Chiller Troubleshooting

64 ARTC-SVX002A-EN

Low water temperature Raise set point; check design specification

Compressor will not unload Replace solenoid or controller

Low discharge pressure Refrigerant charge; replace compressor

Expansion valve malfunctioning Reset for proper superheat (10-12 º SH)

Mis-adjusted or defective TXV Adjust or replace valve

Receiver service valve closed

Turn counterclockwise completely. Do not fully backseat if pressure

switch is installed on service port

Compressor service valves closed Dangerous! Turn counterclockwise completely

Clogged liquid line filter-drier Replace cartridges

Excessive glycol concentration Drain, refill (deionized water), retest

Liquid line solenoid restricted or faulty Replace solenoid valve, coil, or internals as necessary

Insufficient chilled water Adjust flow rate across evaporator

Restricted water/glycol line Clean strainers; check manual and electronic valves

Water/glycol mixture contaminated

Intensive cleanup effort needed to identify source of contamination;

external filter may be required

Evaporator tubing clogged or fouled Reverse flush with appropriate chemical solutions

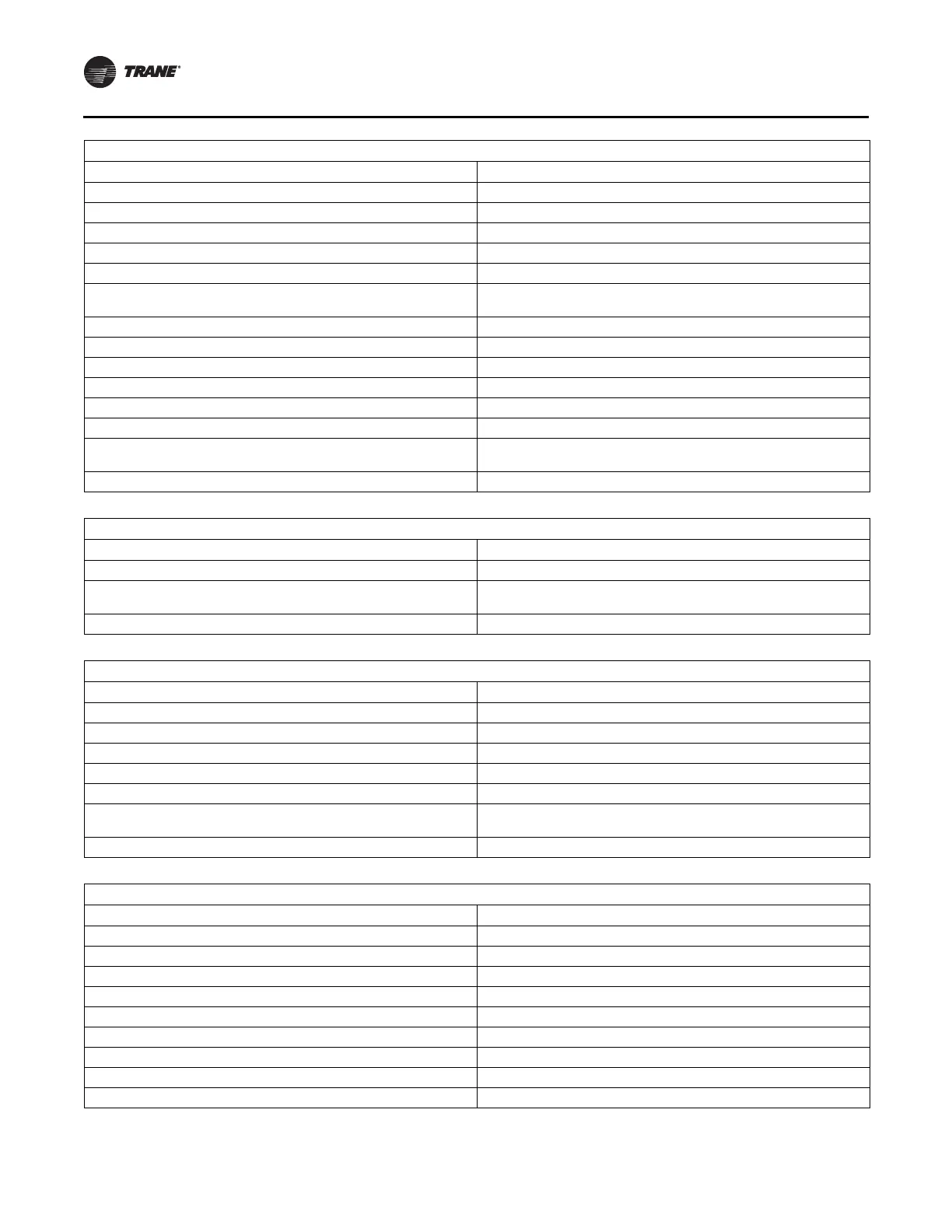

7. Symptom: Low refrigeration suction pressure (continued)

Possible Causes Potential Solutions

8. Symptom: High refrigeration suction pressure

Possible Causes Potential Solutions

Expansion valve opened too far Re-adjust to 10° to 12°

Excessive refrigerant charge

Creates high pressure alarms; reclaim excess refrigerant and verify

proper sub-cooling and superheat.

High water temperature Low refrigerant charge; failing compressor; check design specifications

9. Symptom: Low refrigerant discharge pressure

Possible Causes Potential Solutions

Suction shut off valve partially closed Open valve

Insufficient refrigerant in chiller Check for leaks. Repair and add refrigerant as needed

Compressor operating unloaded See failure of compressor to unload or load up below

Low ambient conditions Check condenser rating tables

Low suction pressure See low pressure below

Condenser pressure regulating valve not properly adjusted

Refer to OEM manufacturer manual for default settings; check equipment

room ambient temperature

Fan cycling controls not properly set Reset cut-in, cut-out settings to conform to design specifications

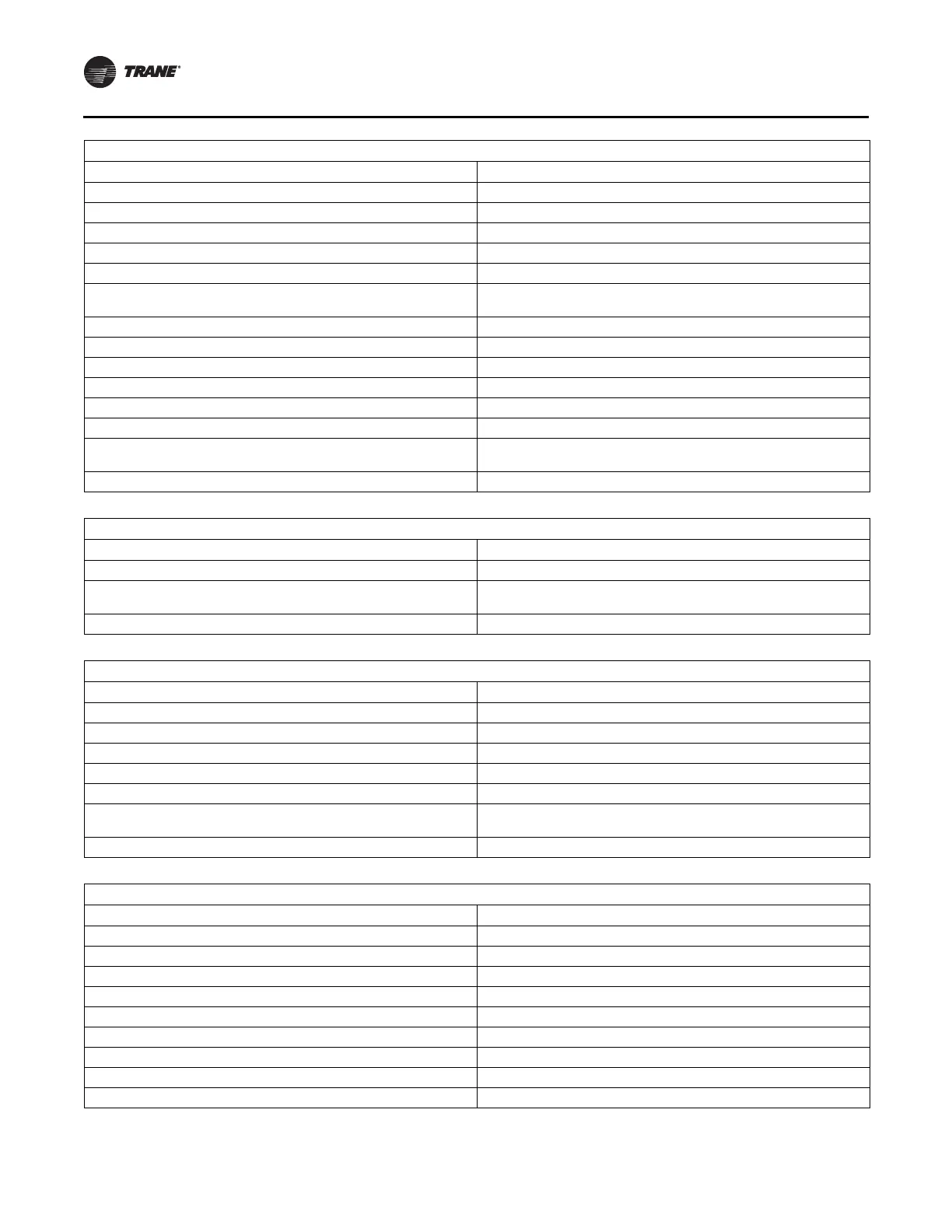

10. Symptom: High refrigerant discharge pressure

Possible Causes Potential Solutions

System overcharged with refrigerant Remove excess refrigerant

Dirty tube and fin surface Clean with compressed air or water spray, use fin comb if fins are bent

Non-condensables in chiller Purge non-condensables.

Fan cycling controls not properly set Reset fan cycle setting; replace motor controller fuse

Condensing fans not operating Reset fan cycle setting; replace motor controller fuse

Restricted bypass line Check valves obstructed; flush line; blow out line with dry nitrogen gas

Discharge shut off valve partially closed Open valve

Condenser is undersized Check condenser rating tables with operating parameters

High ambient conditions exist Check condenser rating tables with operating parameters

Loading...

Loading...