Chiller Troubleshooting

ARTC-SVX002A-EN 63

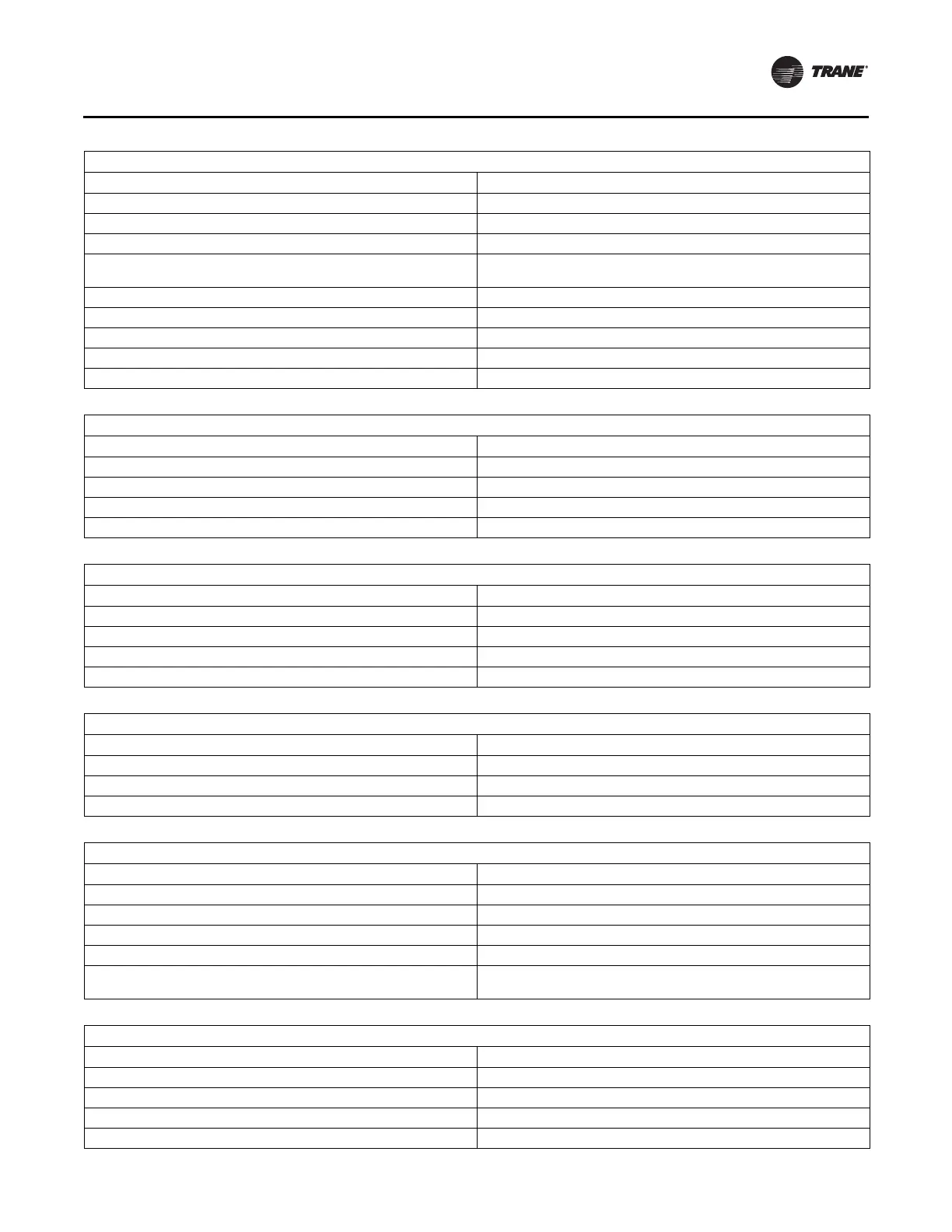

2. Symptom: Compressor will not run

Possible Causes Potential Solutions

Compressor will not run Assure all breakers and switches are on

Main switch open or circuit breakers open Check circuits and motor winding for shorts or grounds

Fuse is blown Replace fuse or reset breakers after fault is corrected

Investigate for possible overloading.

Overloads are auto-reset. Monitor to assure the overload does not re-

occur.

Thermal overload breaker tripped or fuses blown Repair or replace

Defective contactor or coil Determine type and cause. Correct fault before resetting safety.

System shut down by safety devices Repair or replace coil

Liquid line solenoid will not open Check motor for open circuit, short circuit, or motor burnout

Motor electrical trouble Tighten all terminal screws

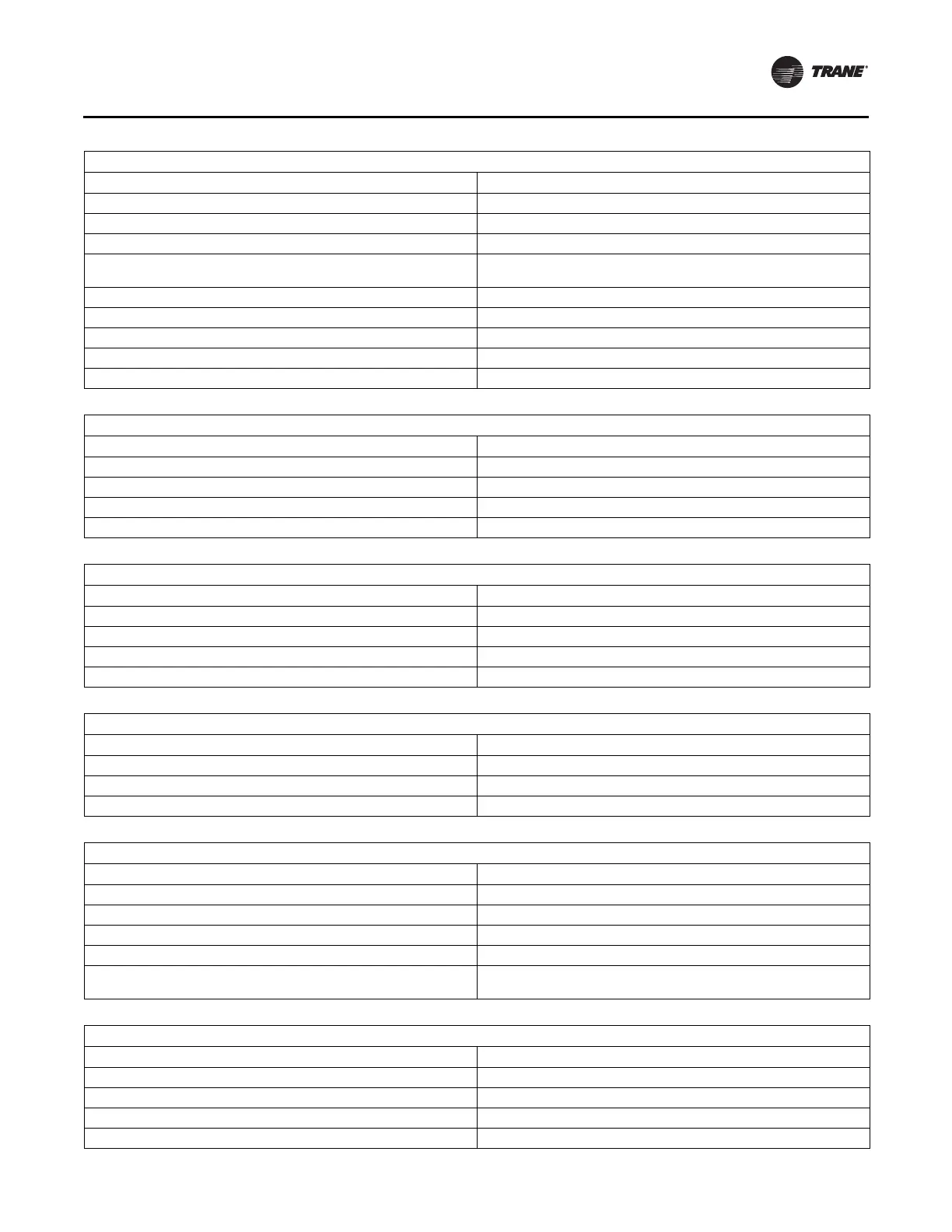

3. Symptom: Compressor has excessive noise or vibration

Possible Causes Potential Solutions

Flooding of refrigerant into crankcase Check setting of expansion valve

Improper discharge piping support Relocate, add, or remove supports

Improper or worn compressor supports Replace supports

Worn compressor Replace or rebuild compressor

4. Symptom: Compressor will not load or unload

Possible Causes Potential Solutions

Defective capacity control Repair or replace module

Unloader mechanism defective Replace unloader

Faulty thermostat gauge or broken capillary tube Replace thermostat assembly

Stages not properly set for application Reset thermostat setting for operating requirements

5. Symptom: Compressor Loading/Unloading Cycles Too Short

Possible Causes Potential Solutions

Temperature differential set too low (4 °F (2 °C) minimum) Ramp/set temperature set point

Erratic water thermostat device Replace thermostat assembly

Insufficient evaporator water flow Adjust flow rate or remove flow

6. Symptom: Compressor loses oil

Possible Causes Potential Solutions

Low refrigerant charge Check for leaks and repair. Add refrigerant to proper charge.

Gas velocity in risers too low Check riser sizes against compressor gas flow

Oil trapped in line Check pitch of lines and refrigerant velocities

Excessive compression ring blow by Replace or rebuild compressor

Liquid refrigerant

Check compressor superheat. Superheat at the compressor suction

should be approximately 15° F (8.3° C).

7. Symptom: Low refrigeration suction pressure

Possible Causes Potential Solutions

Lack of refrigerant Check for leaks. Repair and add charge.

Evaporator dirty Clean chemically

Clogged suction line or suction gas strainers Clean strainers

Condensing temperature too low Check condensing temperature regulation system

Loading...

Loading...