FAXA-SVX01B-EN 77

Maintenance

maintenance

procedures

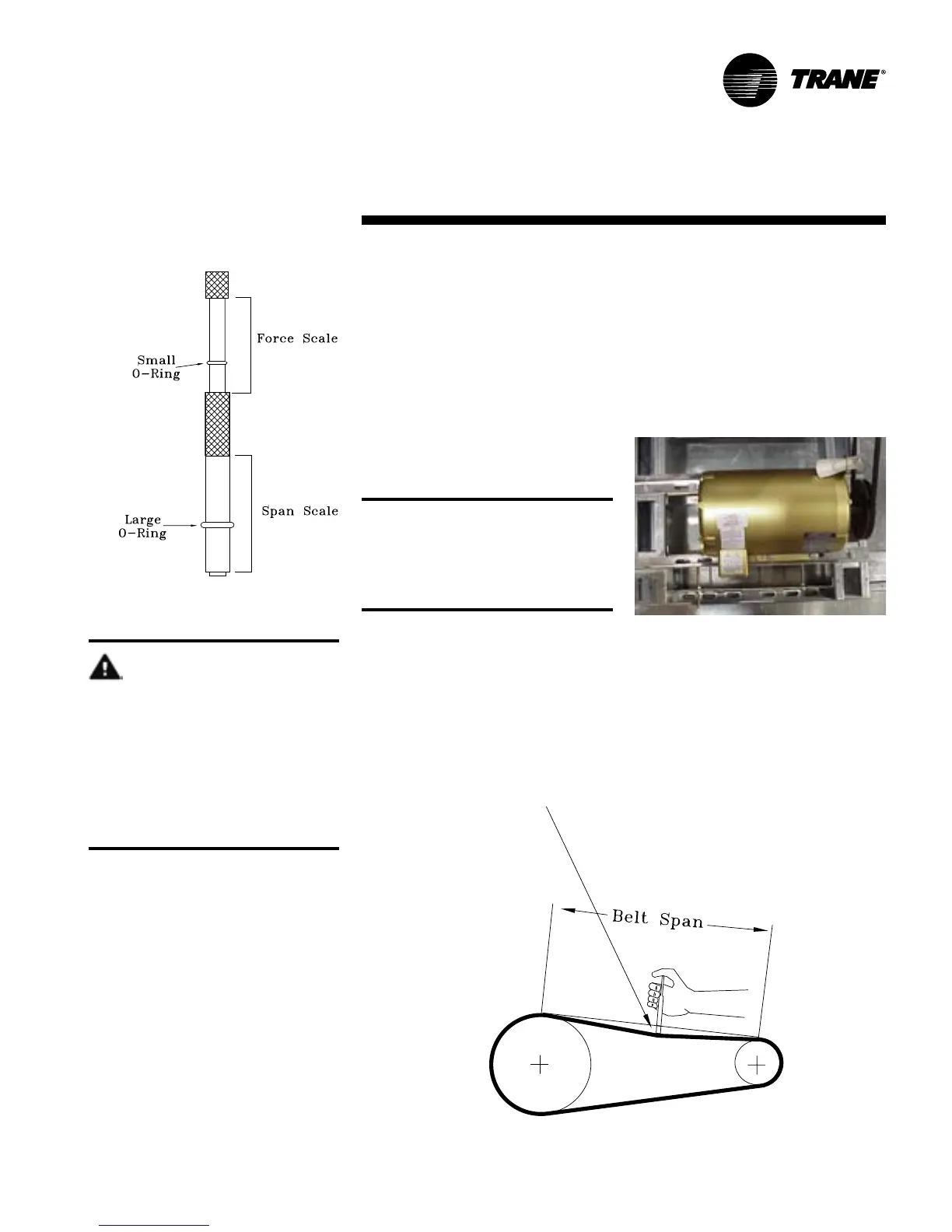

Figure M-MP-6. Fan belt adjustment

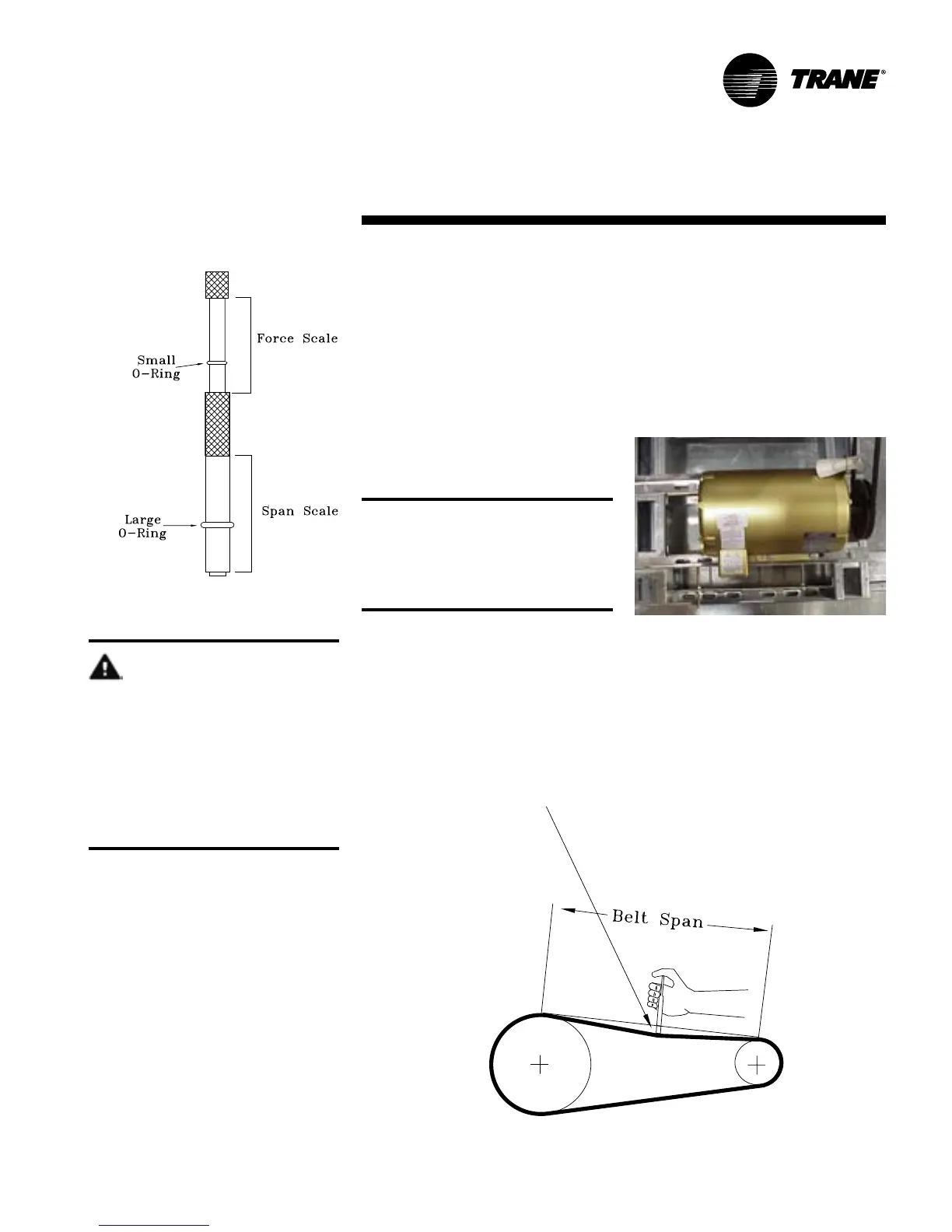

Figure M-MP-4. Belt tension gauge

Adjusting Fan Belt Tension

To adjust the fan belt tension, refer to

Figure M-MP-6, following the procedure

below.

1. Loosen bolts on both sides of the

sliding motor base.

2. Loosen nuts (as required for motor

horsepower) to slide the motor on its

mounting plate in the proper direction

to add or relieve belt tension.

3. Adjust nuts and bolt. Do not stretch the

belts over the sheaves.

4. Retighten all nuts and bolts.

5. Verify tension is adjusted properly.

CAUTION

Belt tension!

Do not over-tension belts. Excessive

tension will reduce fan and motor

bearing life, accelerate belt wear, and

possibly cause shaft failure.

Recommended belt tension range values

are on the unit fan scroll. To access the

fan scroll, face the right-hand side of the

deflection = belt span/64

unit and open the supply fan access door.

The belt tension label is on the top right-

hand corner of the fan scroll. The correct

operation tension for a V-belt drive is

thelowest tension at which the belt will

not slip under the peak load conditions. It

may be necessary to increase the tension

of some drives to reduce flopping or

excessive startup squealing.

Figure M-MP-5. Fresh air unit fan plate

WARNING

Rotating components!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure power

cannot be inadvertently energized.

Failure to disconnect power before

servicing can cause death or serious

injury.

Loading...

Loading...