All sections of the flue must be capable of inspection and

removable to enable periodic internal cleaning.

Position the appliance bearing in mind all the instructions

and considerations above.

Important!

All 90 degree changes of direction in the flue pipe must be

either removable or capable of inspection.

THE FLUE PIPE RUN MUST NOT INCLUDE MORE THAN 2-3

METRES OF HORIZONTAL PIPE MUST BE AND NOT MORE

THAN THREE 90° ELBOWS (INCLUDING T’s). IT IS ALSO

ADVISABLE NOT TO EXCEED 8 METRES IN LENGTH WITH THE

PIPE Ø 80mm.

The flue connection on the boiler is 80mm. T R Engineering

Ltd recommends the use of 100mm flue for use with this

appliance, so a 80mm to 100mm adaptor is needed.

3.5 Operating Problems Caused by

Draught Defects in the Flue

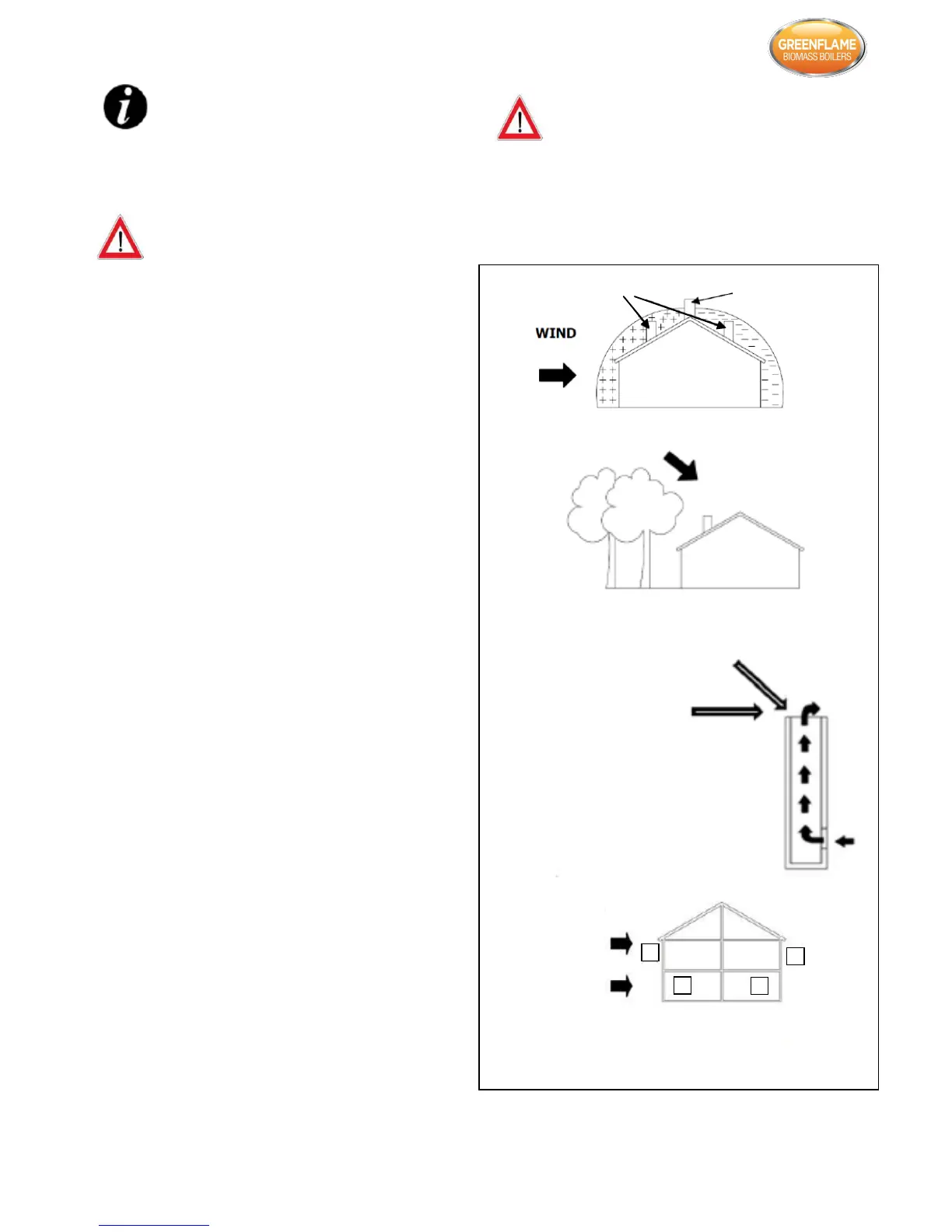

Of all the weather and geographical conditions which affect

the operation of a flue pipe (rain, fog, snow, altitude a.s.l.,

exposure to sunlight, direction of facing), the wind is

unquestionably the most decisive. In fact, along with thermal

depression caused by the difference in temperature inside

and outside of the chimney, there is another type of

depression or over-pressure: dynamic pressure caused by

the wind. An up draught always increases depression and

hence draught. A crosswind increases depression provided

the cowl has been installed properly. A down draught always

decreases depression, at times inverting it.

Besides the direction and force of the wind, the position of

the flue and the cowl with respect to the roof of the building

and the surrounding landscape is important. The wind also

influences the operation of the chimney indirectly by

creating high-pressure and low-pressure zones, not only

outside the building but inside as well. In rooms directly

exposed to the wind (2), an indoor high-pressure area can be

created which can augment the draught in boilers, stoves

and fireplaces, but it can be counteracted by the external

high pressure if the cowl I situated on the side exposed to

the wind (1). On the other hand, in the rooms on the

opposite side from the direction of the wind (3), a dynamic

depression can be created which competes with the natural

thermal depression developed by the chimney, but this can

be compensated for (sometimes) by locating the flue on the

opposite side from the direction of the wind (4).

Loading...

Loading...