FAXA-SVX01B-EN 75

Maintenance

maintenance

procedures

Total Energy Wheel

Protect the total energy wheel by using a

30% filter to keep dust and dirt from the

heat transfer surface. The wheel is

somewhat self cleaning through its

normal action of rotating in and out of

counter-current airflow streams. If the

wheel becomes dirty, clean it by blowing

out the unit with compressed air, 20 psig

maximum.

Cleaning the Total Energy Wheel

Trane total energy wheels are self-

cleaning with respect to dry particles.

Smaller particles pass through the wheel.

Larger particles land on the surface and

are blown clear as the wheel turns into

the opposite airflow path. For this reason,

the primary cleaning required for the

total energy wheel is to remove the oil-

based aerosol film that collect on the

surface. Such films can close off micron-

sized pores at the surface of the desiccant

material, reducing its ability to absorb and

desorb moisture. Periodically record the

air temperatures entering and leaving

the energy wheel to detect changes in

performance.

In a reasonably clean indoor environ-

ment, such as a school or office building,

experience shows that reductions of

airflow or loss of sensible effectiveness

may not occur for ten or more years.

Where there is moderate tobacco smoke

or within cooking facilities, reduction in

effectiveness can occur much faster. In

applications experiencing high levels of

smoke, the energy transfer surfaces may

require cleaning as often as every six

months. Similar washing cycles may also

be appropriate for industrial applications,

such as welding or machining operations,

involving ventilation of high levels of

smoke or oil-based aerosols.

Proper cleaning of the energy wheel

should restore latent effectiveness to

near original performance.

Clean the total energy wheel as neces-

sary to maintain optimum airflow. When

washing/cleaning the wheel, take care

not to allow water or detergent to come

into contact with any of the electrical

components. Drain holes in the wheel

rack are capped and can be removed

during cleaning. Replace caps to avoid air

bypass. The single draw hole located

upstream of the outside air filters should

be utilized for draining, during cleaning.

Ensure no water, moisture, or excess

detergent is left in the energy wheel

compartment. Use a wet-vac vauum

cleaner to remove water/moisture as

needed.

Air Filter Replacement

Filter access doors are on both sides of

the unit. To replace filters, remove the

dirty elements and install new filters

(ASHRAE 30% or higher) with the filter

directional arrows pointing toward the

fan. Verify that no air bypasses the filters.

Inspecting and Cleaning the Drain Pan

Check the condensate drain pan and

drain line to ensure that the condensate

drains properly at least every six months

or as dictated by operating experience.

If evidence of standing water or conden-

sate overflow exists, take steps to identify

and remedy the cause immediately.

Refer to the trouble shooting section of

this manual for possible causes and

solutions. If microbial growth is evident in

the drain pan, remove and clean it

immediately. Clean drain pans using the

following procedure:

1. Disconnect all electrical power to the

unit.

2. Don the appropriate personal

protective equipment (PPE).

3. Remove all standing water.

4. Use a plastic scraper or other tools to

remove any solid matter. Remove solid

matter with a vacuum device that

utilizes high efficiency particulate

arrestance (HEPA) filters with a

minimum efficiency of 99.97% at 0.3

micron particle size.

5. Thoroughly clean the contaminated

area(s) with an EPA-approved sanitizer

specifically designed for HVAC use.

Carefully follow the sanitizer

manufacturer’s instructions regarding

product use.

6. Immediately rinse the drain pan

thoroughly with fresh water to prevent

potential corrosion from the cleaning

solution.

7. Allow the unit to dry thoroughly before

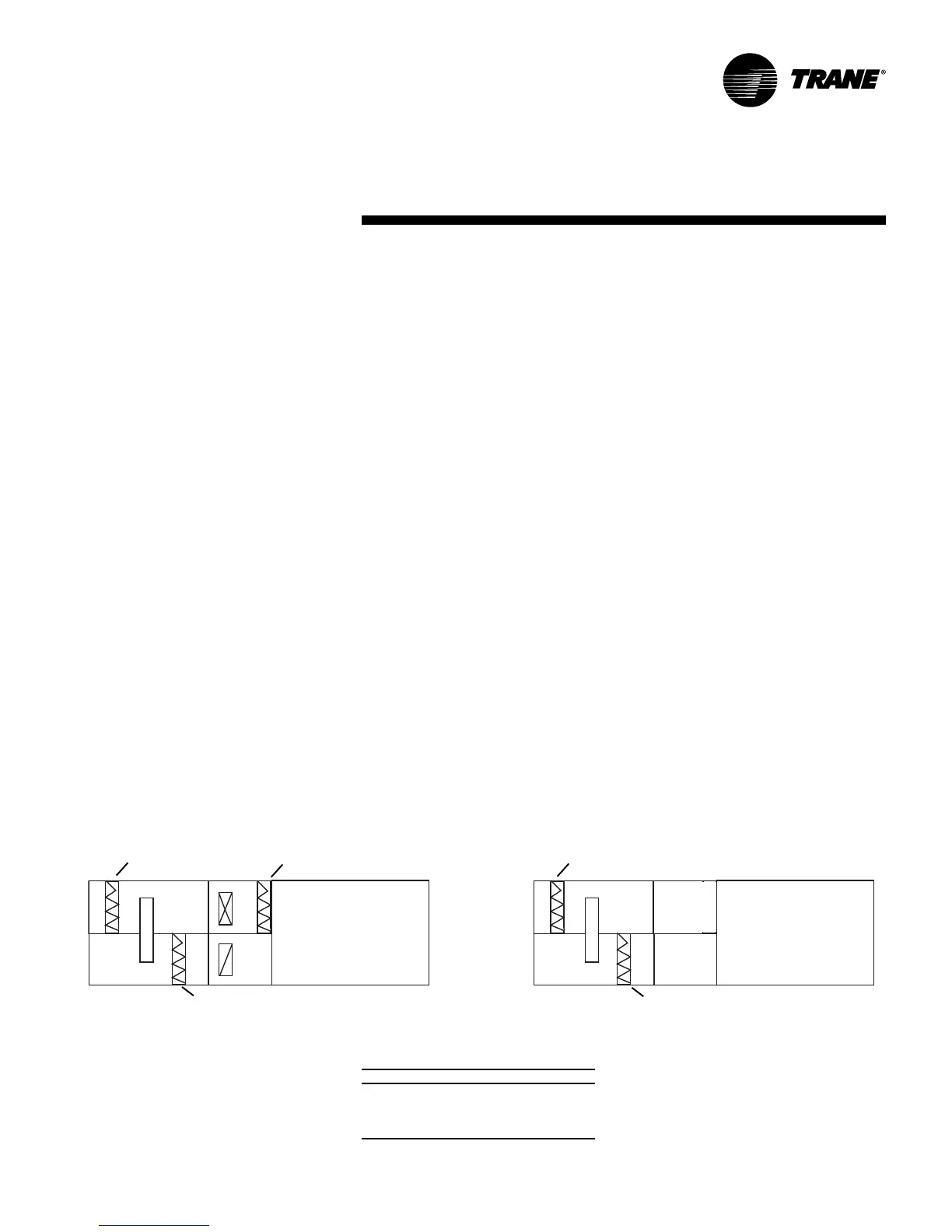

Figure M-MP-1. Filter placement three racks

with return

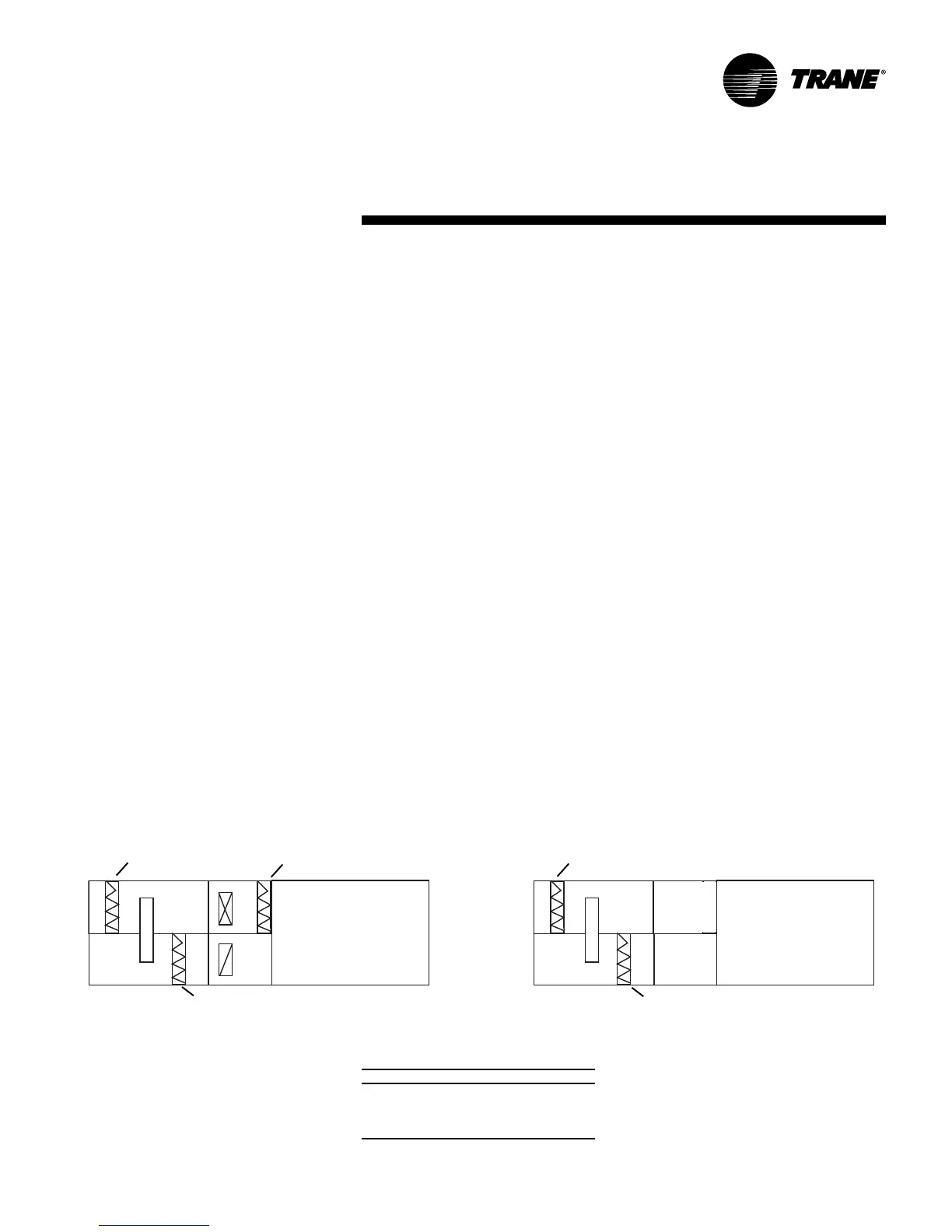

Figure M-MP-2. Filter placement two racks

without return

Table M-MP-1. Filter sizes, in.

unit size OA EA main unit

031 20 x 16 20 x 16 20 x 16

040 20 x 16 20 x 16 20 x 16

051 25 x 20 25 x 16 24 x 24

066 25 x 20 20 x 16 20 x 16

Note: Filters are ASHRAE 30% or higher.

OA

OA

EA

EA

UNIT

FILTER

Loading...

Loading...