6 18-AD47D1-1B-EN

Installer’s Guide

E. RECOMMENDATION:

If a coil is part of the total system installation, use the Installer’s

Guide packaged with the furnaces, outdoor sections, and

thermostat for physically installing those components.

F. FURNACE IN UPFLOW POSITION :

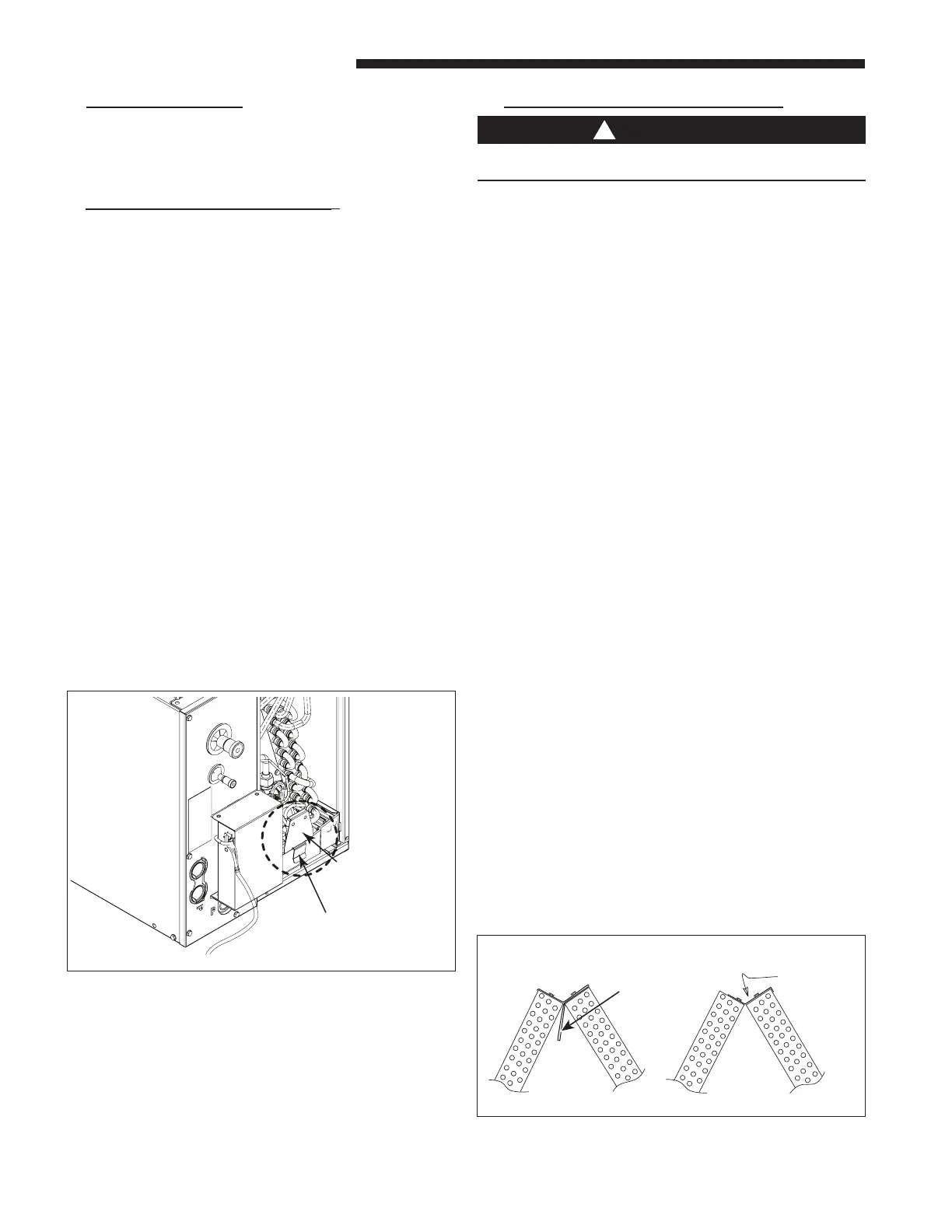

1. UPFLOW COIL CONVERSION: While not required,

optional removal of some coil components will maximize

airow eciency.

a. Remove the coil by sliding the coil out of the coil

enclosure.

b. Optional but recommended: Remove the factory

installed two-piece bae assembly from the top of

the coil by removing the 5/16” hex head screws. See

Figure 3. Replace only the top bae using the same

screws previously provided.

c. Optional but recommended: On 5TXCA009AS and

5TXCD010AS only, remove the (2) outer water diverter

baes by removing the 5/16” hex head screws. See

Figure 10.

d. Optional for maximum eciency: Remove the

horizontal drain pan from the coil and discard.

2. UPFLOW GAS FURNACE

a. Apply gasket material (duct seal eld supplied) to ALL

mating surfaces between the furnace and the coil case.

b. Set the coil case on top of the furnace. Connect the

ductwork to the coil case using eld supplied screws.

c. Secure the coil case to the furnace using factory

provided standos and screws. See Figure 4.

Seal for air leaks as required.

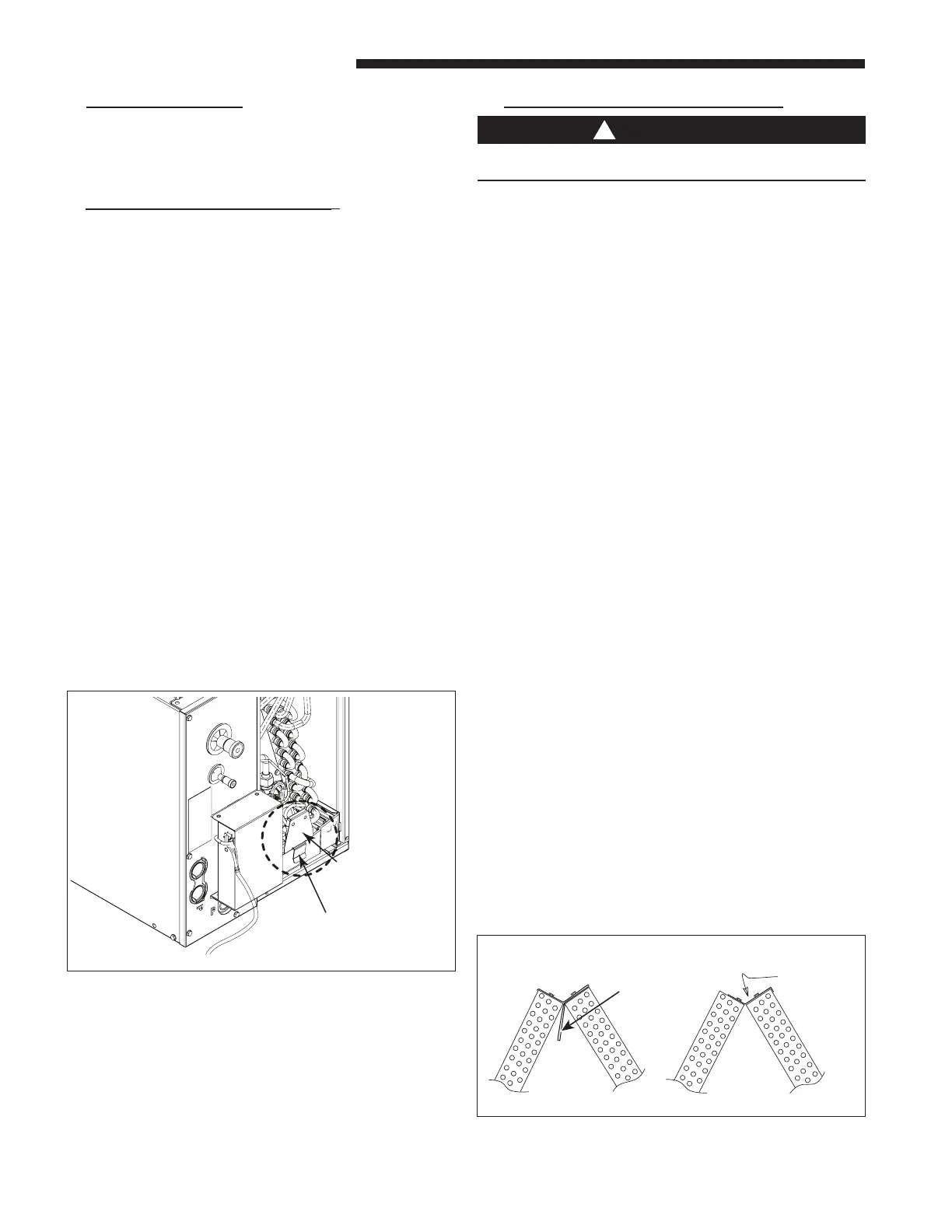

d. Ensure the sensor is secured to the primary drain pan

as shown in Figure 2.

Refrigerant Sensor

should be seated

fully on pan

Dimension from the bottom of

the Drain Pan to the bottom of

the Sensor should be 0.8" max

Figure 2

G. FURNACE IN DOWNFLOW POSITION:

To prevent damage to pan, ensure Heat Shield is

assembled to Horizontal Drain Pan. See Figure 9.

1. DOWNFLOW COIL CONVERSION: While not required,

optional removal of some coil components will maximize

airow eciency.

a. Remove the coil by sliding the coil out of the coil

enclosure.

b. Optional but recommended: Remove the factory

installed two-piece bae assembly from the top of

the coil by removing the 5/16” hex head screws. See

Figure 3. Replace only the top bae using the same

screws previously provided.

c. Optional for maximum eciency: Remove the

horizontal drain pan from the coil and discard.

d. Ensure the sensor is secured to the primary drain pan

as shown in Figure 2.

2. DOWNFLOW GASKET INSTALLATION (OPTIONAL): For

unusually humid applications that expect prolonged operation

above 70% RH, it is recommended to use the BAYGSKT001A0

gasket kit to prevent water from forming on the bottom of the

drain pan and dripping into the supply ductwork.

a. Lay the coil on its back side.

b. Locate the 4" wide gasket material found in

BAYGSKT001A0.

c. Attach the 4" gasket material to three sides of the

bottom of the drain pan as shown in Figure 5. Make

sure to start by matching up the edge of the gasket

material to the inner edge of the drain pan by the coil

ns and working outwards.

d. The gasket material can be cut or ripped easily so that

it can be tailored to t. The gasket material must cover

the three sides along the entire length of the coil as

shown in Figure 5.

3. DOWNFLOW GAS FURNACE

When a coil is used with a downow furnace, a subbase

is not required between the coil case and combustible

ooring.

a. Place the coil case on the furnace supply air plenum.

b. Secure the coil case to the plenum.

c. Set the furnace on top of the coil case, making sure

that the back side of the discharge opening is snug up

against the duct ange at the top rear of the coil case.

d. Secure the coil case to the furnace and seal for air

leaks as required.

Figure 3

Loading...

Loading...