124

RT-SVX063G-EN

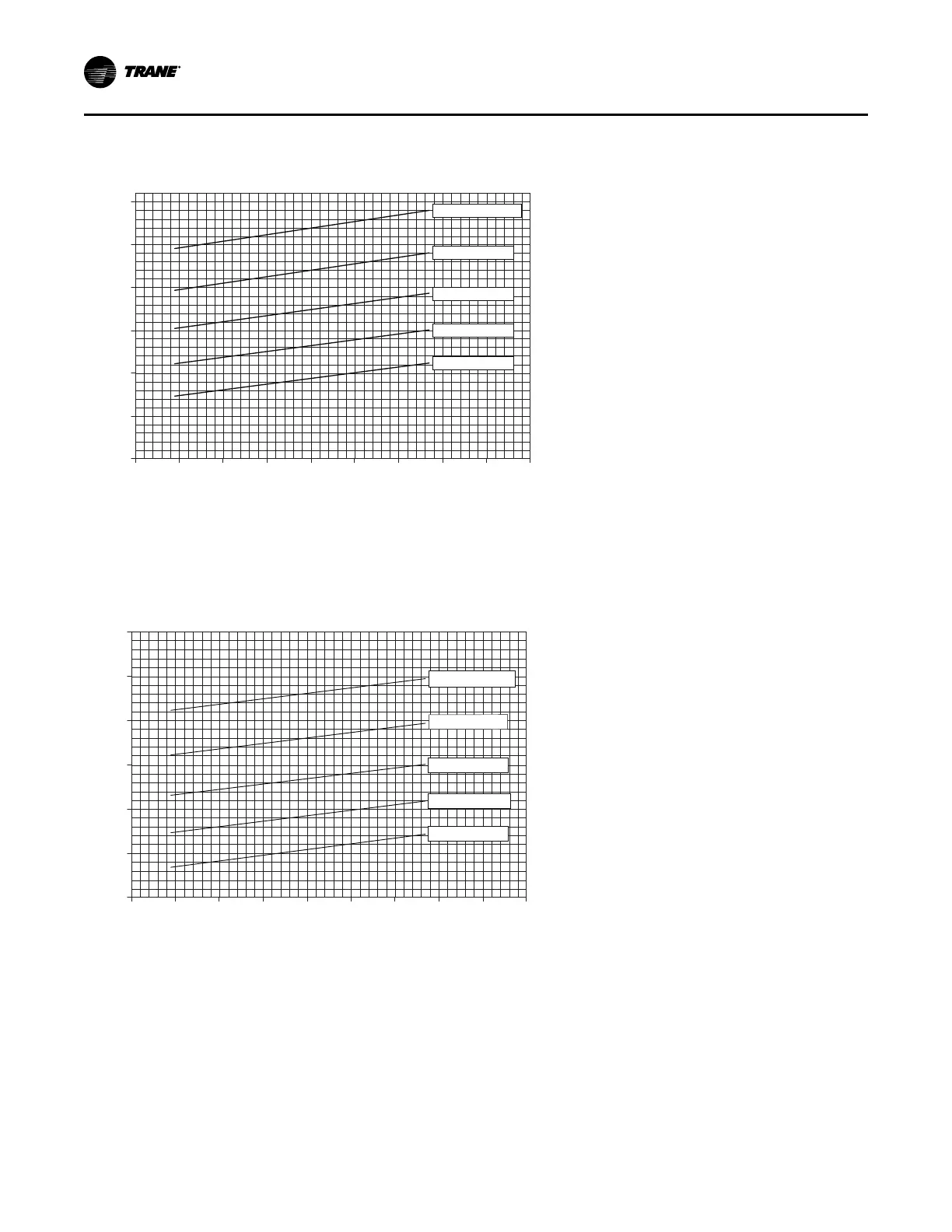

Figure 88. Pressure curve — 75 tons high efficiency

Discharge Pressure, PSIG

Suction Pressure, PSIG

200

250

300

350

400

450

500

90 100 110 120 130 140 150 160 170 180

95°F Ambient

85°F Ambient

75°F Ambient

65°F Ambient

105°F Ambient

75T High Efficiency

Note: Full load acceptable subcooling range: 13-23°F

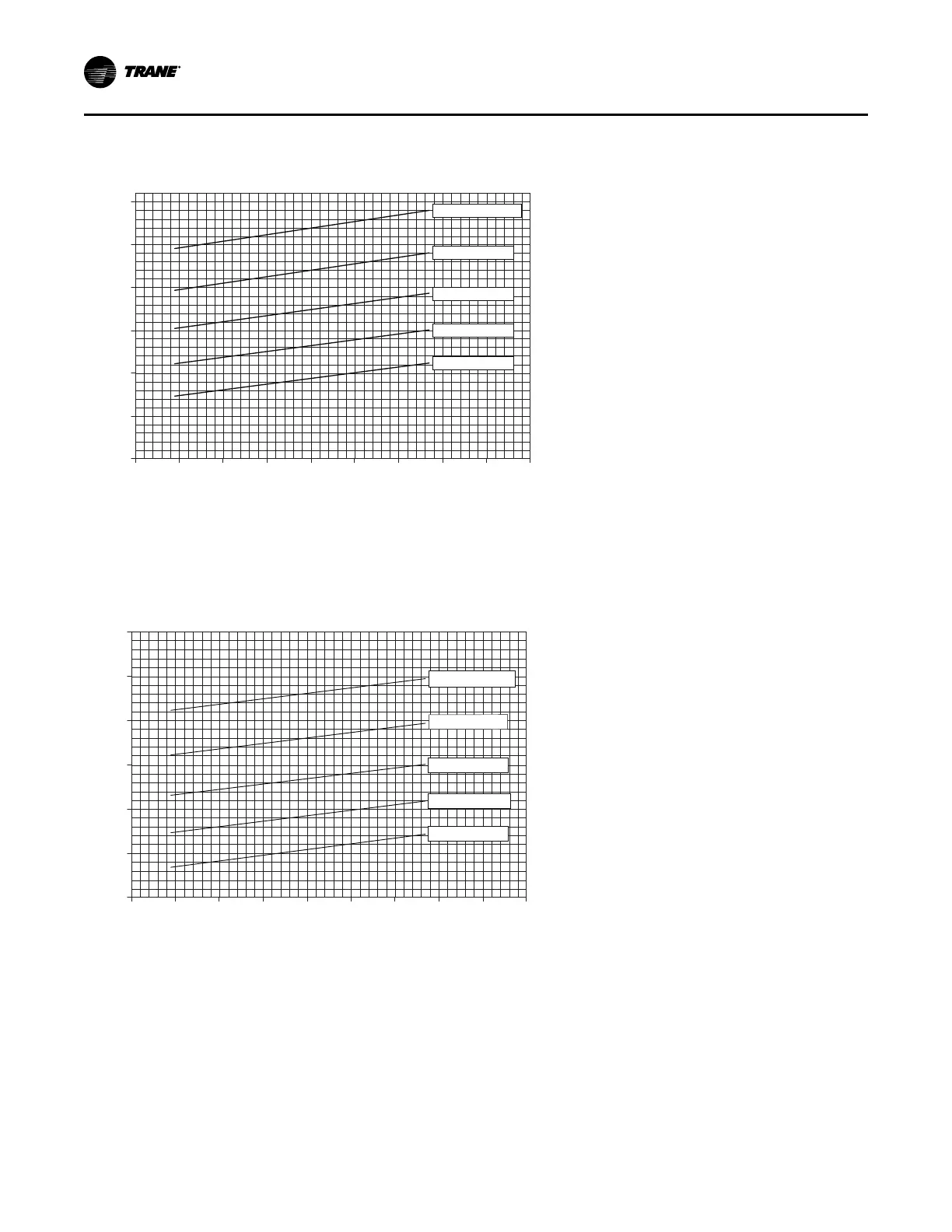

Figure 89. Pressure curve — 75 tons eFlex variable speed

250

300

350

400

450

500

550

90 100 110 120 130 140 150 160 170 180

Discharge Pressure, PSIG

Suction Pressure, PSIG

105°F Ambient

95°F Ambient

85°F Ambient

75°F Ambient

65°F Ambient

75T eFlex Variable Speed - circuit 1 only

(Use 75T Standard Capacity for circuit 2)

Note: Full load acceptable subcooling range: 13-23°F

Compressor Oil

Refer to Table 69, p. 126 for the appropriate scroll

compressor oil charge. Remove and measure oil from any

compressor replaced. Adjust oil in replacement

compressor to prevent excessive oil in system. Anytime a

compressor is replaced, the oil for each compressor within

the manifold must be replaced.

The scroll compressor uses Trane OIL00079 (one quart

container) or OIL00080 (one gallon container) without

substitution. Discoloration of the oil indicates that an

abnormal condition has occurred. If the oil is dark and

smells burnt, it has overheated because of the following:

• Compressor operating at extremely high condensing

temperatures

• High superheat

• A compressor mechanical failure

• Occurrence of a motor burnout.

Service and Maintenance

Loading...

Loading...