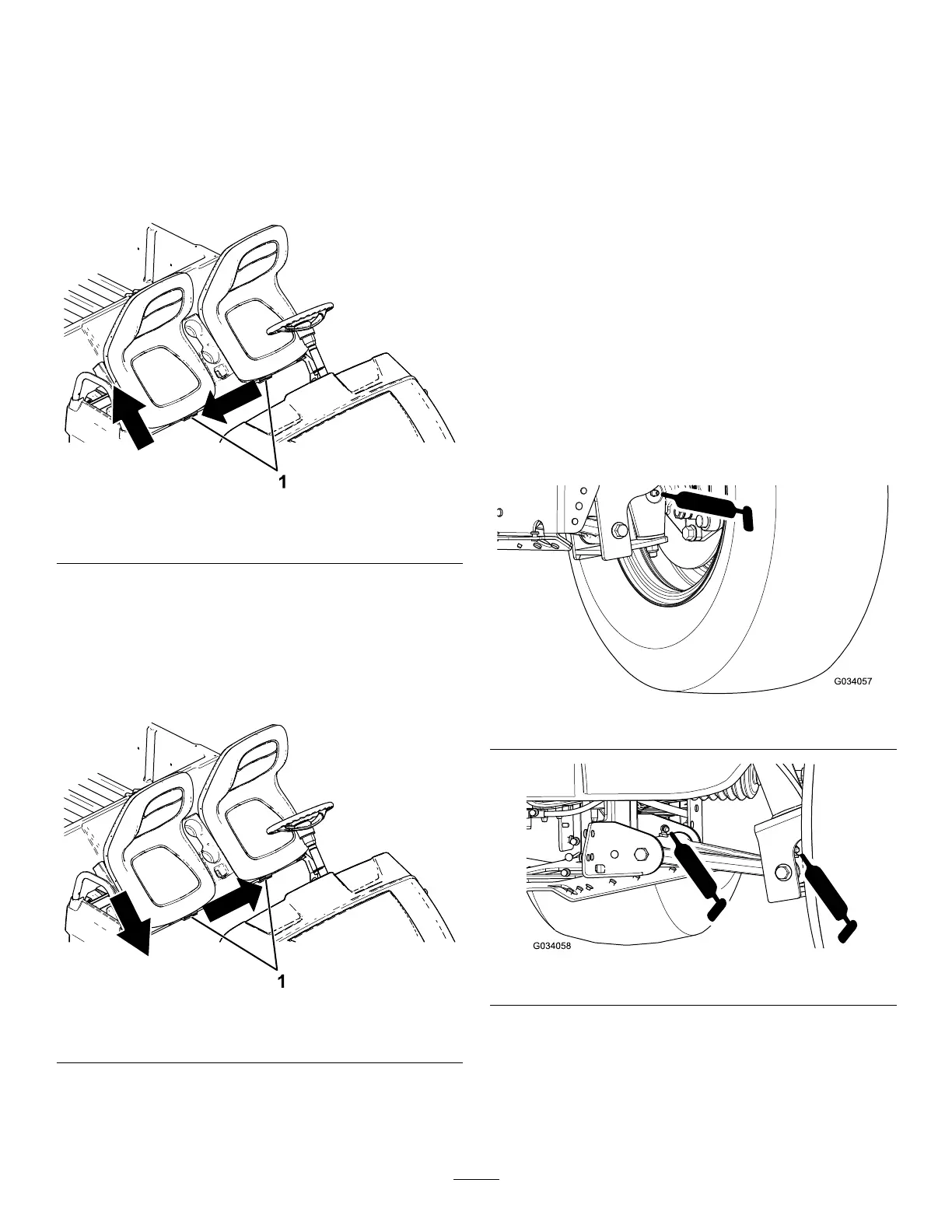

Thegreasettingsarelocatedattheinnerendofthe

controlarms,thetie-rodballjoint,andtheouterend

ofthecontrolarms(Figure29andFigure30).

g034057

Figure29

g034058

Figure30

34

Loading...

Loading...