RT-SVX063G-EN

103

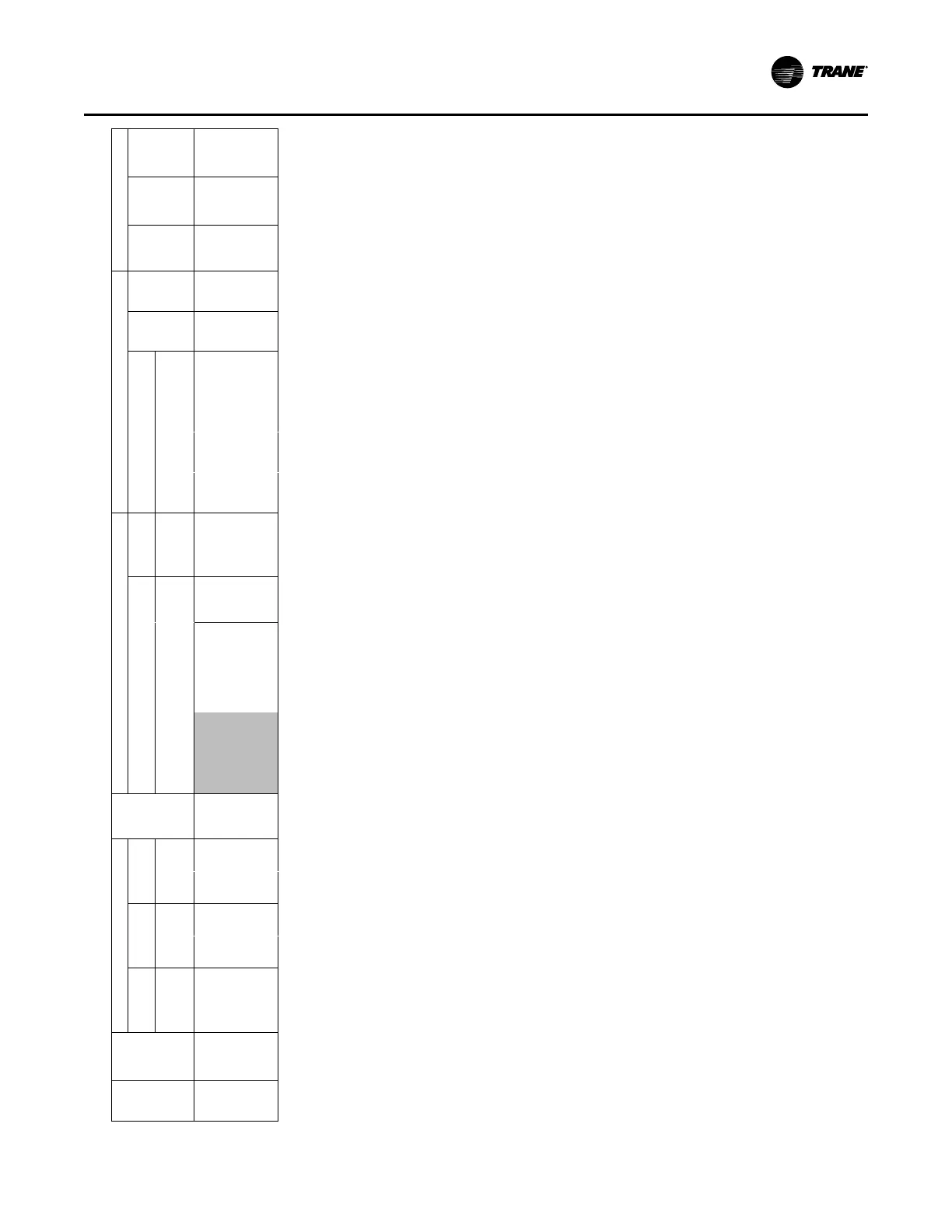

Table 55. Component static pressure drops (in. H

2

O) (continued)

Tons

CFM

Std

Evap Coil

HGRH

Heating System

Filters Economizer

Standard

High

Efficiency

Variable Gas Electric

Pre Evap Panel

Pre

Evap

Cart

Final

Cart

Return

Air

Outside

Air W/O

Traq

Outside

Air W/

Traq

Dry

Wet

Dry

Wet

Dry

Wet

250

MBh

350

MBh

500

MBh

850

MBh

1200

MBh

All kW

2"

Merv 4

2"

Merv 8

4"

Merv 8

4"

Merv

14

75

15000 0.47 0.51 0.24 0.26 0.24 0.26 0.03 0.56 0.70 0.63 0.26 0.08 0.14 0.13 0.38 0.34 0.38 0.22 0.25 0.25

18000 0.58 0.00 0.29 0.35 0.28 0.35 0.04 0.80 1.01 0.90 0.38 0.11 0.21 0.18 0.55 0.49 0.55 0.32 0.36 0.36

21000 0.68 0.88 0.32 0.45 0.34 0.45 0.06 1.09 1.38 1.23 0.52 0.15 0.28 0.25 0.74 0.66 0.75 0.44 0.49 0.49

24000 0.85 1.08 0.39 0.55 0.39 0.55 0.08 1.42 1.80 1.60 0.68 0.20 0.37 0.33 0.97 0.87 0.98 0.57 0.63 0.63

27000 1.03 1.29 0.48 0.67 0.48 0.67 0.10 1.80 2.28 2.03 0.86 0.25 0.47 0.41 1.23 1.10 1.24 0.73 0.80 0.80

30000 1.22 1.51 0.57 0.79 0.57 0.79 0.12 2.22 2.81 2.50 1.06 0.31 0.58 0.51 1.52 1.35 1.53 0.90 0.99 0.99

Notes:

1. Static pressure drops of accessory components must be added to determine total static pressure for fan selections.

2. Gas heat section maximum temperature rise of 60°F.

3. Economizer static pressure value for sizing supply fan is the highest of the following: a) Return air static pressure drop plus customer return duct static pressure and b) Outside air static pressure drop.

Performance Data

Loading...

Loading...