10 18-AD47D1-1B-EN

Installer’s Guide

When a refrigerant leak of the indoor coil is detected, the refrigerant

leak detection system turns on the blower of the furnace to dilute

leaked refrigerant.

The installer must verify that the indoor airow setting is sucient

to dilute leaked refrigerant. The nominal airow settings for rst-

stage cooling, rst-stage heat pump, and rst-stage furnace heat

should not be less than shown in the minimum airow table below.

NOTE:

The airow setting should be veried by comparison to

the airow at the lowest listed external static pressure

for the setting. Refer to the airow table provided by the

manufacturer of the furnace.

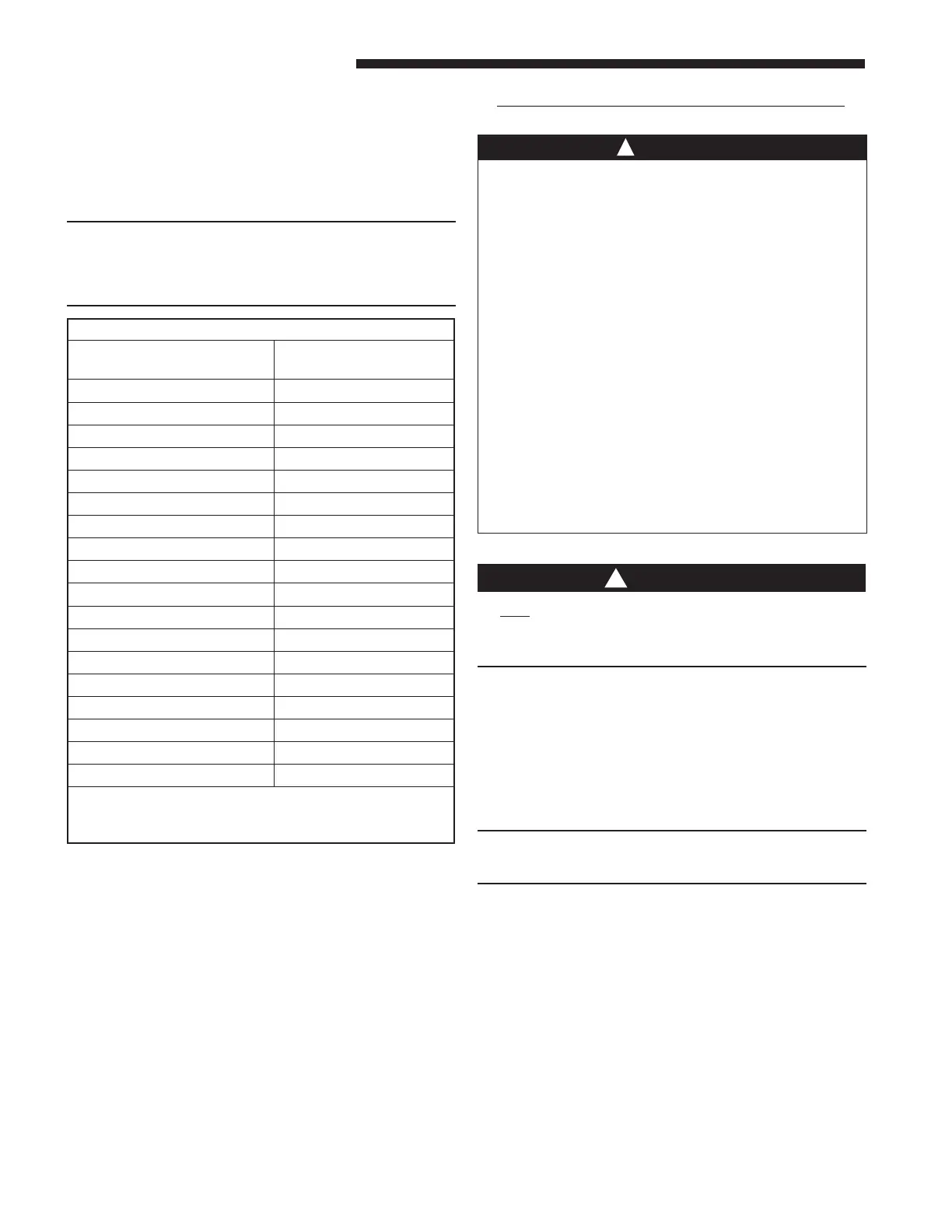

Minimum Airow Setting

System

refrigerant charge (lb) +

Minimum Airow Setting

(CFM)

less than 4 no mimimum

4 108

5 135

6 162

7 189

8 216

9 244

10 271

11 298

12 325

13 352

14 379

15 406

16 433

17 460

18 487

19 514

20 541

+ The system refrigerant charge is the total system charge

which is marked on the system according to the instructions

provided by the manufacturer of the outdoor unit.

K. INSTALLING / BRAZING REFRIGERANT LINES:

RISK OF FIRE!

Failure to following this warning could result in serious

injury, death, or property damage.

The following requirements apply to the room where the

cased coil is installed:

• All combustion appliances located in the same

room that have continuous pilot lights are equipped

with an effective flame arrest.

• Auxiliary devices which may be a potential ignition

source, such as hot surfaces or electric switching

devices, shall not be installed in the connecting

ductwork unless they have been approved by

the manufacturer or declared suitable with the

refrigerant used.

• All indoor field-made joints of the field piping have

been checked for refrigerant leaks after charging

using an electronic leak detector calibrated for

R-454B having a sensitivity of 5 grams per year or

better.

• The room is constructed to ensure that should any

refrigerant leak it will not stagnate and create a fire

hazard.

Do NOT open refrigerant valve at the outdoor unit until the

refrigerant lines and coil have been brazed, evacuated, and

leak checked. This would cause contamination of the refriger-

ant or possible discharge of refrigerant to the atmosphere.

1. The following steps are to be considered when installing

the refrigerant lines:

a. Determine the most practical way to run the lines.

b. Consider types of bends to be made and space

limitations.

c. Route the tubing making all required bends and

properly secure the tubing before making final

connections.

NOTE:

Refrigerant lines must be isolated from the structure and

the holes must be sealed weather tight after installation.

Loading...

Loading...