Coil Piping and Connections

CLCH-SVX009J-EN 39

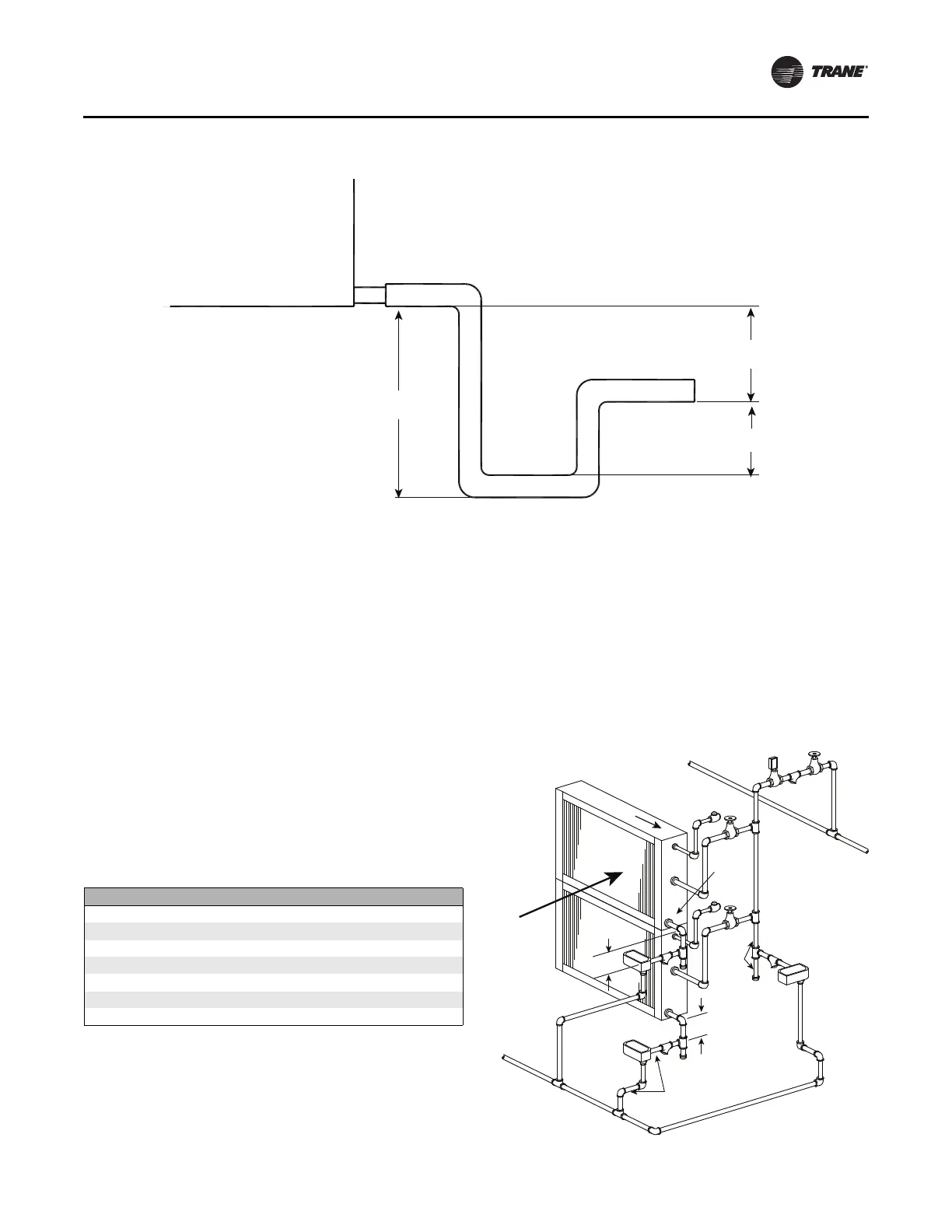

Steam Coil Piping

Air handlers fitted with steam coils have labeled holes for

piping penetrations. Figure 46 illustrates a typical steam

coil piping configuration. See Table 9 for the codes of

system components in these figures.

The coil condensate return line must be piped full size of

the condensate trap connection, except for a short nipple

screwed directly into the coil header’s condensate return

tapping. Do not bush or reduce the coil return trapping

size.

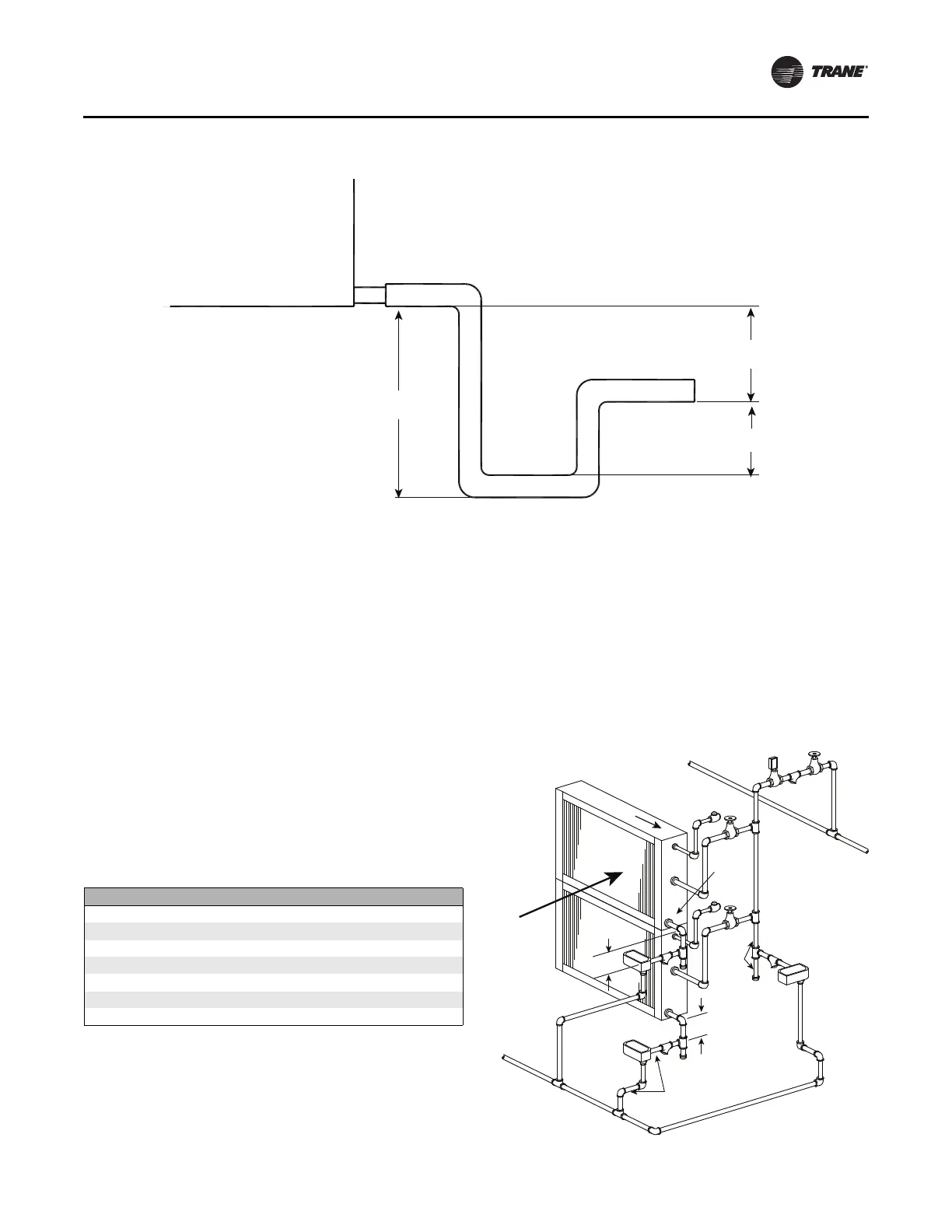

Figure 45. Drain pan trapping for negative and positive pressure applications

H

J

L

Section under negative pressure

L = H + J + pipe diameter where:

H = 1 inch for each inch of negative

pressure plus 1 inch

J = 1/2 H

Section under positive pressure

L = H + J + pipe diameter where:

H = 1/2 inch (minimum)

J = 1/2 inch plus the unit positive

static pressure at coil discharge

(loaded filters)

Table 9. Code of system components for piping figures

Code System component

FT Float and thermostatic steam trap

GV Gate valve

OV Automatic two-position (ON-OFF) control valve

VB Vacuum breaker

ST Strainer

AV Automatic or manual air vent

MV Modulating control valve

Figure 46. Typical piping for Type NS steam coils and

horizontal tubes for horizontal airflow

Pitch down

VB

GV

GV

VB

GV

MV

ST

Steam main

Full size

of main

ST

Full size

of coil

connection

ST

12 in. min.

Return main

12 in. min.

FT

FT

Full size of

steam trap

connection

FT

ST

Airflow

Loading...

Loading...