,167$//$7,21

&RS\ULJKW7UDFH(QJLQHHULQJ&R,QF 7HOHSKRQH 3DUW1XPEHU

WK

6WUHHW1( )D[ 2FWREHU

$UOLQJWRQ:$86$ ZZZWUDFHHQJLQHHULQJFRP 3DJH

DC Conductors

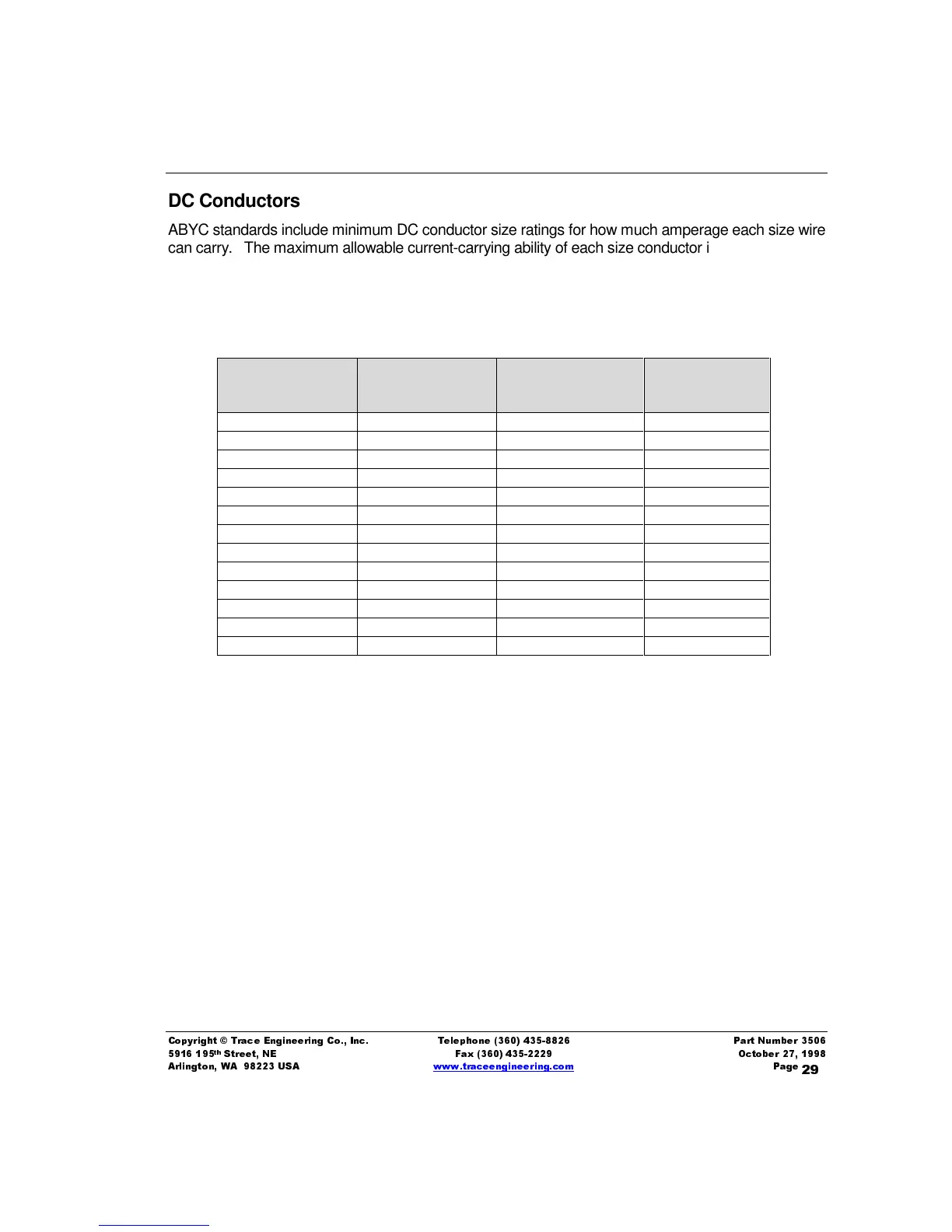

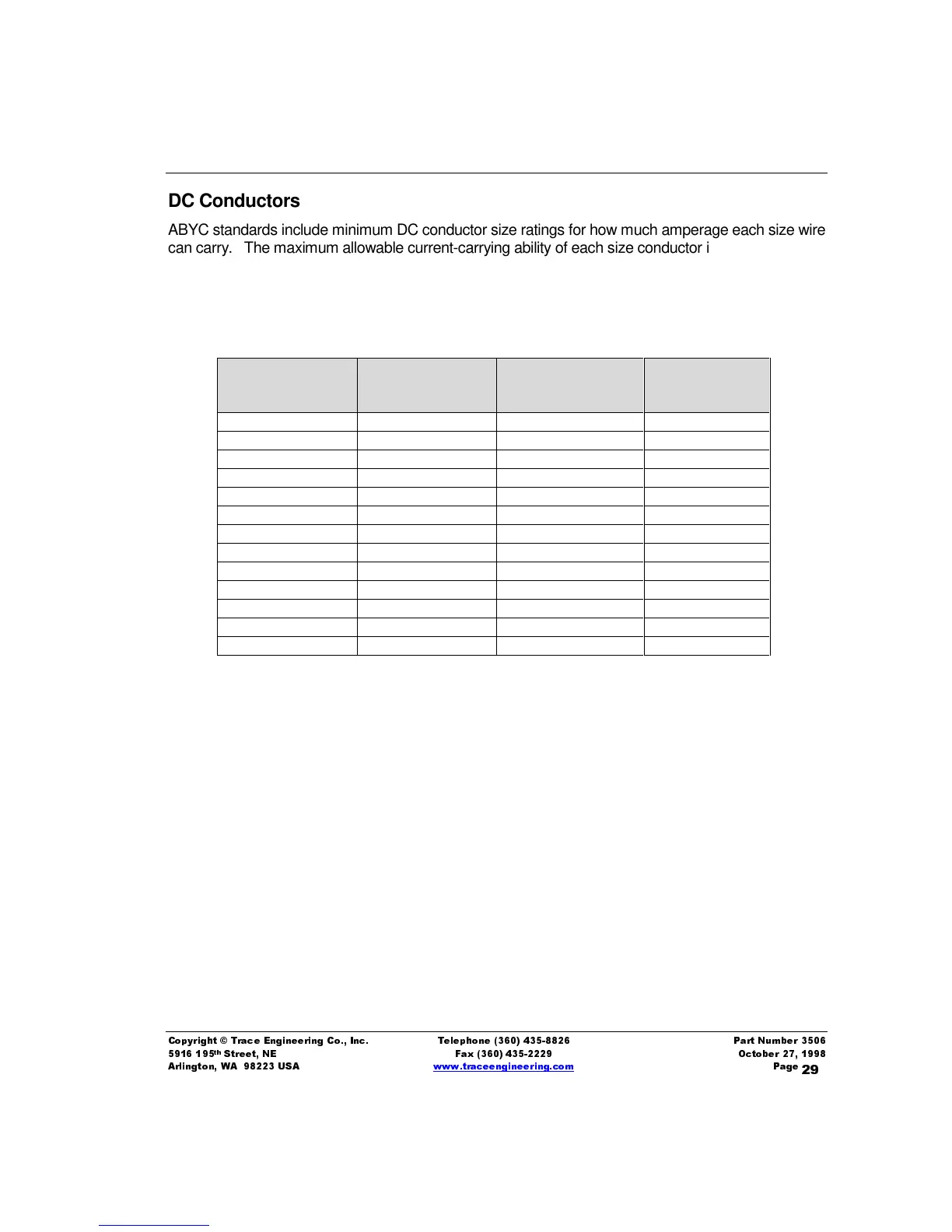

ABYC standards include minimum DC conductor size ratings for how much amperage each size wire

can carry. The maximum allowable current-carrying ability of each size conductor is listed in the

following table.

Table 6, Maximum Amperage for Conductors Under 50 Volts at 105ºC

AWG Wire Size Metric Wire Size

Amperage

Outside Engine

Spaces

Amperage in

Engine Spaces

18 .8 20 17

16 1 25 21.3

14 2 35 29.8

12 3 45 38.3

10 5 60 51

8 8 80 68

6 13 120 102

4 19 160 136

2 32 210 18.5

0 50 285 242.3

00 62 330 280.5

000 81 385 327.3

0000 103 445 378.3

DC Cabling Connections

Color-code your battery cables with colored tape or heat shrink tubing. The standard is red for

positive (+) and black for negative (-).

Cables must have soldered and crimped, or crimped copper compression lugs unless aluminum

mechanical lugs are used. Soldered connections alone are not acceptable. We suggest using high

quality, UL-listed Trace Engineering battery cables. These cables are available in a specific

assortment of sizes from 1 ½ to 10 feet, and in 2/0 or 4/0 AWG. They are color-coded and have

pressure crimped, sealed ring terminals. Contact your Trace dealer to order.

Figure 7, Battery to Inverter Cable Connection

illustrates proper connections for the Mariner

inverter/chargers. Points of caution are:

ä Do not connect the battery negative (-) cable to the vessel safety ground; connect it to the

battery negative terminal of the inverter.

ä Do not connect equipment DC negatives to the safety ground, connect only to the negative

bus of the DC load center.

Loading...

Loading...